A processing method for a large thin-walled oblique eccentric shaft sleeve of a gyratory crusher

A technology of gyratory crushers and eccentric shaft sleeves, which is applied in the field of mechanical manufacturing and processing, can solve the problems of easy deformation of clamping, skewed positioning of inner holes, inaccuracy, etc., and achieve the effect of solving clamping problems and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

[0039] The embodiment takes the main shaft bushing for the eccentric mechanism of a large crusher as an example; the characteristics and technical requirements of the eccentric bushing are as follows:

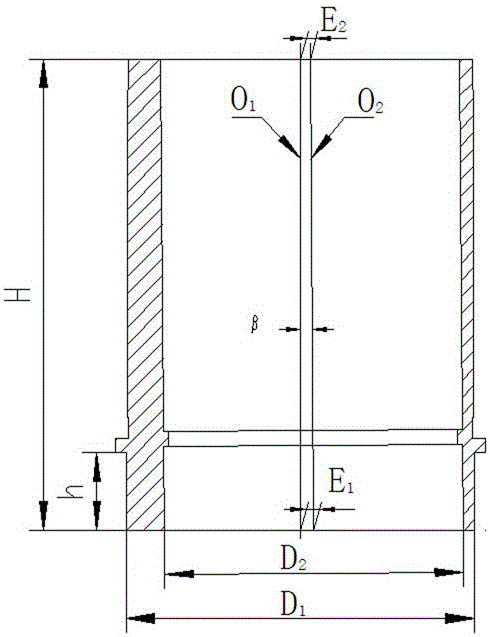

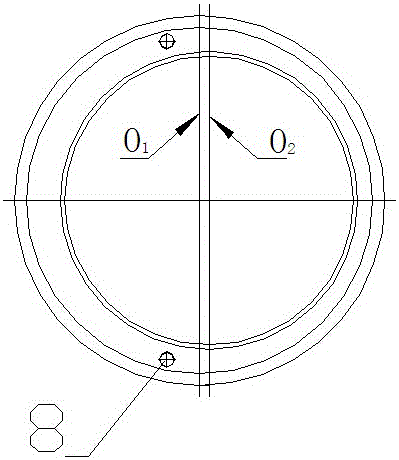

[0040] Eccentric shaft sleeve: weight 4264kg, material 42CrMo, external dimensions are about Φ1190×Φ850×1730, and the overall size of the forging blank is about Φ1240×Φ630×1900. The main technical requirements for processing: outer circle roughness Ra0.8, inner hole roughness Ra1.6, eccentricities at both ends are 57.85±0.05 and 41.48±0.05 respectively, the maximum wall thickness difference is 115mm, and the amount of blank material removal is very large.

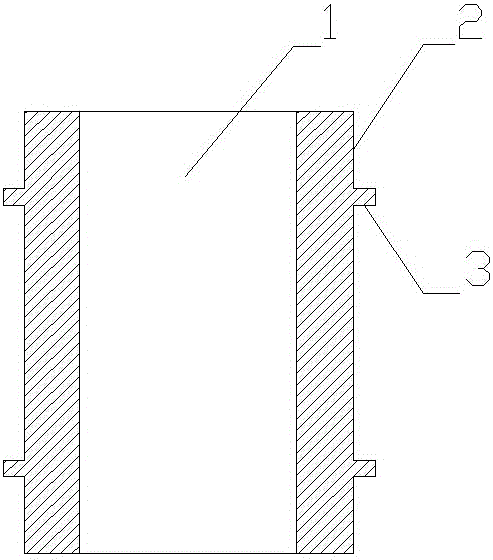

[0041] The above-mentioned eccentric shaft sleeve is processed by the processing method of a large thin-walled oblique eccentric shaft sleeve of a gyratory crusher according to the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com