Novel stamping equipment used for motor processing

A stamping equipment and a new technology, applied in the field of stamping equipment for new motor processing, can solve the problems of unfavorable motor processing enterprises, such as saving production costs, high production costs, and complex structures, and achieve simple structure, low production costs, and simple transmission structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

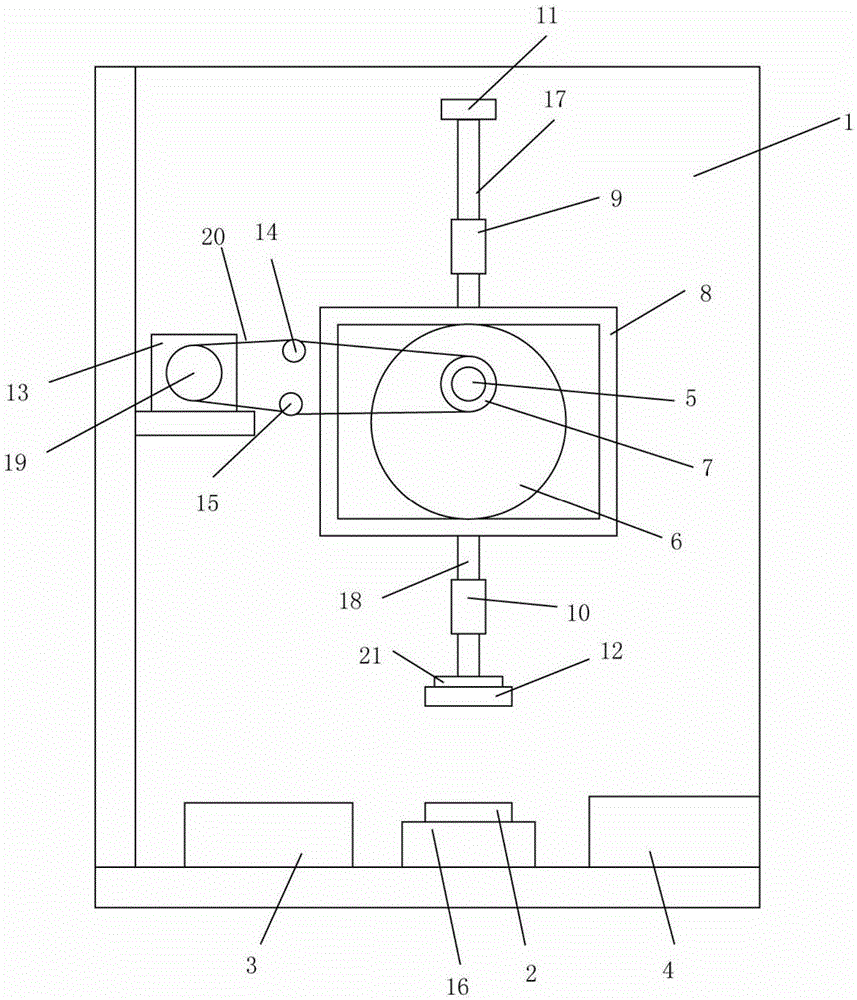

[0020] Such as figure 1 As shown, a new type of stamping equipment for motor processing includes a frame 1, a lower mold 2, a raw material tank 3, a receiving tank 4, a rotating rod 5, an eccentric wheel 6, a driven wheel 7, a frame body 8, and an upper fixing sleeve 9 , the lower fixed sleeve 10, the limit plate 11, the upper mold 12, the motor 13, the rising tensioner 14, the lower tensioner 15, the bottom of the frame 1 is equipped with a lower mold seat 16, and the lower mold 2 is installed on the lower mold seat 16 Above, the raw material chute 3 is installed on the frame 1 and it is located on one side of the lower mold 2, the receiving trough 4 is installed on the frame 1 and it is located on the other side of the lower mold 2, and the rotating rod 5 is installed on the frame 1 Above, the wheel shaft of the eccentric wheel 6 is installed on the rotating rod 5, the driven wheel 7 is installed on the rotating rod 5, the frame body 8 is arranged outside the eccentric wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com