Hybrid power system of engine integrated motor

A technology of a hybrid power system and an integrated motor, which is applied in the directions of hybrid power vehicles, electromechanical devices, power devices, etc., can solve the problems of difficult motor assembly, large radial runout, and large space occupation, and achieves simple and convenient installation and radial runout. Small, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

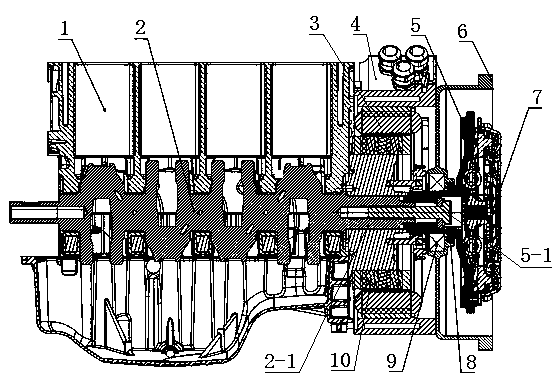

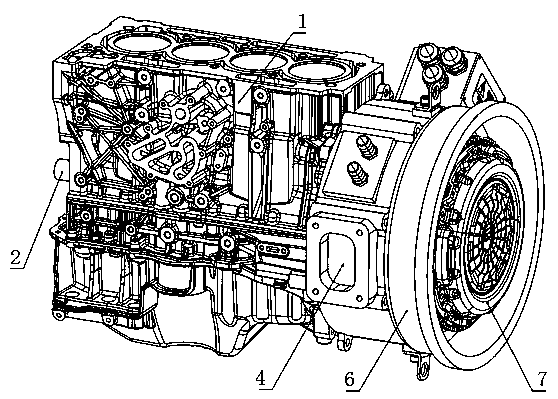

[0017] Such as figure 1 , figure 2 A hybrid power system with an engine integrated motor is shown, including a motor connected to the engine, a flywheel assembly and a clutch 7, and the motor has a motor housing 4, a motor stator 3, a motor rotor 10 and a motor that are sequentially arranged from outside to inside Shaft 2-1, the motor shaft 2-1 is integrally formed with the crankshaft 2 of the engine, and the motor housing 4 is integrally formed with the cylinder block 1 of the engine. The flywheel assembly has a flywheel 5 and a connecting shaft 5-1, the connecting shaft 5-1 and the flywheel 5 are of an integrated structure, the connecting shaft 5-1 is coaxially fixedly connected with the motor shaft 2-1, and the connecting shaft 5-1 has a 2-1 socketed connection hole, the outer end of the connection hole is provided with a limiter, the bolt connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com