A method for improving the machining accuracy of aluminum alloy thin-walled parts used for gyro frames

A technology for machining precision and thin-walled parts, which is applied in the field of improving the machining accuracy of aluminum alloy thin-walled parts used for gyroscope frames, can solve the problems of high precision, inability to guarantee machining accuracy, and poor machining of aluminum alloy thin-walled parts, and achieve Improve cutting performance, save raw material cost, and relieve stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for improving the machining accuracy of an aluminum alloy thin-walled part used for a gyroscope frame, the specific steps are as follows:

[0030] Step 1) Rough machining of the part body;

[0031] Step 2) Perform the first heat treatment on the part body; the first heat treatment adopts solution aging heat treatment;

[0032] Step 3) Semi-finishing the part body;

[0033] Step 4) Carry out the second heat treatment on the part body; the second heat treatment adopts the intermediate heat treatment of two cycles of cold and heat;

[0034] Step 5) Connect the process reinforcing rib to the pressing surface of the part body;

[0035] Step 6) Finishing before surface finishing;

[0036] Step 7) Carry out the third heat treatment on the part body, and the third heat treatment adopts solution aging heat treatment;

[0037] Step 8) Finishing of final finished dimensions after surface finishing;

[0038] Step 9) Remove process ribs.

Embodiment 2

[0040] A method for improving the machining accuracy of an aluminum alloy thin-walled part used for a gyroscope frame, the specific steps are as follows:

[0041] Step 1) Rough machining of the part body; 1) Turning of the upper part, lower part, positioning outer circle, and positioning end face of the part body 1; 2) Milling of the machining center to complete the bearing fitting hole, bearing positioning surface, connecting hole, and torque motor The rough machining of the size of the hole and the positioning surface of the torque motor removes a large machining allowance.

[0042] Step 2) Carry out the first heat treatment on the part body; the first heat treatment adopts solution aging heat treatment; first clean the surface of the part body to make the surface free of chips, and then heat the part body in a constant temperature box to a temperature of 90 °C and keep it warm After 3 h, it was then air cooled to room temperature.

[0043] Step 3) Semi-finishing the part b...

Embodiment 3

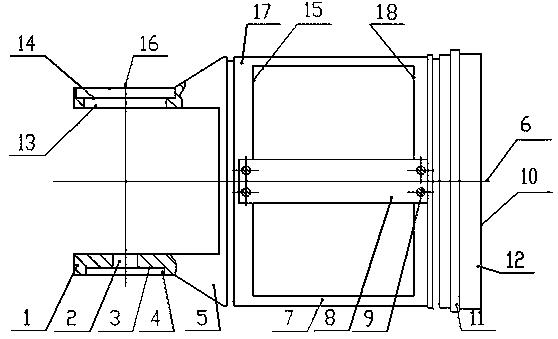

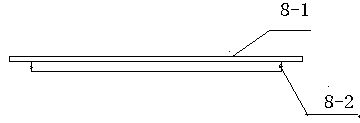

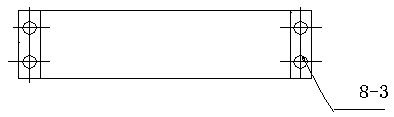

[0051] Such as figure 1 As shown, the aluminum alloy thin-walled parts used for the gyro frame are prior art, and it includes a part body 1, and the described part body at least includes: a bearing fitting hole 2, a torque motor hole 13, a screw 9, a positioning outer circle 12, The positioning end surface 10, the bearing matching hole 2 is smaller than the torque motor hole 13, and is distributed on the upper part 5 of the part body 1, coaxial with the a-axis 16, and symmetrical with the b-axis 6, the positioning outer circle 12, and the positioning end surface 10 are on the processing body 1 The lower part 11 , the upper part 5 of the part body 1 and the lower part 11 of the part body 1 are connected by ribs 7 and by screws 9 .

[0052] The specific steps of the method for improving the processing accuracy of the aluminum alloy thin-walled parts used for the gyro frame of the present invention are as follows: step 1) rough machining the part body; 1) upper part 5, lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com