Valve grinding method

A valve and grinding technology, which is applied in the direction of grinding driving device, grinding machine parts, grinding/polishing equipment, etc., can solve the problems affecting the service life of the valve, fatigue, erosion, parking accidents, etc., and achieve the extension of early Effect of wear cycle, reduction of processing stress, total time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] A valve grinding method, comprising the steps of:

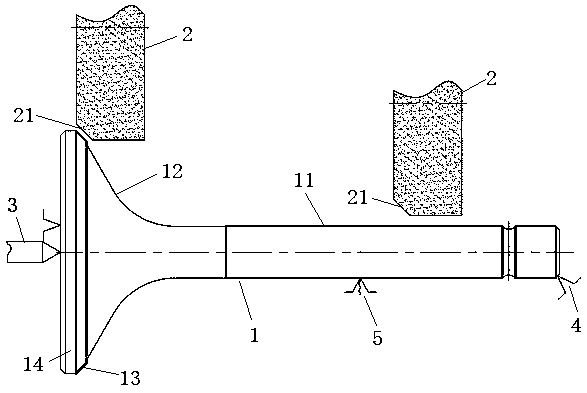

[0019] S1, see figure 1 , the valve 1 includes a valve stem 11 and a valve neck connected to the valve stem 11, the bottom end of the valve neck is connected to the valve disk 14 through the valve seal, and the valve cone surface is composed of the interconnected valve neck transition cone surface 12 and The valve sealing cone surface 13 consists of two parts. Position the valve 1 through the chamfering of the free end of the valve disc 14 and the free end of the valve stem 11, and fix it on the main shaft of the grinder by clamping the top 1 3 and the top 2 4, and install the top 1 3 and the top 2 4 on the head of the grinding machine table respectively rack and tailstock.

[0020] S2, start the grinding machine, the spindle drives the valve 1 to rotate around the valve axis.

[0021] S3, adjust the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com