Composite material rotary fiber placement device and use method

A technology of composite material and wire laying, which is applied in the field of composite material forming auxiliary equipment, can solve the problems that the forming mold cannot be designed as a rotary structure, is not a rotary body, and has high manufacturing costs, so as to save curing space, increase utilization rate, and save molds The effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

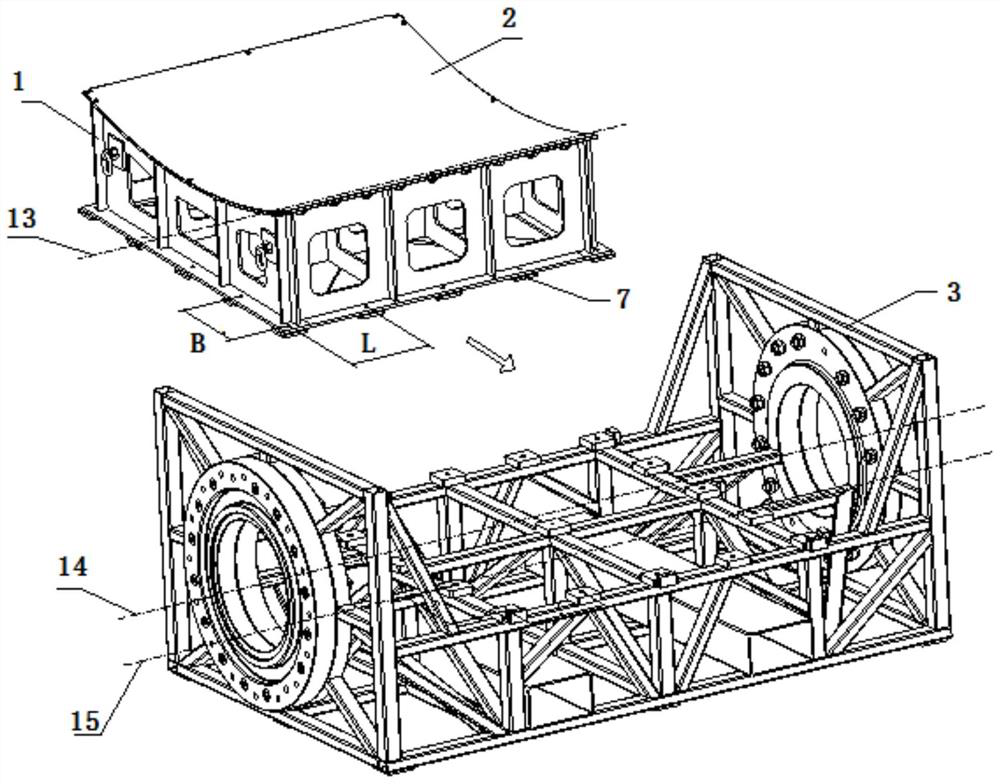

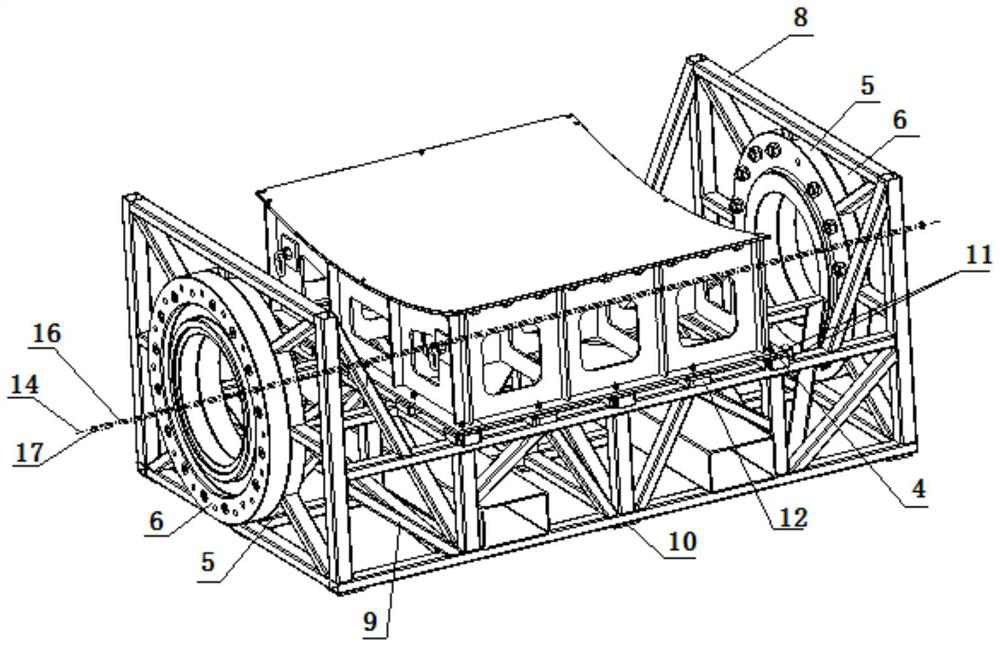

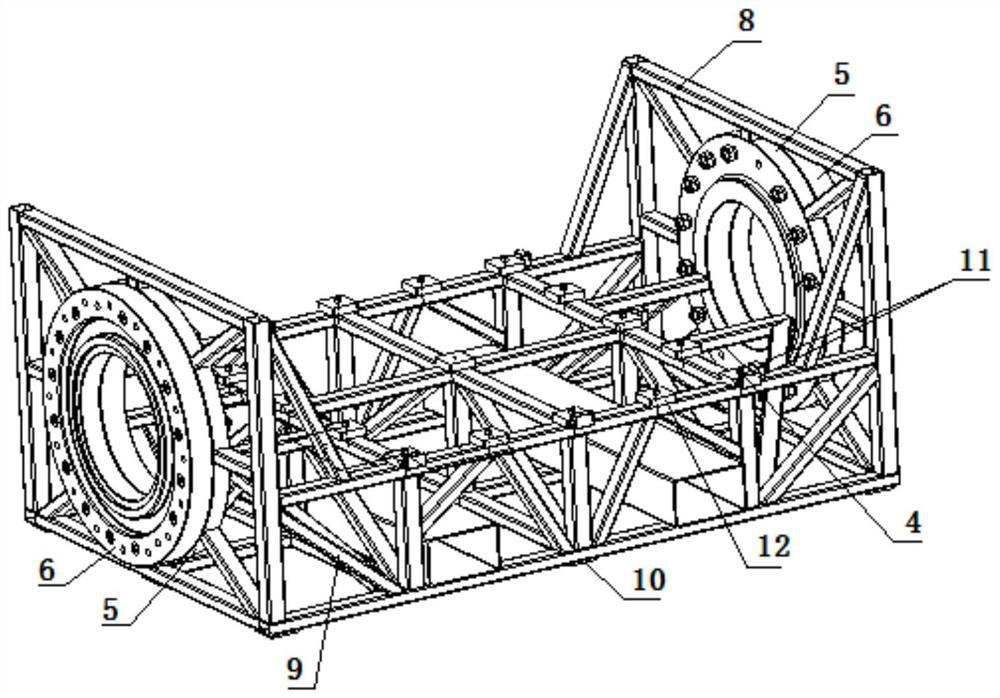

[0029] A composite material rotary laying device, comprising a ∪-shaped bottom frame 3, an adapter flange 5, and a flange 6. Two concentric transfer flanges 5 are fixed on both ends of the ∪-shaped bottom frame 3; two flanges 6 are respectively installed on the outside of the two transfer flanges 5; the ∪-shaped bottom frame 3 is provided with a support plane , the side of the support plane is provided with an initial positioning block 11 and fastener screws 4; the molding die 1 is placed on the support plane and fastened in the ∪-shaped bottom frame 3∪-shaped, forming an integral mold with two flanges After the disk 6 is tightly connected with the flange of the five-coordinate wire laying machine, the overall mold is driven up and down and rotated by the flange of the five-coordinate wire laying machine to complete the wire laying. The adapter flange 5 is provided with radial threaded holes and pin holes, and these threaded holes, pin holes are concentric with the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com