Limb type circular tube node transferring structure and manufacturing method thereof

A technology for converting structures and manufacturing methods, applied in building structures, buildings, etc., can solve problems such as the design of bifurcated connection nodes of circular pipes, and achieve the effects of reducing residual stress, reducing overall deformation, and controlling welding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

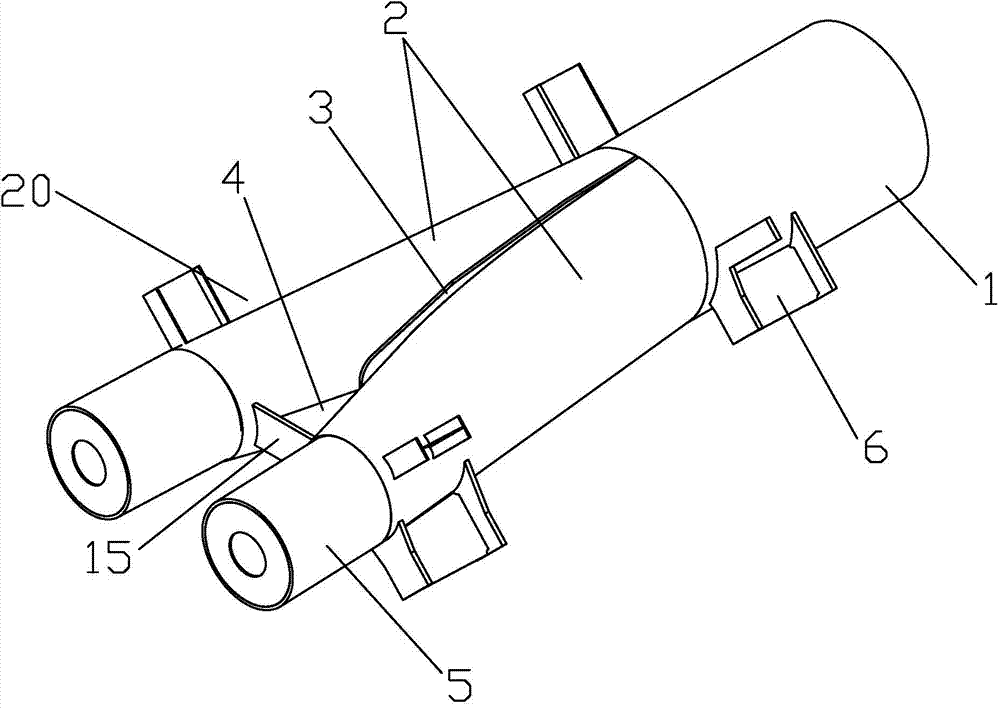

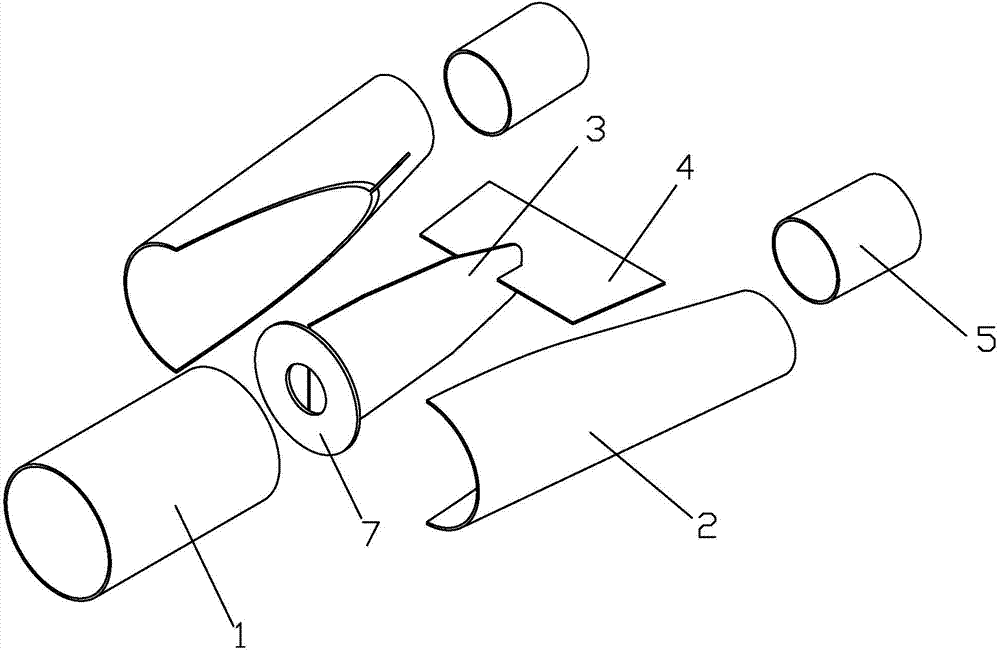

[0025] like figure 1 , 2 As shown, the present invention discloses a bark-type circular tube node conversion structure, including a trunk tube 1, a bifurcation transition node 20, a bark rod tube 5 and a space corbel 6 installed on the outer surface of the entire node, The bifurcation transition node 20 is formed by combining two special-shaped conical tubes 2 through the central pull plate 3 and the transverse inserting plate 4. The bottom of the bifurcation node is formed by combining the semicircles of the two special-shaped conical tubes 2 into a full circle, which is connected with the main round tube 1. , and the ends are connected to the round pipes 5 of the two tree branches.

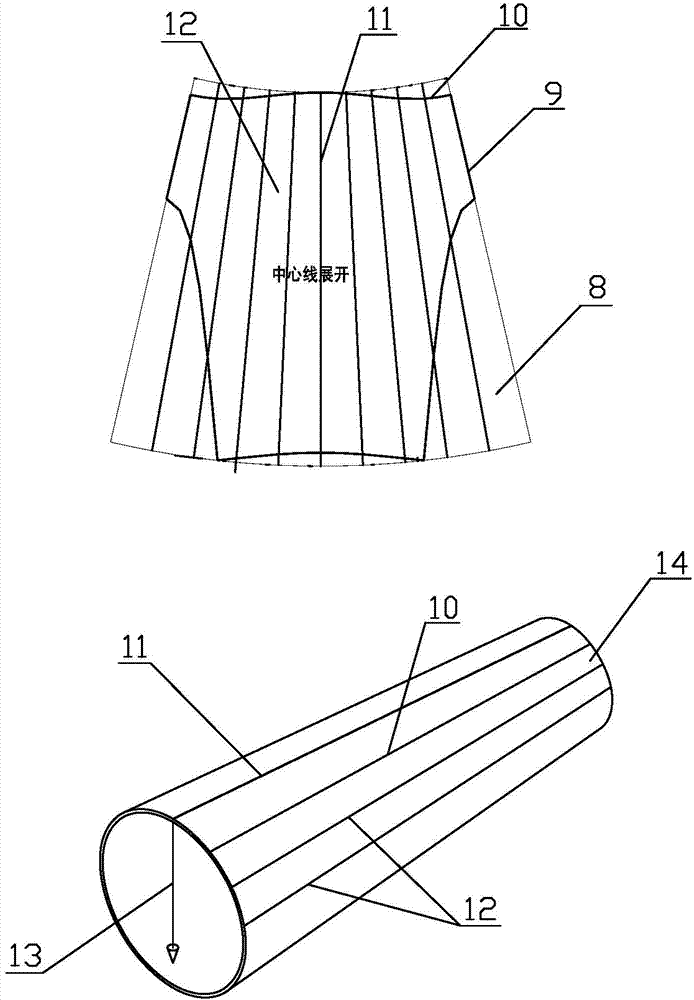

[0026] Further, the bottom section of the special-shaped tapered pipe 2 is a semicircular tile, and the side contour is an unclosed elliptic curve. The sides of the two special-shaped tapered tubes 2 are joined together by a central pull plate 3 in the middle. The two special-shaped tapered p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com