Reference temperature T0 test method for irradiated RPV steel 0.5T-CT sample

A 0.5T-CT, reference temperature technology, applied in the field of post-irradiation inspection, to solve the problem of clamping, avoid radiation exposure, and meet the effects of radiation protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

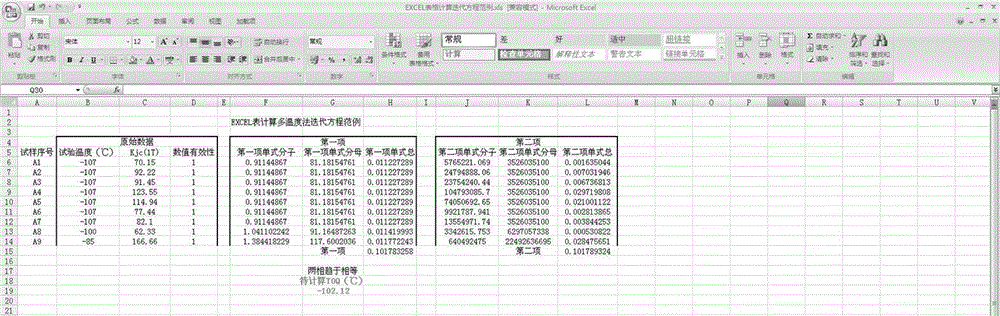

Method used

Image

Examples

Embodiment

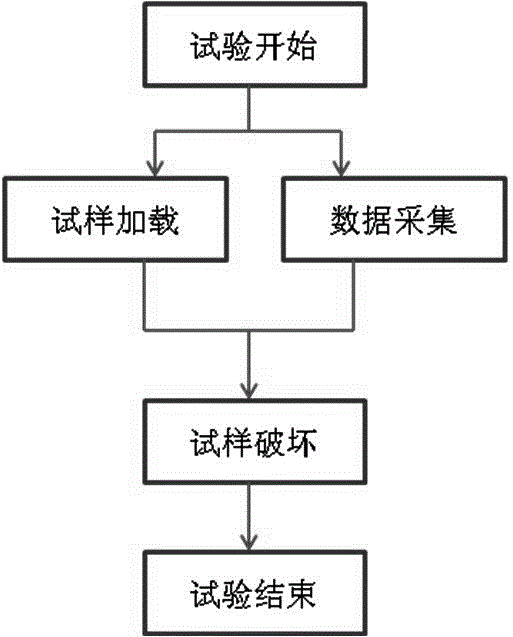

[0061] A reference temperature T of RPV steel 0.5T-CT sample after irradiation 0 The test method includes the following steps:

[0062] S1. Check the test system and samples before the test, identify and record the sample number,

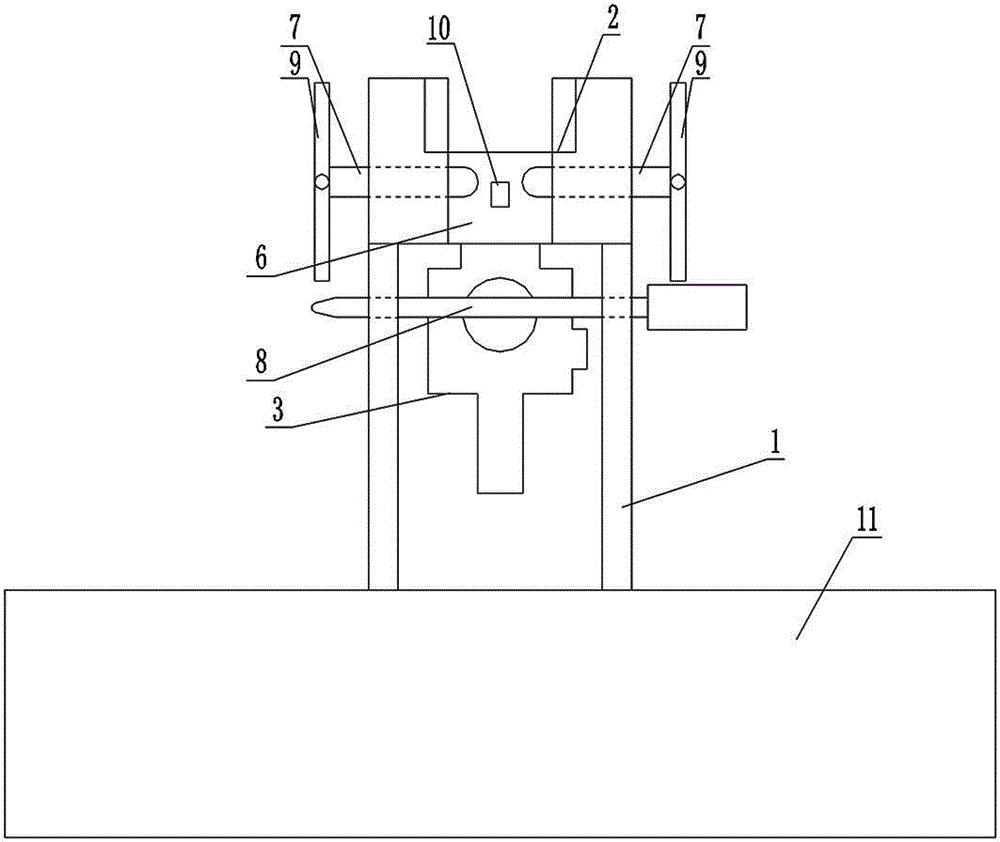

[0063] S2. Through the manipulator, the COD gauge auxiliary loading device is used to complete the loading of the COD gauge 4 and the sample 12, which includes the following sub-steps:

[0064] S21. Put the COD gauge 4 into the COD gauge loading slot 3 of the COD gauge auxiliary loading device through the manipulator;

[0065] S22. Screw in the screw rod 7 step by step from the left and right sides of the manipulator, and press the gauge arm 5 of the COD gauge 4 close to the limit position, so that the distance between the two gauge arms 5 is smaller than the bayonet width of the sample;

[0066] S23. Load the sample 12 into the sample loading slot 2 of the COD gauge auxiliary clamping device through the manipulator. In order to improve the stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com