Device for grinding high-precision outer circle

A high-precision, grinding technology, which is applied in the direction of machine tools designed for grinding the rotating surface of workpieces, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problem of difficulty in guaranteeing the dimensional accuracy and shape of the outer circle, and errors, etc. problem, to achieve the effect of simple and practical structure, obvious effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

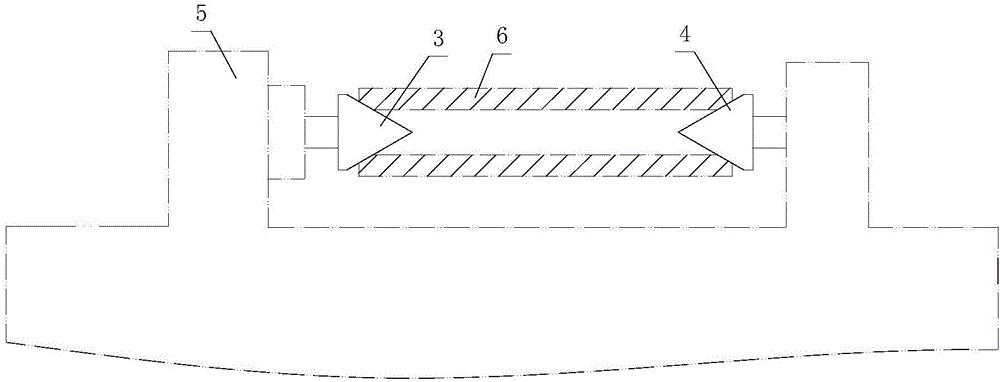

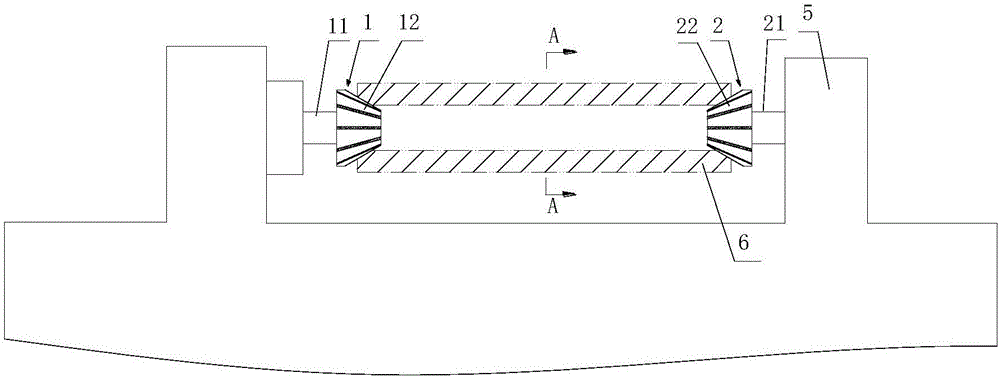

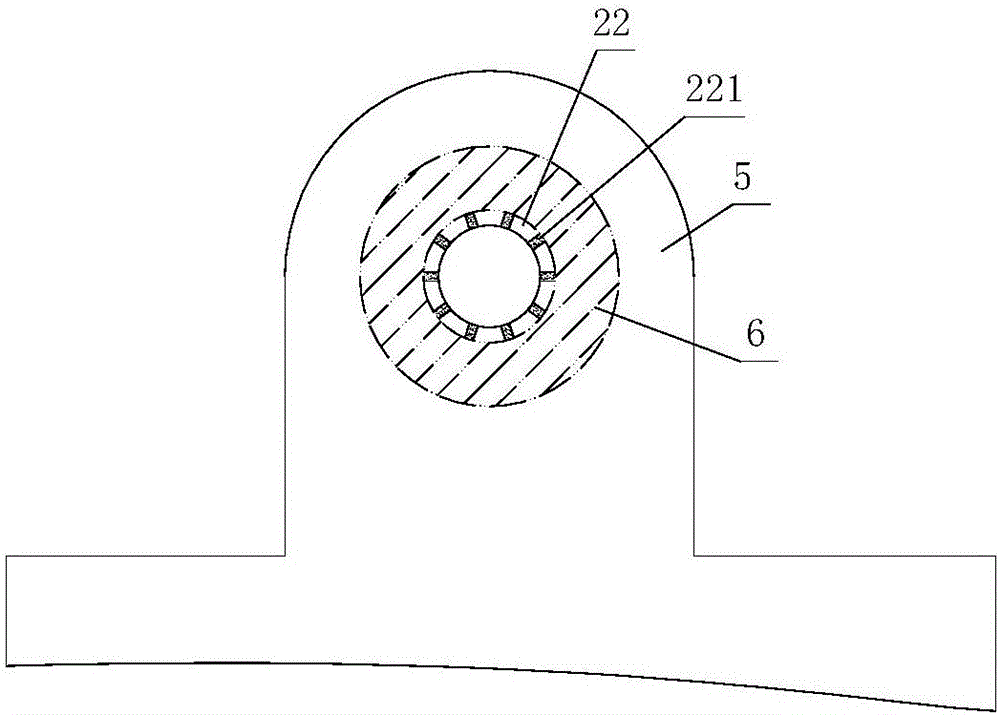

[0021] Such as Figures 2 to 7 As shown, a device for grinding a high-precision outer circle according to the present invention includes a left center 1 and a right center 2 respectively installed on the cylindrical grinder 5, and the left center 1 is connected by a left ejector rod 11 and a left center The left plug 12 on the push rod 11 is composed of a hard alloy insert A121 on the left plug 12; the right top 2 is composed of a right push rod 21 and a right plug 22 connected to the right push rod 21, and Carbide insert B221 is arranged on the right plug 22 . With this technical solution, during the machining process, the workpiece 6 is driven to rotate by the machine tool. During the rotation process, since the hardness of the cemented carbide insert A121 and the cemented carbide insert B221 are higher than the hardness of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com