Clamping tool for crane boom head and boom tail machining

A technology for clamping tooling and cranes, used in metal processing equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of multi-manpower, low production efficiency, unstable welding quality, etc., to improve the degree of automation, improve production efficiency, save money human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

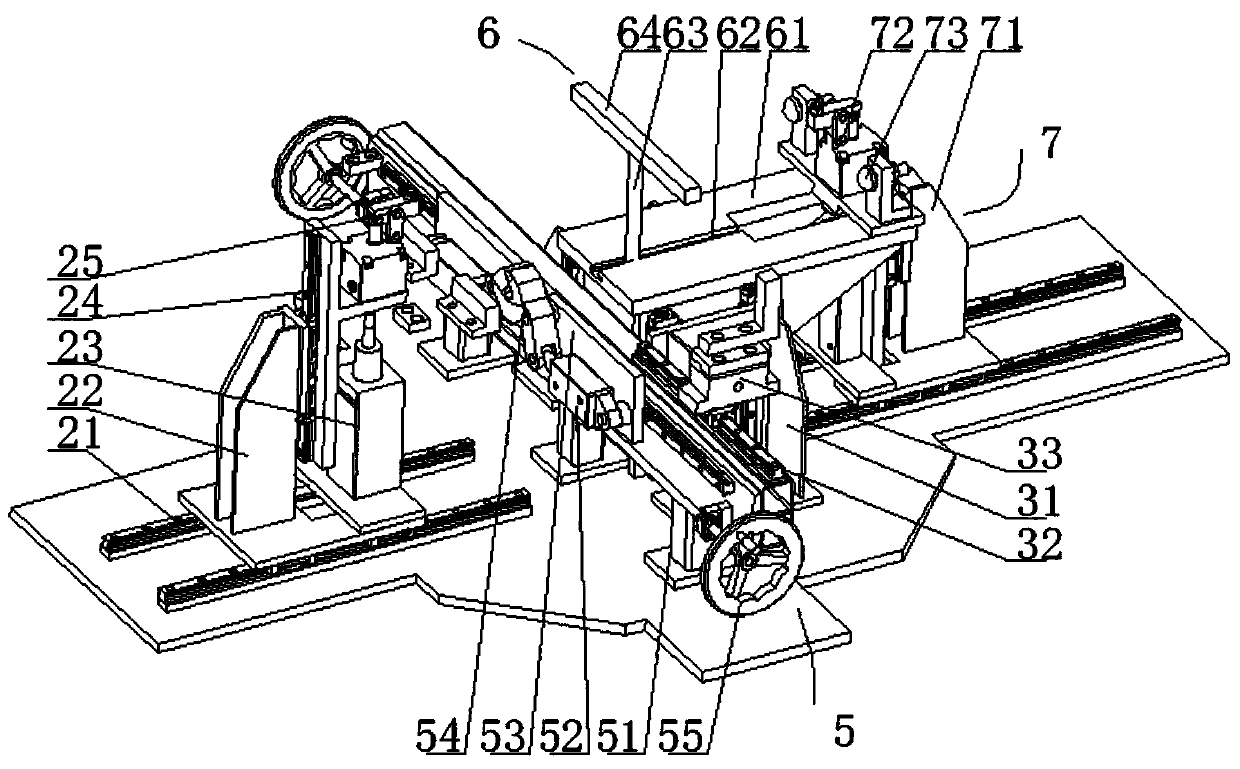

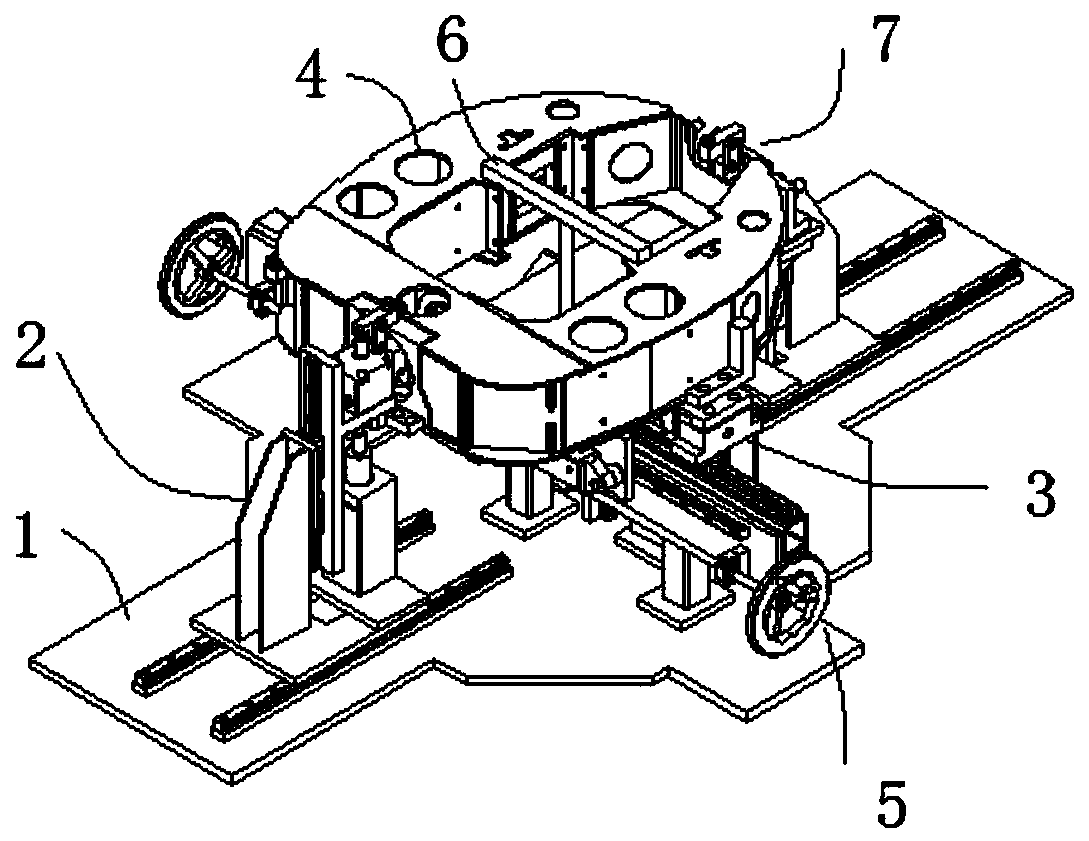

[0029] like figure 2 As shown, the clamping tooling for the processing of the crane arm head and arm tail designed by the present invention includes a tooling base plate 1 and a front clamping mechanism 2 installed on the tooling base plate, a middle centering mechanism 3, a workpiece 4, and a bottom pressing adjustment mechanism 5 , middle pressing bar 6 and rear end clamping mechanism 7, described front end clamping mechanism 2 and rear end clamping mechanism 7 fix the front end and the rear end of workpiece 4, and described middle part centering mechanism 3 adjusts workpiece 4 in tooling The horizontal position on the bottom plate 1, the bottom pressing adjustment mechanism 5 fixes the workpiece 4 through the opening at the bottom of the workpiece, the middle pressing rod 6 realizes the fixing of the upper end surface of the workpiece 4 by pressing down, and the front end clamping mechanism 2. The middle centering mechanism 3, the bottom pressing adjustment mechanism 5, th...

Embodiment 2

[0041] like figure 1 and 2 As shown, the clamping tooling for the processing of the crane arm head and arm tail designed by the present invention includes a tooling base plate 1 and a front clamping mechanism 2 installed on the tooling base plate 1, a middle centering mechanism 3, a workpiece 4, and a bottom pressing adjustment mechanism 5. The central pressing rod 6 and the rear end clamping mechanism 7, the front end clamping mechanism 2 and the rear end clamping mechanism 7 fix the front end and the rear end of the workpiece, and the middle centering mechanism 3 adjusts the workpiece on the tooling base plate 1 The horizontal position of the horizontal position, the middle pressing rod 6 and the bottom adjustment structure are set as reserved installation positions, which are not practically used. Through the setting of this structure, the front clamping mechanism, the middle centering mechanism and the rear clamping mechanism The cooperation between them realizes the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com