A method for extracting and purifying polysaccharides from Ferulica ferulae

A purification method, the technology of ferulae ferulae, is applied in the field of extraction and purification of biological polysaccharides from ferulae ferulae, extraction and purification of biologically active polysaccharides, and extraction and purification of natural product polysaccharides. The effect of long extraction time and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

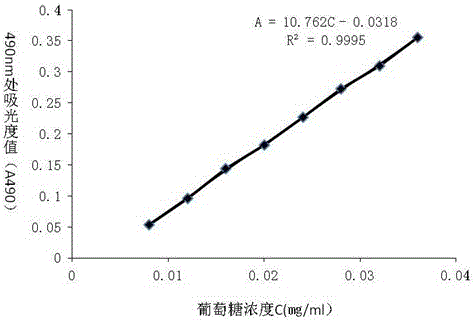

Image

Examples

Embodiment 1

[0027] Example 1: Extraction and Purification of Polysaccharides from Ferulica Ferulae

[0028] The specific preparation method steps of the extraction and purification method of the polysaccharides of ferulica ferulae are as follows:

[0029] (1) Crush and sieve the dried fruiting bodies of Ferulicum ferulae with a pulverizer, weigh 40 mesh Ferula ferulae powder and 80% ethanol according to the ratio of material to liquid 1:10—1:15 (g / ml) at 80°C Reflux for 4h, filter off ethanol, and evaporate the residue to dryness under reduced pressure.

[0030](2) Ultrasonic-microwave extraction: use the response surface optimization method to determine the extraction temperature, extraction time and solid-liquid ratio Treatment process conditions: mix the residue obtained in step (2) with water according to the solid-liquid ratio of 1:15 (g / ml) Afterwards, it was moved into an ultrasonic microwave extractor, and extracted for 15 minutes at an ultrasonic power of 50W, an extraction temp...

Embodiment 2

[0037] (1) Raw material pretreatment: cut the dried fruiting bodies of Ferulae ferulae into pieces, crush them with a pulverizer, pass through a 40-mesh sieve, weigh 10g of Ferulae ferulae powder, add 150ml of 80% ethanol to it and reflux twice at 80°C, each time 2h, ethanol was filtered off, and the residue was evaporated to dryness under reduced pressure.

[0038] (2) Ultrasonic-microwave extraction: add 150ml of water to the pretreated residue, dissolve evenly, and then transfer it to an ultrasonic microwave extractor. Extract for 15 minutes at an ultrasonic power of 70W and an extraction temperature of 70°C, and then extract the filtrate at a speed of 4000r / min. , refrigerated and centrifuged for 15min, after collecting the supernatant, the residue was subjected to ultrasonic microwave extraction again, and the two supernatants were combined, and then 4 times the volume of 95% ethanol was added to the supernatant, so that the volume percentage concentration of ethanol in th...

Embodiment 3

[0043] Embodiment three: comparative example 1

[0044] Extraction of polysaccharides by hot water leaching: cut the dried fruiting bodies of Ferula ferulae into pieces, crush them with a pulverizer, and pass through a 40-mesh sieve. After 2h, ethanol was filtered off, and the residue was evaporated to dryness under reduced pressure. Add 150ml of water to the pretreated residue, dissolve evenly, reflux twice in a water bath at 80°C for 2 hours each time, combine the two extracts, and then concentrate in vacuum with a vacuum degree of -0.07~-0.08MPa and a temperature of ≤70 ℃). Freeze and dry to obtain the crude polysaccharide of feruli mushroom in solid state.

[0045] Sevag method for deproteinization: obtain the solution of crude polysaccharide solid solution, and Sevag reagent (V chloroform: V n-butanol = 4:1) according to the volume ratio of 5:1, shake 3 times for 15 minutes each time, refrigerate centrifuge at 4000r After centrifuging for 15 minutes at a speed of 1 / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com