Machining method of front connecting seat of five-degree-of-freedom steering mechanism and front connecting seat

A steering mechanism and processing method technology, applied in the field of connecting seat and connecting seat processing, can solve the problems of high geometrical tolerance, high precision, deformation accuracy, etc., and achieve the effect of ensuring the geometrical tolerance and dimensional accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

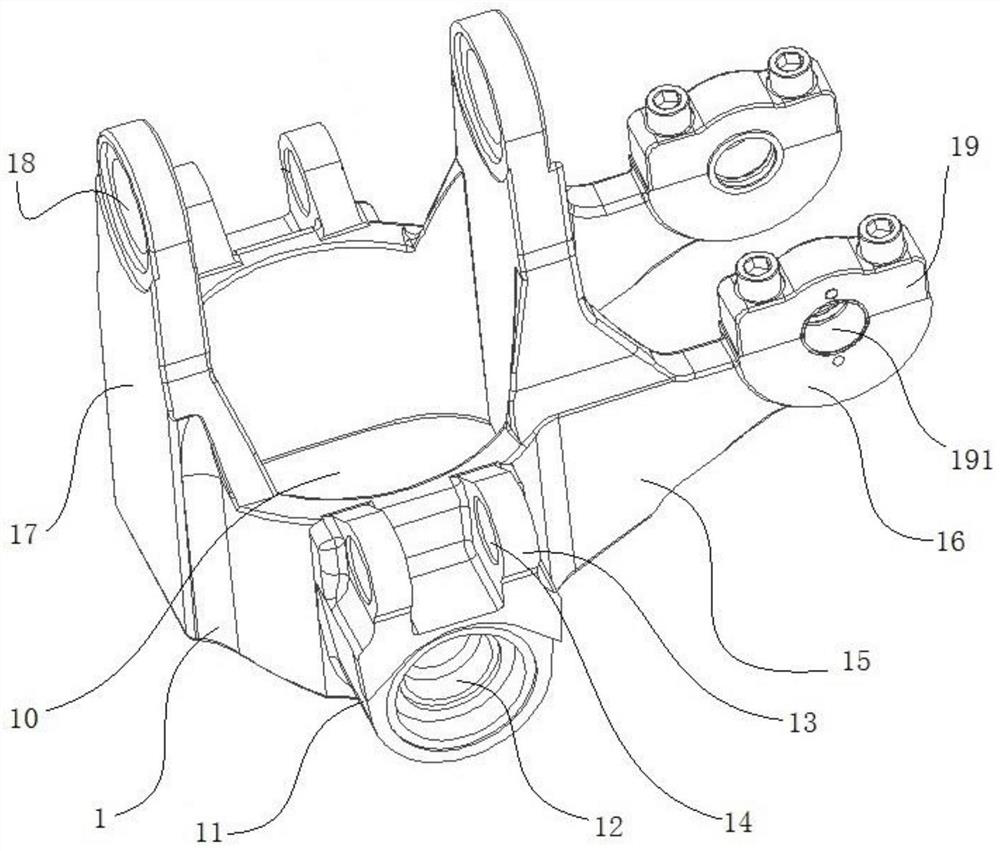

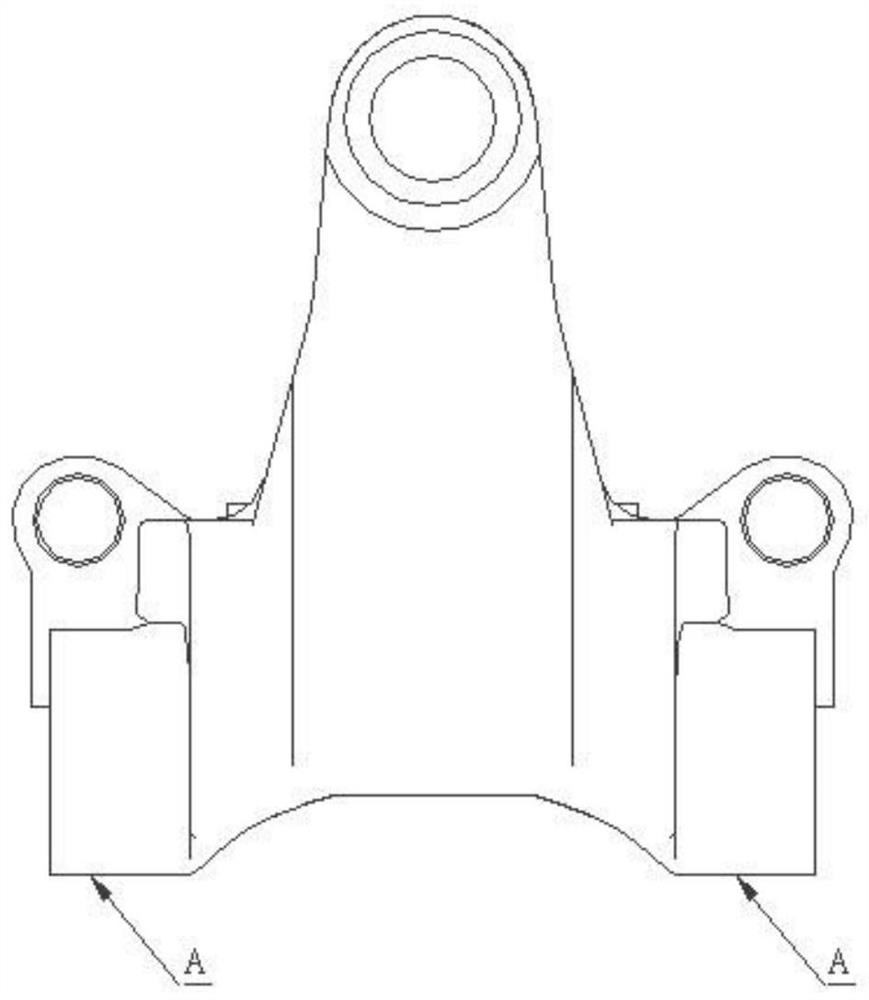

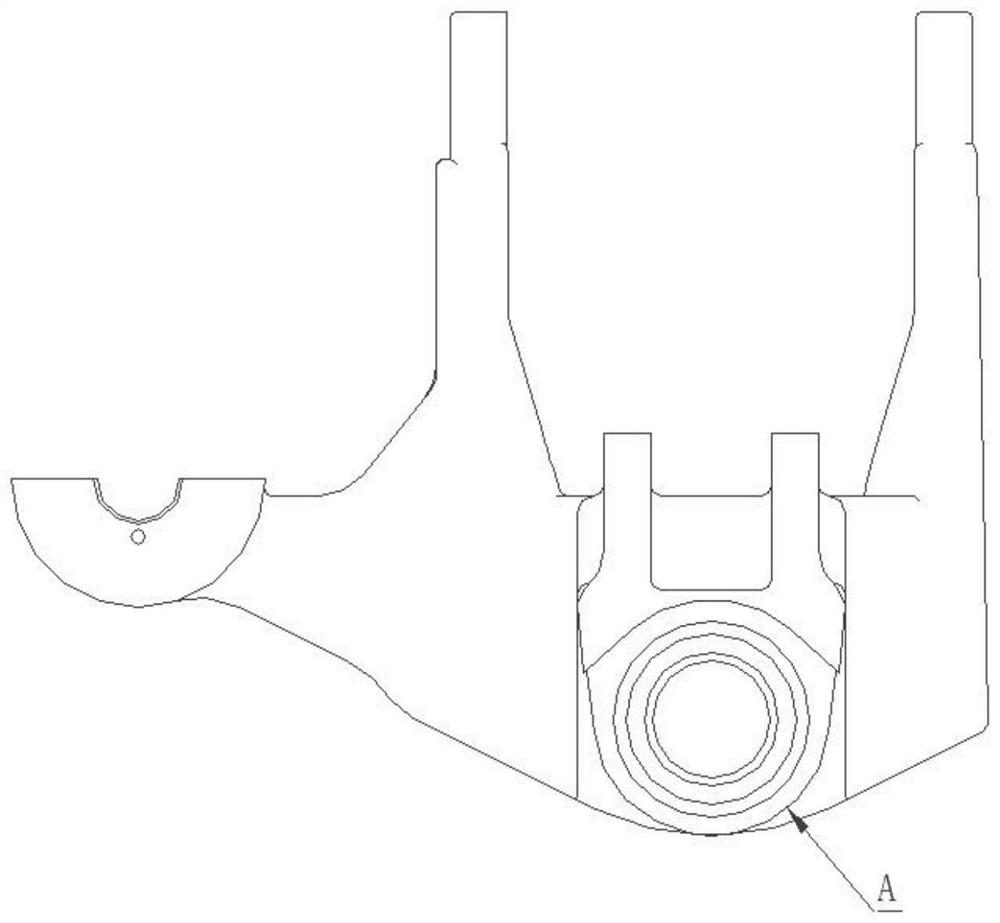

[0037] Such as Figures 2 to 12 shown.

[0038] A method for processing the front connecting seat of a five-degree-of-freedom steering mechanism of the present invention includes two steps: S1 marking positioning and S2 processing and forming by using the positioning fixture 2 to clamp and position.

[0039] S1 marking positioning is to find out the position between each hole to ensure the accuracy of processing, S2 processing and forming is to use the positioning fixture 2 to clamp the front connecting seat once to complete the processing of the holes at each position.

[0040] S1 marking positioning includes the following steps in sequence:

[0041] S1-1: If figure 2 and image 3 As shown, the outer sides of the two arcs of the first cantilever 11 of the blank are ground, and the burrs and sand sticking due to casting are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com