A linear motion device used in a charged environment

A linear motion and environmental technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of high processing difficulty, low production cost, low processing difficulty, etc., to reduce processing cost, reduce damage, reduce The effect of difficulty in production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

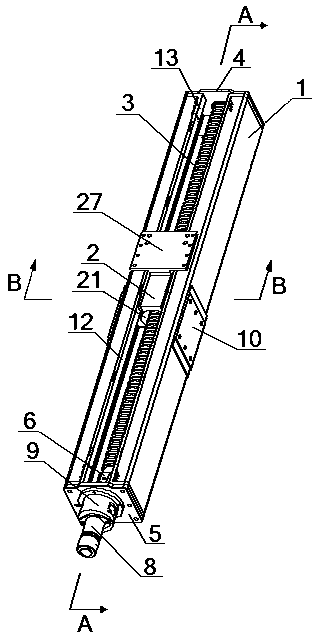

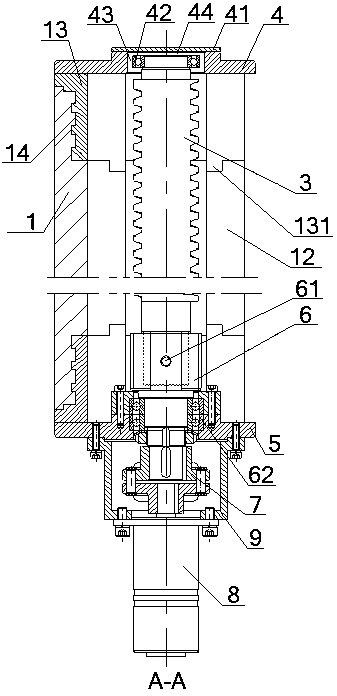

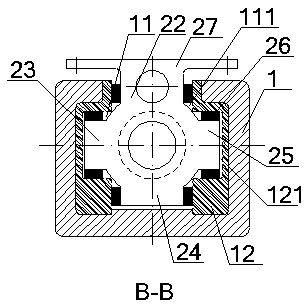

[0060] see figure 1 - Figure 7 , a linear motion device used in a live environment, the device includes a guide device 1, a slider 2, a screw 3, a No. 1 end cover 4, a No. 2 end cover 5, a connecting shaft 6, a coupling 7 and a drive motor 8. The manufacturing material of the guide device 1 is glass fiber reinforced epoxy resin-based composite material, the manufacturing material of the screw rod 3 is insulating material, the guide device 1 is a hollow structure with openings at both ends, and the outside of the guide device 1 passes through the clamping device 10 is connected with external equipment, and the inside of the guide device 1 is provided with a convex chute 11, and the inner wall of the chute 11 is symmetrically provided with nylon liners 12 on the left and right sides, and the inner wall of the nylon liner 12 includes 5 sequentially The guide surface 121 is vertically connected to form a several-shaped structure. The slider 2 is a cross-shaped structure, includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com