Low-temperature sterilization device for food production

A sterilization device, low-temperature technology, applied in the fields of food preservation, application, food science, etc., can solve the problems of radiation outflow, product storage, and increase the labor input of staff, so as to avoid radiation outflow, improve the sterilization effect, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

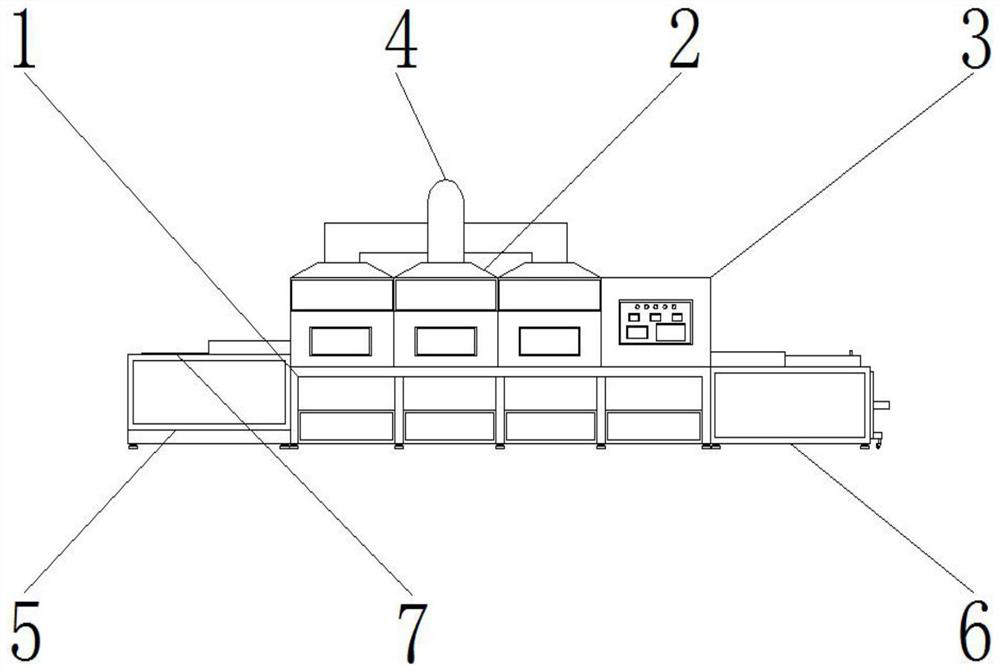

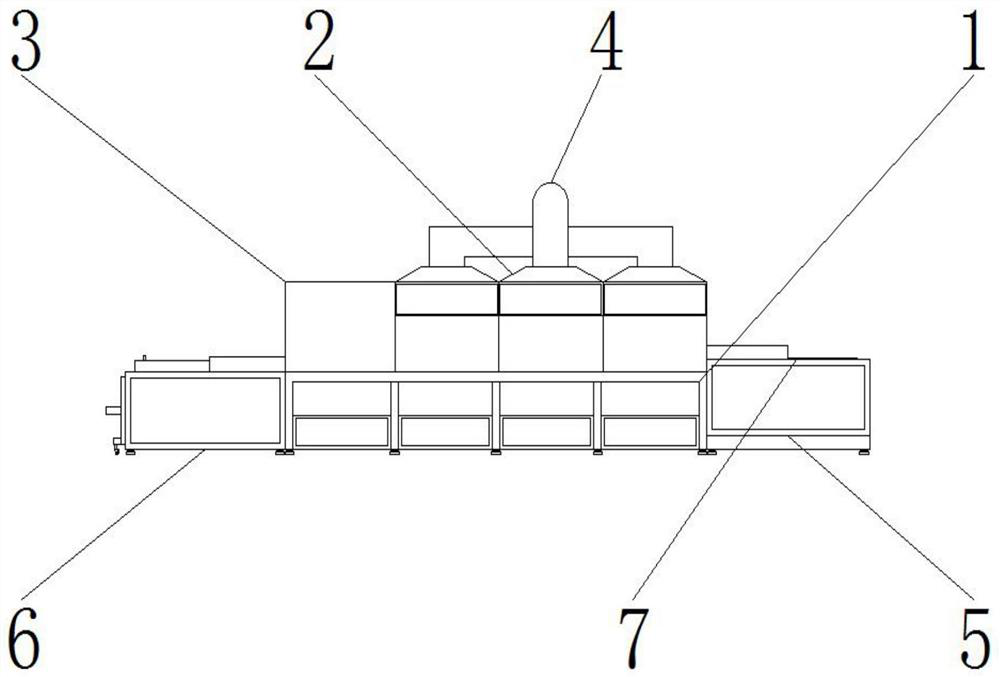

[0027] Such as figure 1 As shown, a low-temperature sterilization device for food production includes a workbench 1, a sterilization box 2 and a control cabinet 3 are arranged on the outer surface of the upper end of the workbench 1, and the control cabinet 3 is located on one side of the sterilization box 2. The outer surface of the upper end of the sterilization box 2 is provided with an exhaust device 4, the outer surface of one side of the workbench 1 is provided with a feeding cabinet 5, and the outer surface of the other side of the workbench 1 is provided with a storage device 6, and the outer surface of the workbench 1 is provided with a storage device 6. The inner surfaces of both sides are provided with dislocation transmission devices 7, the material storage device 6 includes a material storage outer shell 601, a protective plate 602, a movable cover 603, a handle 604, a material storage box 605 and a moving wheel 606, and the dislocation transmission device 7 includ...

Embodiment 2

[0029] On the basis of Example 1, such as figure 1 , 2 , 6, the outer surface of the upper end of the material storage shell 601 is provided with a protective plate 602 and a movable cover 603, the movable cover 603 is located below the protective plate 602, and the outer surface of the upper end of the movable cover 603 is provided with a handle 604, the storage The inner surface of the lower end of the material housing body 601 is provided with a material storage box 605, and one side of the outer surface of the material storage box 605 is provided with a moving wheel 606, which can protect the discharge port, avoid radiation transmission, and can simultaneously products for storage.

Embodiment 3

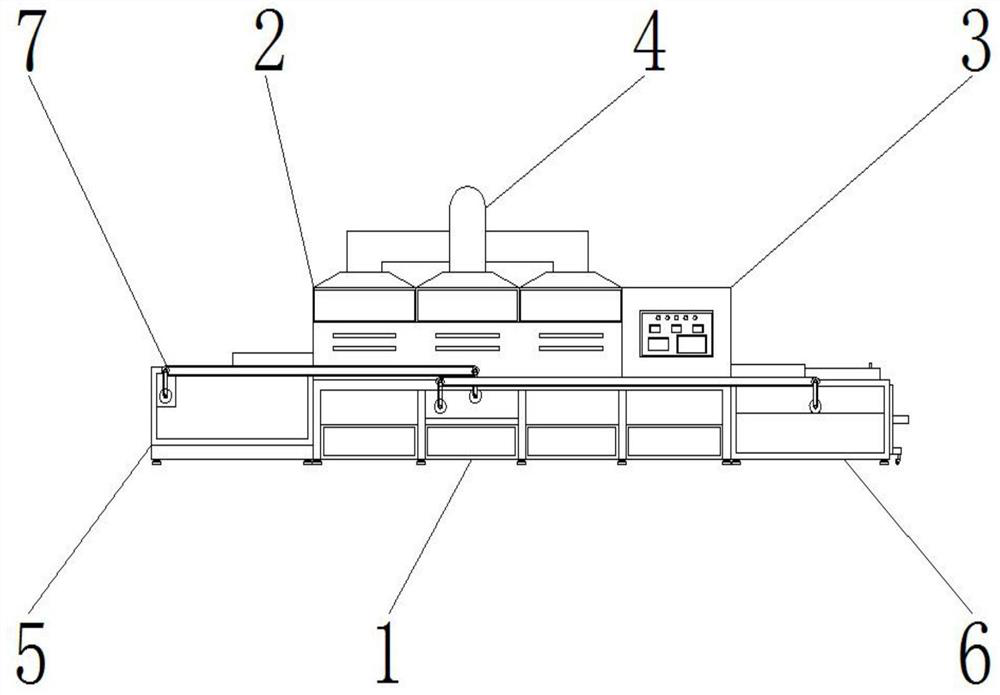

[0031] On the basis of Example 1, such as image 3 , 4 , 5, the bottom of the upper conveyor belt 701 is provided with a lower conveyor belt 702, the inner walls of the upper conveyor belt 701 and the lower conveyor belt 702 are all provided with a driving drum 703, and the outer surface of one end of the driving drum 703 is provided with a transmission chain 704, and the inner wall of the transmission chain 704 A synchronous driving device 705 is provided, and the number of the lower conveyor belt 702, the driving roller 703, the transmission chain 704 and the synchronous driving device 705 are all four groups, which can adjust the position and posture of the product during product sterilization to improve the sterilization effect of food .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com