Processing technology of threaded holes of inner ring of position marker

A technology of hole processing and position markers, which is applied in the direction of metal processing equipment, thread cutting auxiliary equipment, manufacturing tools, etc., can solve the problems of failing to meet the requirements of shape and position tolerances in design documents and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the utility model will be further described in conjunction with the embodiment in the accompanying drawing:

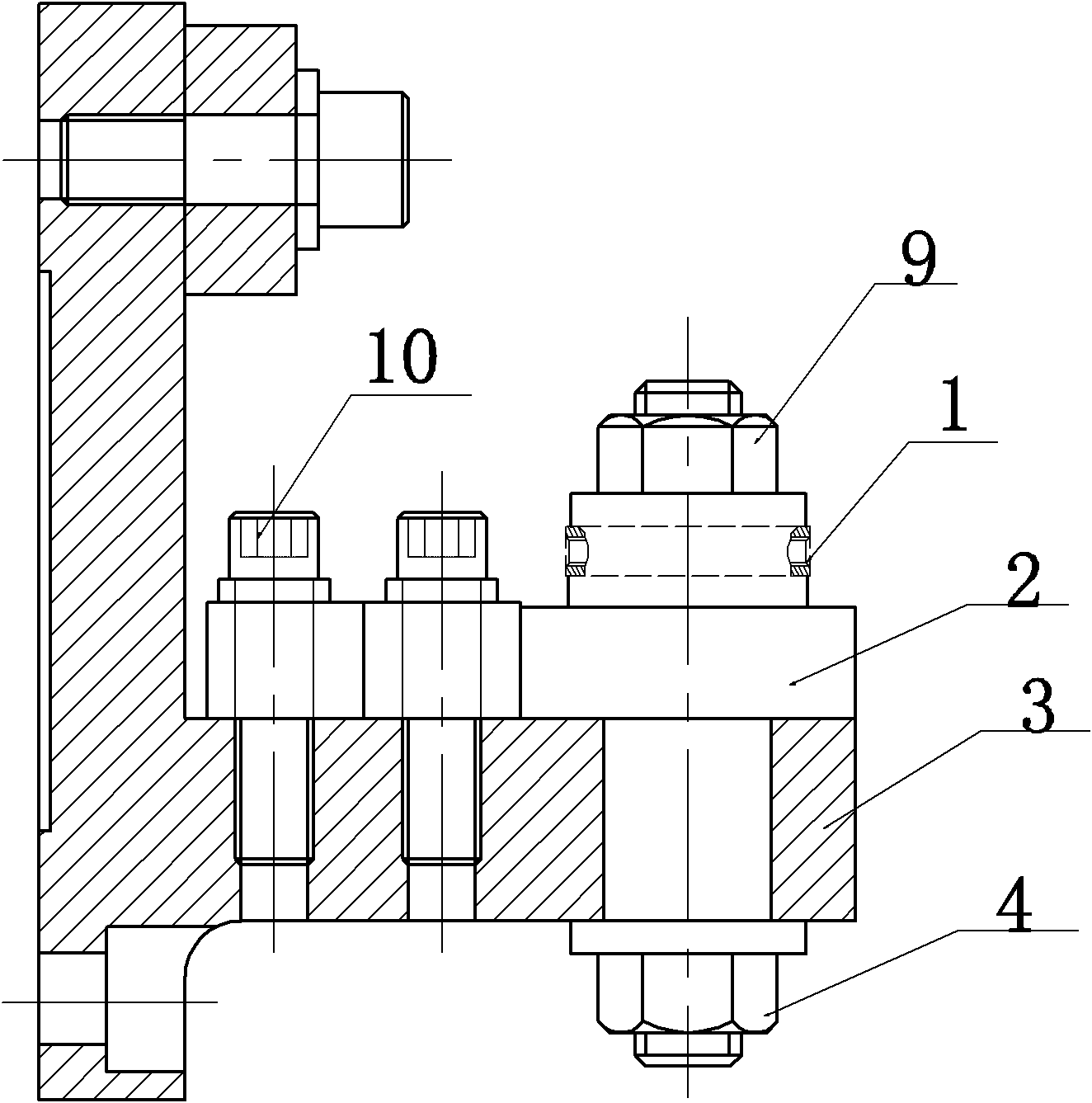

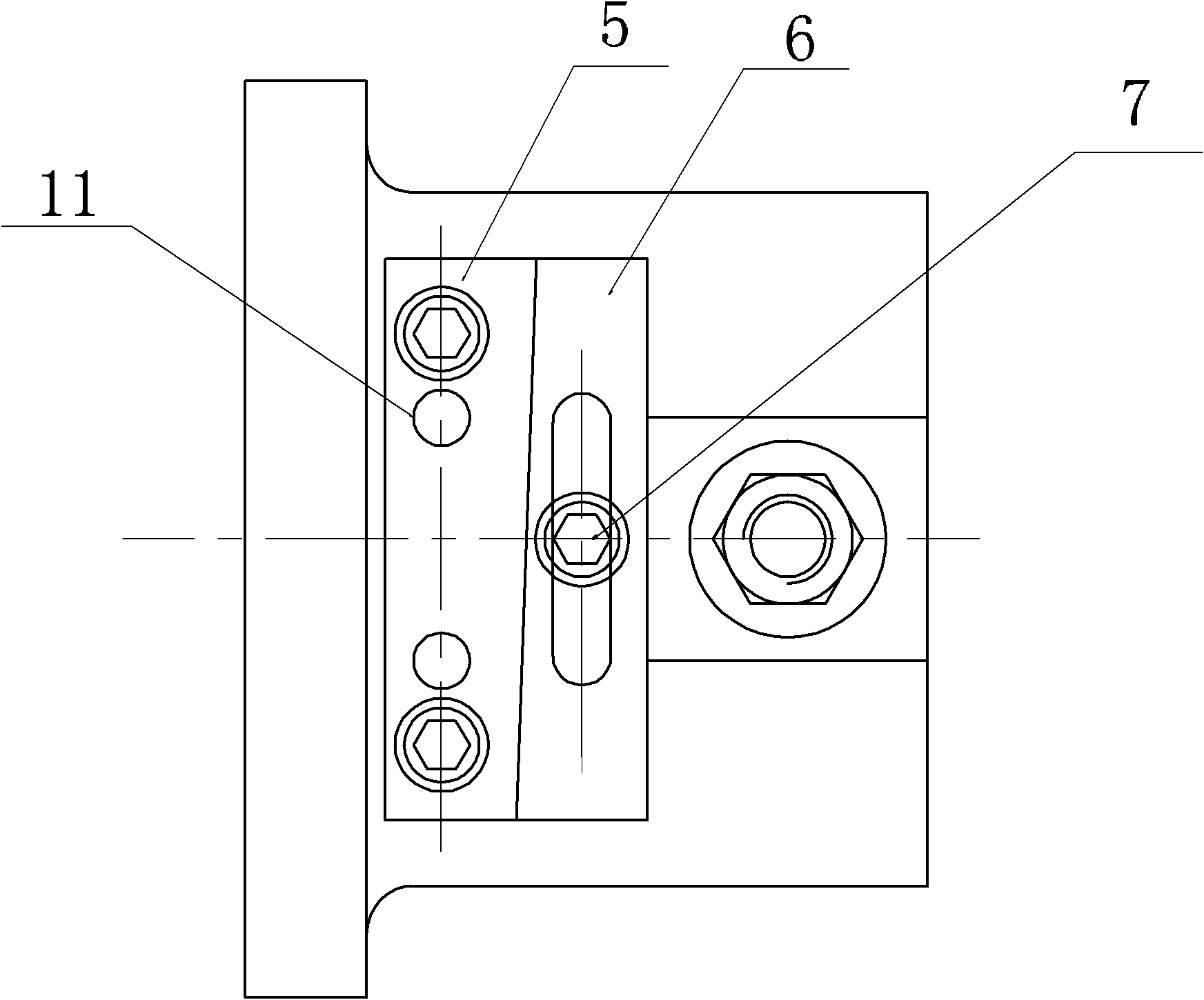

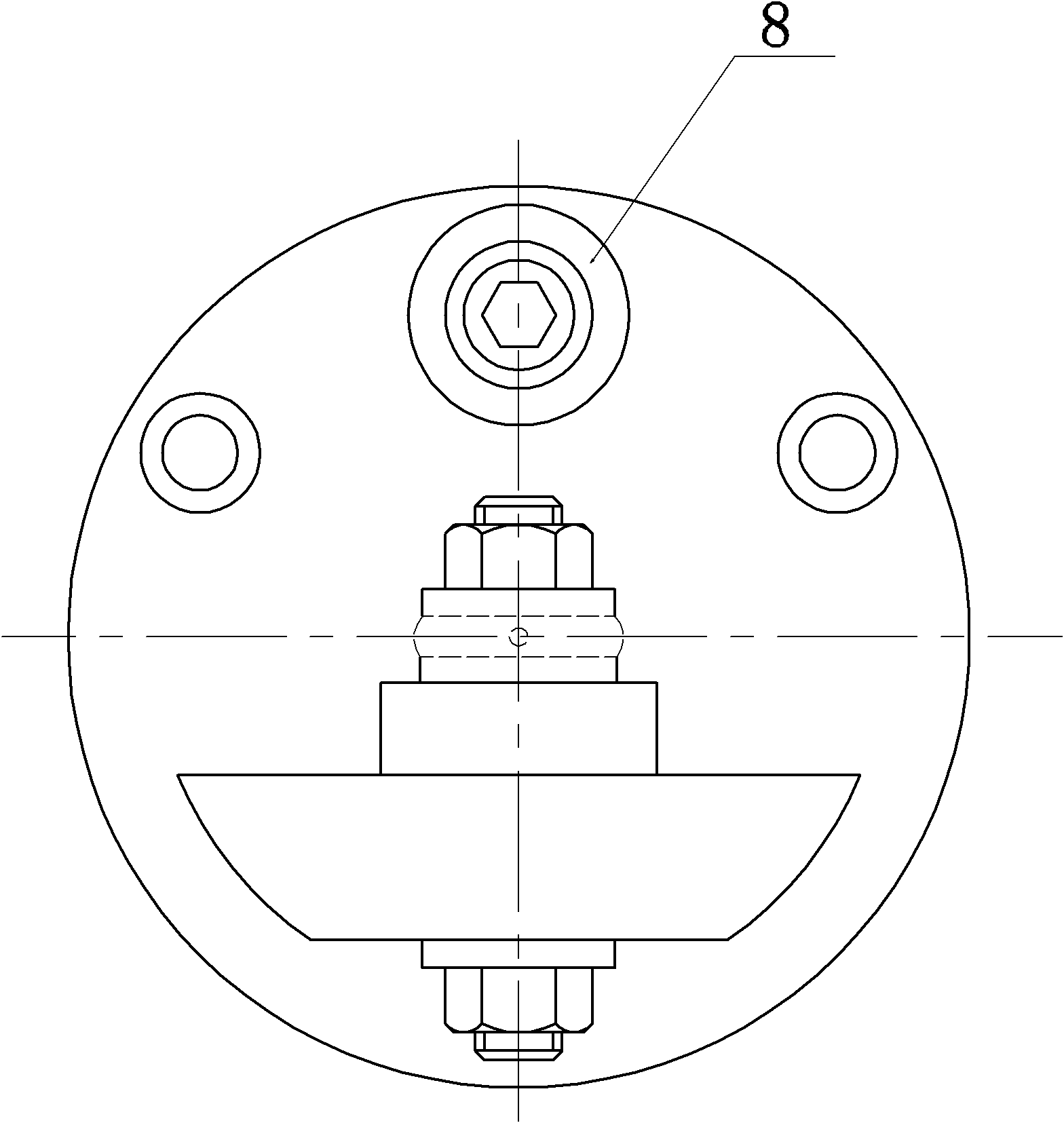

[0015] Such as 1~ image 3 Shown: Including the inner ring of the position marker 1, the limit mandrel 2, the clamp seat 3, the first integral nut 4, the fixing plate 5, the adjusting plate 6, the first hexagon socket screw 7, the counterweight 8, and the second integral Nut 9, second hexagon socket head cap screw 10, cylindrical pin 11.

[0016] The outer circle of the limiting mandrel 2 is installed in the positioning hole of the vehicle fixture seat 3 . The fixed plate 5 and the vehicle fixture seat 3 are fixedly connected together by two pins 11 and two hexagon socket head cap screws 10. The hypotenuse of the fixed plate 5 is in contact with the inclined surface of the adjustment plate 6. The adjustment plate 6 can be moved forward and backward to adjust the limit mandrel. angular position. Counterweight 8 is installed on the vehicle fixture seat 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com