One-time forming processing device of square pipe hoop

A technology of forming and moulding, applied in forming tools, feeding devices, positioning devices, etc., can solve the problems of many processes, affecting the overall aesthetics of iron art, inaccurate positioning, etc. The workpiece is convenient and fast, and the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

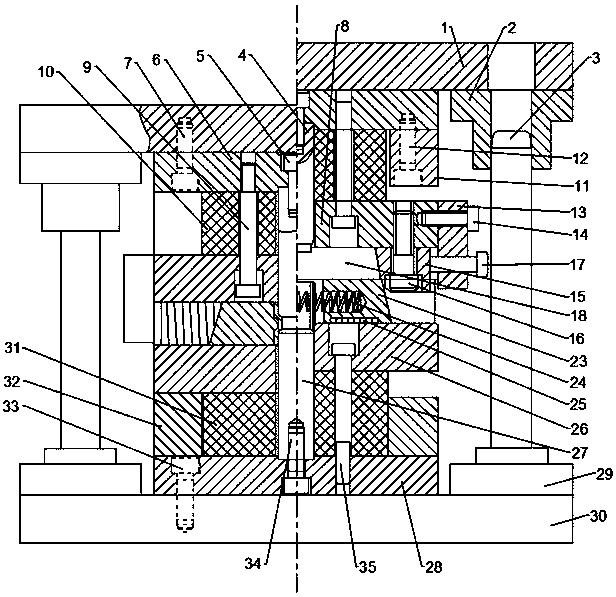

[0026] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

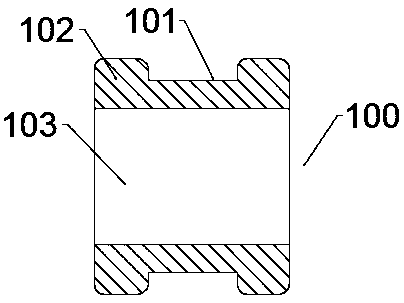

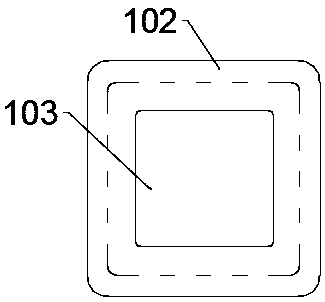

[0027] The shape of the square tube hoop is as attached Figure 1-2 As shown, it includes a square tube hoop body 100, a square through hole 103 is arranged in the square tube hoop body 100, and two protruding hoop bodies 102 are respectively provided at both ends of the side wall 101 of the square tube hoop body 100.

[0028] In order to ensure the quality of the product, it is first necessary to ensure that the blank can meet the specified requirements. When producing blanks, the blanks are accurately blanked by the band sawing machine, the length of the blanks, the shape of the cross section, the parallelism of the two sections of the blanks and the perpendicularity to the square hole are controlled. The relative consistency of the billet is the basis for ensuring product quality. The present invention processes the above-mentioned b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com