Bearing sealing ring

A bearing sealing and sealing lip technology, which is applied in the field of bearing sealing rings with tapered holes on the spherical surface, can solve the problem of difficult control of the interference between the sealing lip and the bearing ring, the weakening of the elastic deformation capacity of the bearing sealing ring, and the increase in the assembly of the bearing sealing ring Difficulty and other issues, to achieve the effect of convenient machine tool pressing, prolonging service life and increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

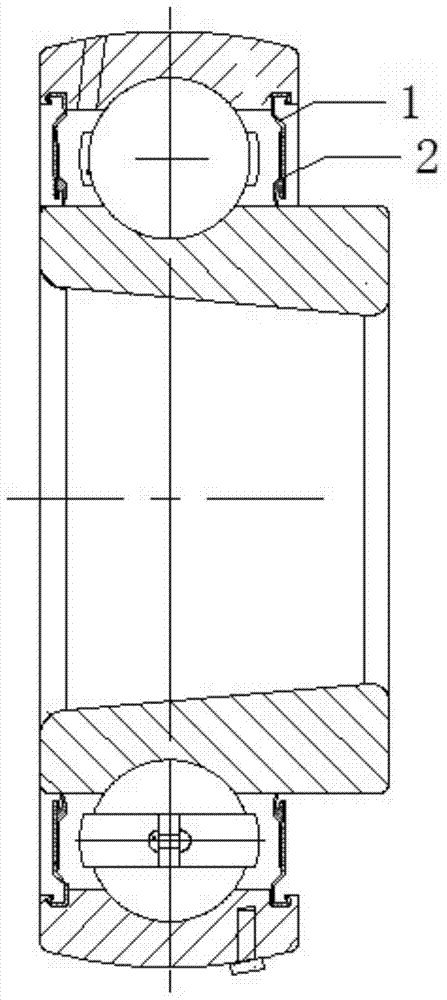

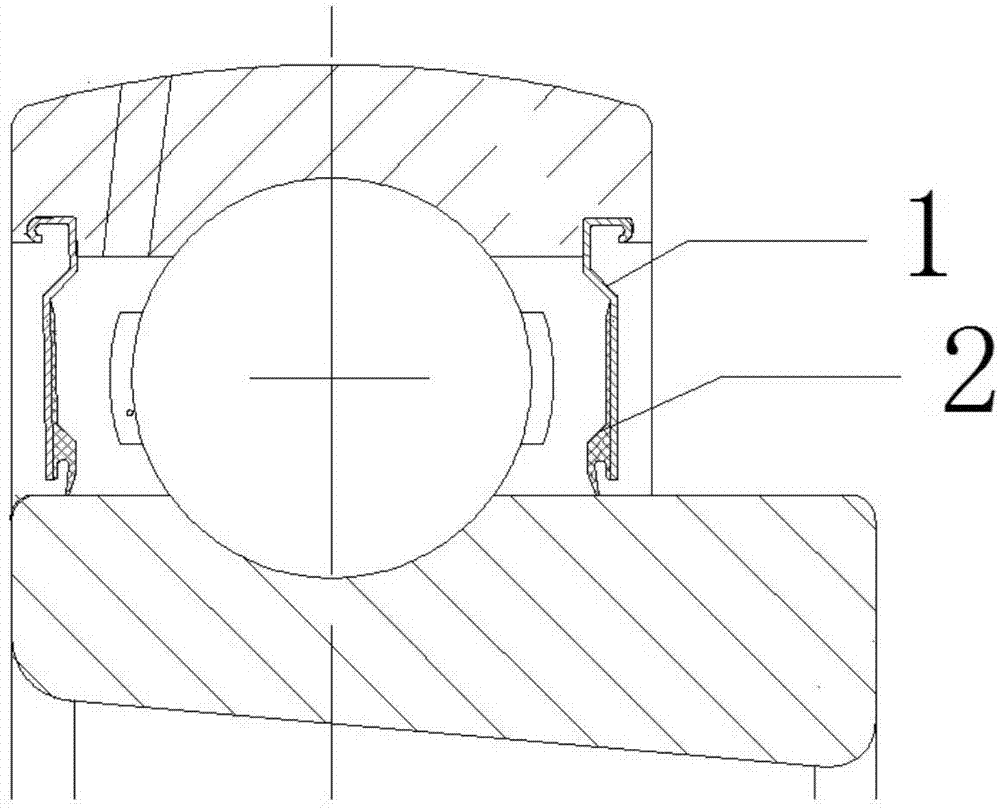

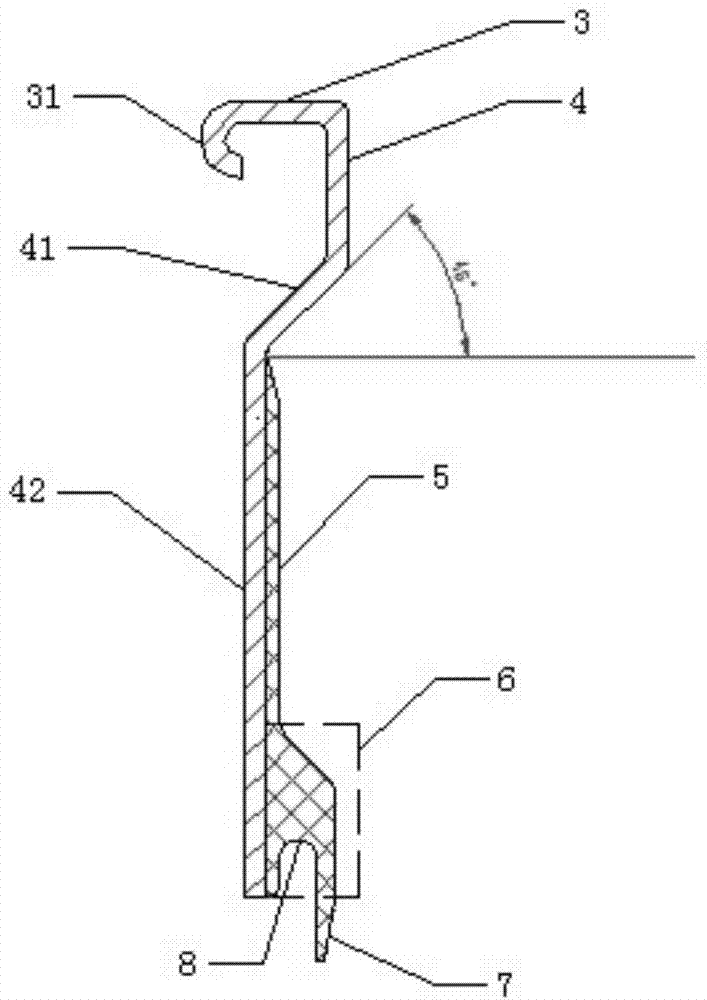

[0017] Embodiment 1: as figure 1 As shown, a bearing sealing ring includes an outer steel ring frame 1 and an inner rubber ring 2, the steel ring frame 1 includes a top beam 3 and a vertical beam 4, the top beam 3 is horizontally arranged, and the top The outer end 31 of the beam is bent in a C shape. The middle section 41 of the vertical beam one is bent at 45°, the rubber ring includes the vertical beam two 5 and the bottom beam 6, the vertical beam two 5 is bonded together with the lower section 42 of the vertical beam one of the steel ring skeleton, A sealing lip 7 is extended from the bottom beam of the rubber ring, and a C-shaped groove 8 is provided at the bottom of the bottom beam near the sealing lip.

[0018] By adopting the above technical solutions, the present invention can increase the elastic deformation capacity of the sealing ring, prolong its service life, and at the same time increase the clamping capacity of the sealing ring and the sealing notch of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com