A kind of nattokinase microcapsule and preparation method thereof

A technology of soykinase microcapsules and nattokinase, which is applied to microcapsules, biochemical equipment and methods, capsule transportation and other directions, can solve the problems of inability to directly obtain microcapsule powder, complicated steps, etc., and achieves stable enzyme activity and simple process. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

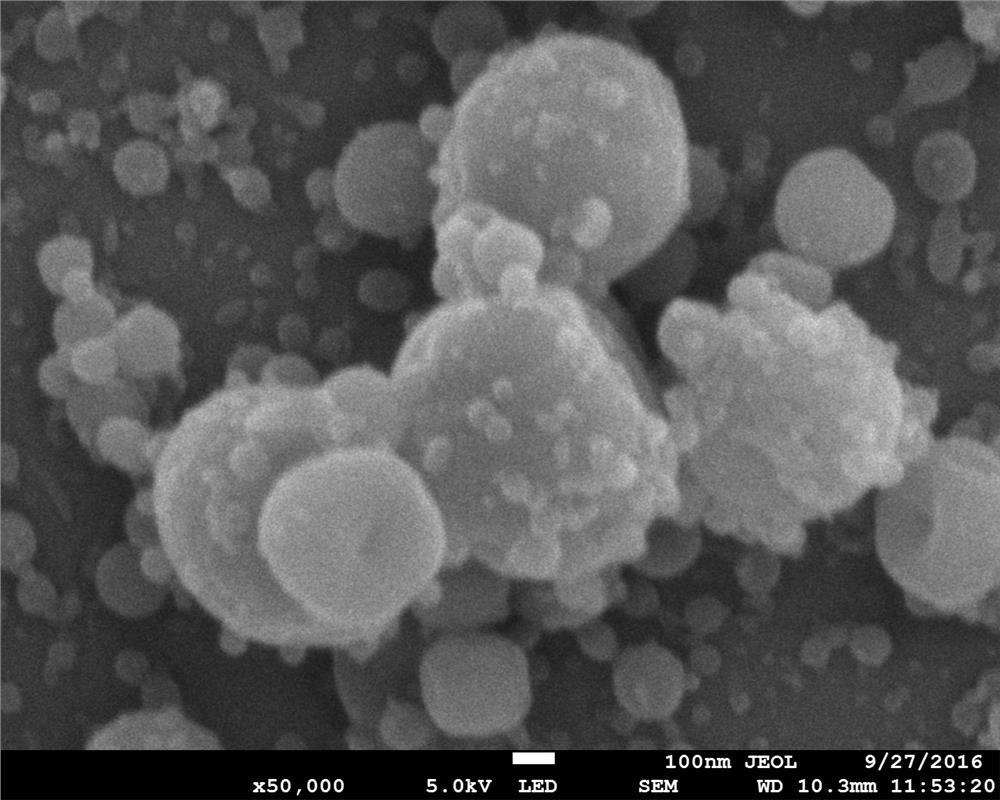

Image

Examples

Embodiment 1

[0030] A preparation method for nattokinase microcapsules, comprising the steps of:

[0031] 1) Selection of raw materials: according to the ratio of whey protein, nattokinase and deionized water as 12g:1g:100mL, weigh whey protein, nattokinase and solvent deionized water for later use;

[0032] 2) Preparation of emulsion: According to the proportioning of raw materials weighed in step 1), whey protein was dissolved in deionized water to prepare a 12% aqueous solution, stirred overnight at room temperature, then added nattokinase and stirred evenly, 6000r Homogenize for 6 minutes under the condition of / min to obtain the emulsion;

[0033] 3) Emulsion electrospray: The emulsion obtained in step 2) is electrosprayed with an electrostatic spray device, and aluminum foil is used as the receiver. The electrospray conditions are: needle head 18G, voltage 13KV, emulsion flow rate 1ml / h, needle tip to accept aluminum foil The distance is 10cm; the solid powder obtained after electro...

Embodiment 2

[0036] A preparation method for nattokinase microcapsules, comprising the steps of:

[0037] 1) Selection of raw materials: according to the ratio of zein, nattokinase and 75wt% ethanol water as 10g: 2g: 100mL, weigh zein, nattokinase and solvent deionized water for later use;

[0038] 2) Preparation of emulsion: According to the proportioning of raw materials weighed in step 1), zein is dissolved in 75wt% ethanol water, and is prepared into a 10% aqueous solution, stirred overnight at room temperature, then added nattokinase and stirred evenly , homogenized for 8 minutes under the condition of 5000r / min to obtain the emulsion;

[0039] 3) Emulsion electrospray: The emulsion obtained in step 2) is electrosprayed with an electrostatic spray device, and aluminum foil is used as the receiver. The electrospray conditions are: needle 20G, voltage 10KV, emulsion flow rate 0.5ml / h, needle point to accept The distance of the aluminum foil is 8cm; the solid powder obtained after elect...

Embodiment 3

[0042] A preparation method for nattokinase microcapsules, comprising the steps of:

[0043] 1) Selection of raw materials: according to the ratio of whey protein, nattokinase and deionized water is 15g: 1.5g: 100mL, weigh whey protein, nattokinase and solvent deionized water for later use;

[0044] 2) Preparation of emulsion: according to the proportioning of the raw materials weighed in step 1), whey protein was dissolved in deionized water, and prepared into a 15% aqueous solution, stirred overnight at room temperature, then added nattokinase and stirred evenly, 10000r Homogenize for 3 minutes under the condition of / min to obtain the emulsion;

[0045]3) Emulsion electrospray: The emulsion obtained in step 2) is electrosprayed with an electrostatic spray device, and aluminum foil is used as the receiver. The electrospray conditions are: needle 21G, voltage 15KV, emulsion flow rate 1ml / h, needle tip to accept aluminum foil The distance is 12cm; the solid powder obtained af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com