Diesel engine frame air cylinder hole boring device

A technology for cylinder bores and diesel engines, applied in the direction of boring/drilling, drilling/drilling equipment, boring bars, etc., can solve problems affecting the normal operation of diesel engines, affecting the assembly accuracy of cylinder sets, and affecting piston movement, etc., to achieve reduction The effect of processing cost, convenient detection and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

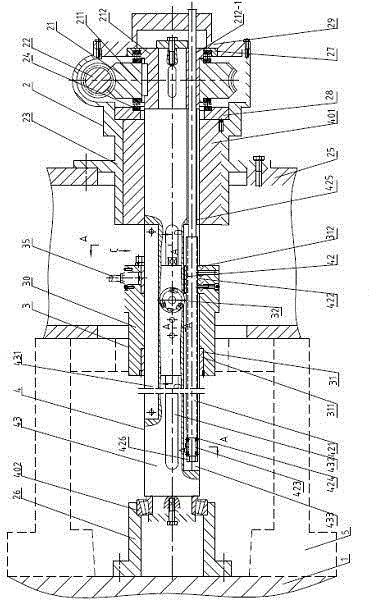

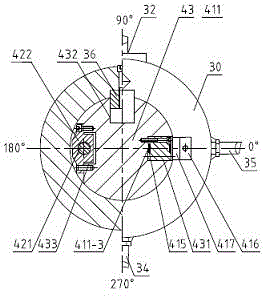

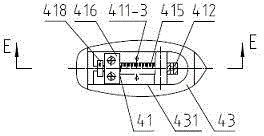

[0021] Such as figure 1 As shown, the present invention includes a boring bar transmission mechanism 2, a cutter body mechanism 3, and a boring bar mechanism 4. The boring bar transmission mechanism 2 is arranged on one end of a boring bar 43, and includes a worm wheel 21, a worm screw 22, a worm gear box 23, and a pair of supports Bearing 24, positioning frame 25, positioning seat 26. The worm wheel 21 of this embodiment is formed by fixedly connecting the wheel rim 211 and the wheel core 212. The wheel core 212 and the end of the boring bar 43 are fixedly connected by a flat key. 28. On the small retaining ring 27, the large retaining ring 28 and the small retaining ring 27 are respectively installed in the step holes on both sides of the worm gear casing 23, and the worm gear casing cover 29 is fastened on the outer end of the worm gear casing 23 by screws. The wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com