Hydraulic integrated oil cylinder barrel and machining method thereof

A technology of hydraulic integration and processing method, which is applied in the direction of fluid pressure actuating device, using stable tension/pressure testing material strength, measuring device, etc. To meet the requirements, cylindricity influence, performance degradation and other issues, to achieve the effect of simple alignment and positioning and clamping, ensuring the requirements of various geometric tolerances, and solving the bottleneck of the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

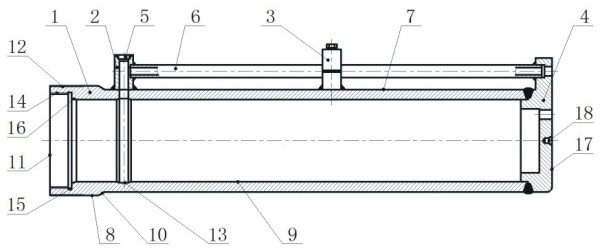

[0025] The present invention will be further described below according to the embodiments provided by the accompanying drawings.

[0026] Step 1, when the workpiece is blanked and roughed, after the cylinder 1 blank is blanked, the cylinder 1 blank is subjected to rough turning of the outer circle and both ends of the cylinder; the cylinder 1 blank is made of steel pipe, and Leave a machining allowance, the machining allowance of each outer circle of the cylinder 1 blank is not less than 5mm, the machining allowance of the inner hole 9 is not less than 5mm, and the total length of the cylinder 1 blank is not less than 15mm; on the lathe, the inner hole 9 Clamp the blank of the cylinder 1 for the positioning reference, and clamp it with two tops, use the three-jaw chuck and the top of the tailstock of the lathe to respectively press the two ends of the inner hole 9, and the rough turning of the cylinder 1 blank reaches the outer circle. See the light; take the outer circle of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com