Base part machining method and tool

A part processing and base technology, applied in the field of mechanical processing, can solve the problems of crushing, deformation, easy deformation, etc., and achieve the effect of eliminating deformation, eliminating convex and concave deformation, and improving cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for processing base parts, comprising the steps of:

[0037] Step 1) By controlling the machine tool speed, cutting depth and tool feed rate of the machine tool, the base parts are roughly machined in multiple feeds to remove large machining allowances;

[0038] Step 2) After rough machining, carry out the first vacuum heat treatment;

[0039] Step 3) For the base parts after the first vacuum heat treatment in step 2), the faceplate of the machine tool is fixed and aligned, and the base is semi-finished in multiple feeds by controlling the machine speed, cutting depth and tool feed rate of the machine tool Parts, semi-finishing base parts in multiple feeds;

[0040] Step 4) After semi-finishing, then carry out cryogenic heat treatment to further eliminate processing stress;

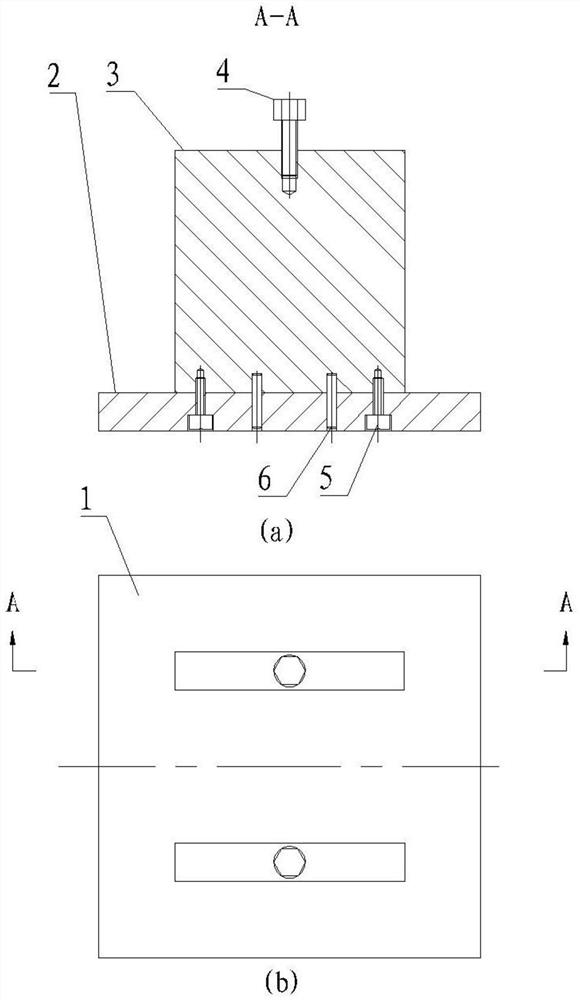

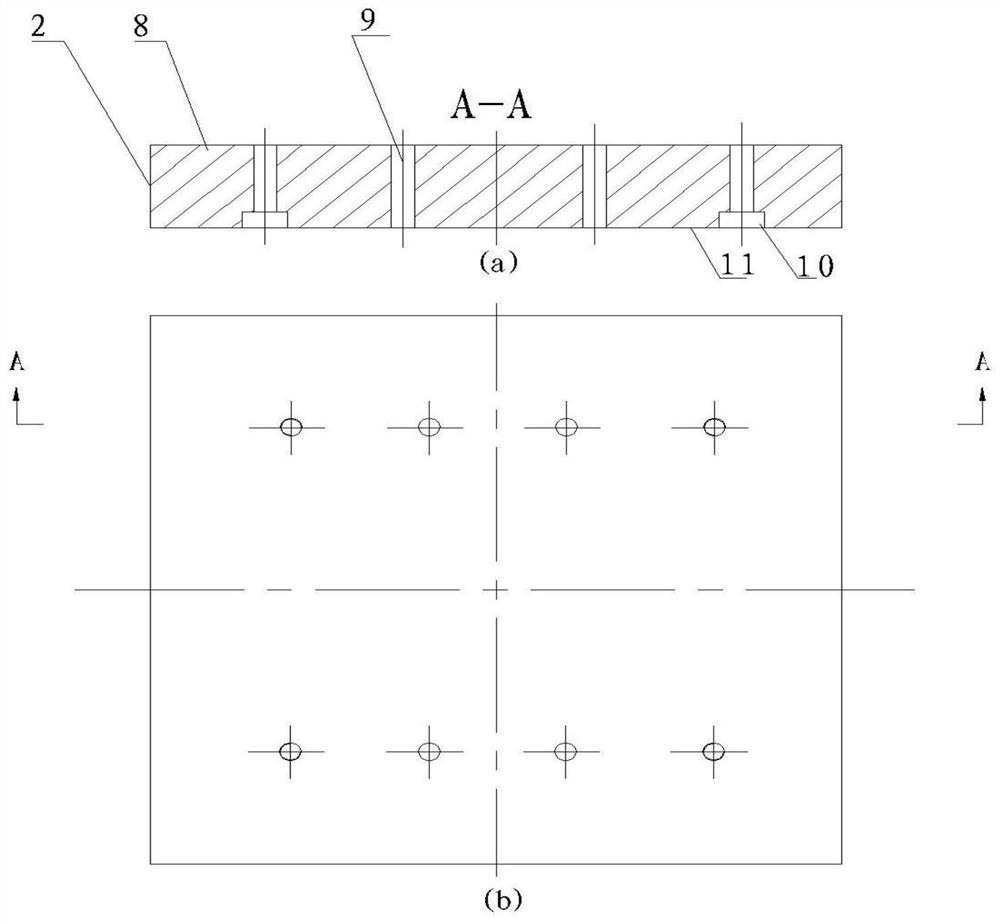

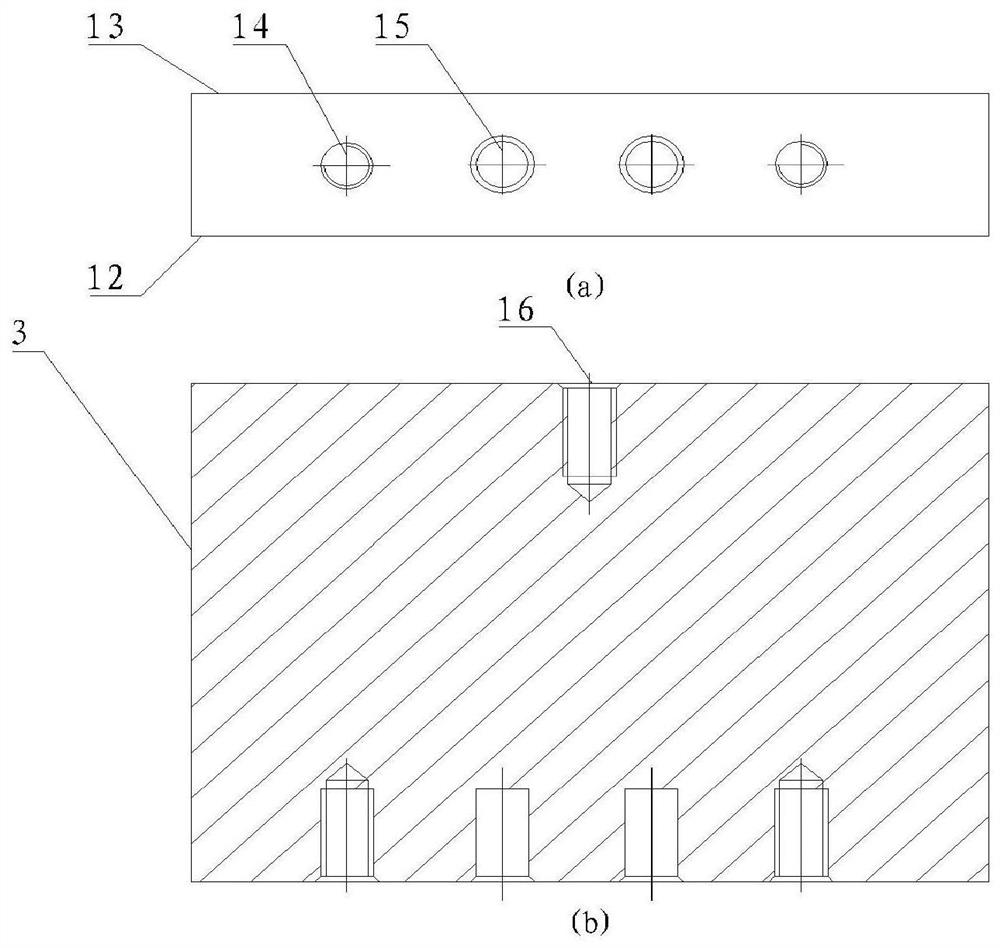

[0041]Step 5) Finishing the base part after the cryogenic heat treatment, adopting a grinding fixture for clamping and positioning, and completing the dimensional requirements for the fi...

Embodiment 2

[0045] A method for machining a base part, characterized by:

[0046] Step 1) First, use the three-jaw chuck of the machine tool to clamp the blank of the part. Under the conditions of the machine tool speed of 350-700rmin, the cutting depth of 2mm, and the feed rate of 0.5-0.25mm / r, the rough machining is divided into multiple feeds Base parts, remove large machining allowances;

[0047] Step 2) After rough machining, the vacuum is 6×10 -2 Pa, the temperature is 500±10°C, and the time is 3±0.1 hours, the hanging type is used to make the parts fully heated and evenly in the vacuum furnace, and the first vacuum heat treatment is carried out; the lattice structure is refined to prevent titanium Alloy materials react strongly with oxygen, nitrogen, and hydrogen in the atmosphere at high temperatures, forming hard and brittle layers such as TiO2, TiN, and TiH, which cause local stress concentration on the machined surface layer, reduce fatigue strength, and aggravate tool wear. ...

Embodiment 3

[0062] On the basis of Example 2, the invented measuring tool is used to directly measure the processing size after the parts are finished.

[0063] Such as Figure 8 As shown, the measuring tool includes a body 17, a shaft sleeve 18 and a pin shaft 19 with reticulated texture;

[0064] Such as Figure 9 As shown, the body 17 includes a third positioning surface 20, a bushing hole 21, a weight reduction hole 22, and a fourth positioning surface 23; Parallel, the lightening hole 22 is located at the center of the body 17, and the bushing holes 21 are distributed in a certain position on the pitch circle of the body 17 according to the technical requirements of the parts.

[0065] Such as Figure 10 As shown, the shaft sleeve 18 includes a fifth chamfer 24, a sixth chamfer 25, a matching cylinder 26, a seventh chamfer 27, an eighth chamfer 28, and a pin positioning hole 29; The sixth chamfer 25 and the seventh chamfer 27 and the eighth chamfer 28 are distributed at both ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com