Forming technology for metal elastic sealing ring

A technology of elastic sealing and forming process, applied in the field of cold roll forming, can solve the problems of large forming size deviation, strip thickness reduction, cracking, etc., achieve the effect of small size deviation, small thickness change, and improve dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

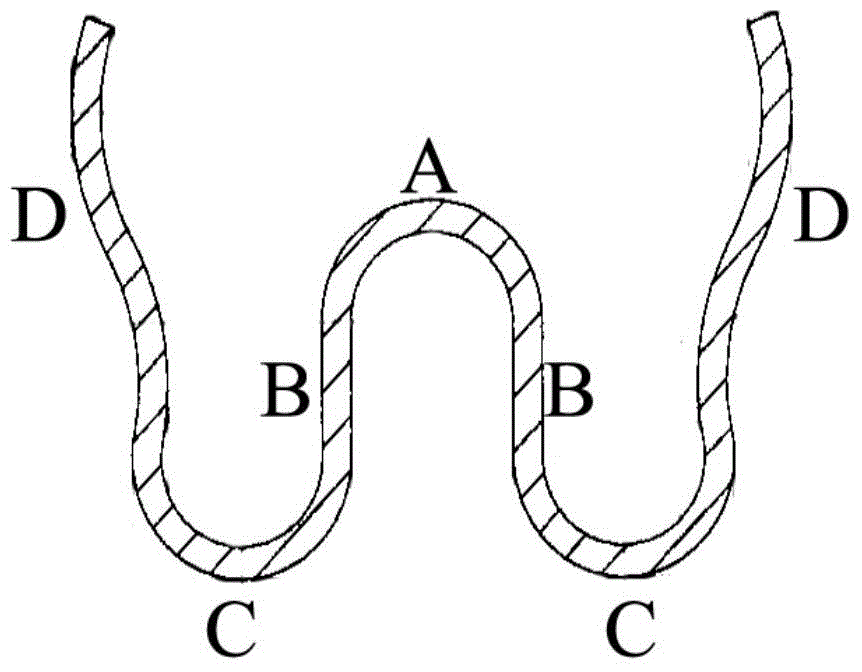

[0024] A molding process of a "W"-shaped metal elastic sealing ring, the ring section has a central curved arc A, two elastic curved arcs C, its interconnected straight connection part B and left and right convex arcs Contact surface D. The selected raw material is a nickel-based superalloy cold-rolled strip with a thickness of 0.28 mm.

[0025] Cut the strip into 22mm wide and 2.198m long according to the size of the finished product, and weld it into a ring; place the belt ring on the cold forming equipment, fix the ring, and spray lubricating oil all the time during the processing;

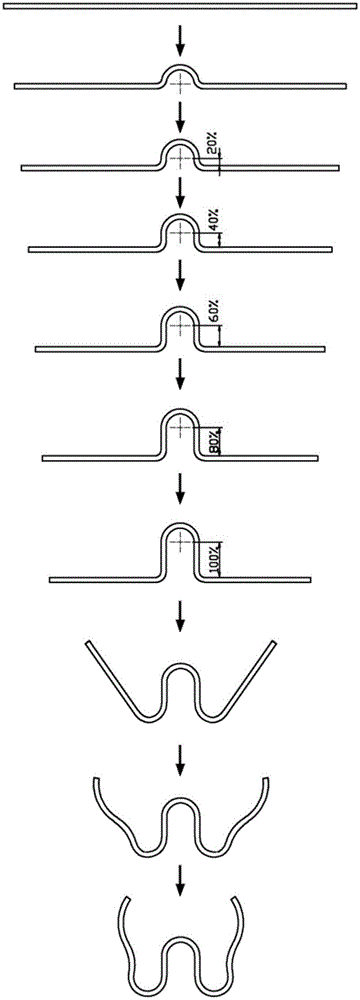

[0026] A molding process of a metal elastic sealing ring of the present invention specifically comprises the following steps:

[0027] Step 1: Put the ring on the cold bending forming equipment, use a set of cold bending rollers for spinning, the ring rotates around the center of the circle, and after one rotation, the middle part of the ring section forms a circular arc protrusion.

[0028] ...

Embodiment 2

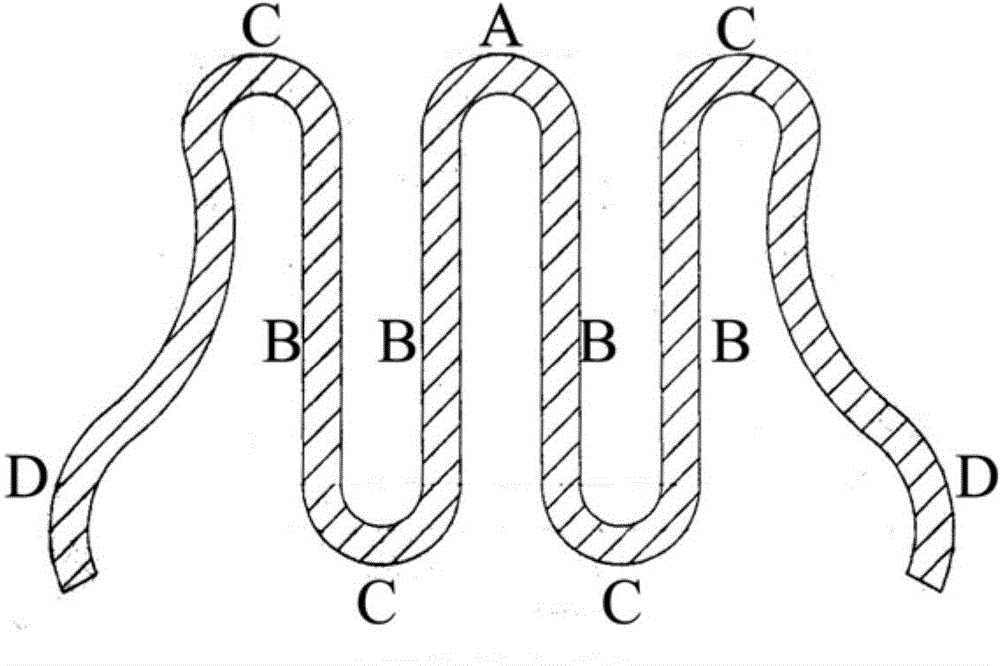

[0034] A molding process of a multi-curved "W"-shaped metal elastic sealing ring, the ring section has a central curved arc A, four elastic curved arcs C, its interconnected straight connecting parts B and left and right outer convex circles Arc-shaped contact surface D. The selected raw material is a nickel-based superalloy cold-rolled strip with a thickness of 0.4 mm.

[0035] Cut the strip into 36mm wide and 2.512m long according to the size of the finished product, and weld it into a ring; place the belt ring on the cold forming equipment, fix the belt ring, and spray lubricating oil all the time during the processing;

[0036] A molding process of a metal elastic sealing ring of the present invention specifically comprises the following steps:

[0037] Step 1: Same as Step 1 of Example 1.

[0038] Step 2: Same as Step 2 of Example 1.

[0039] Step 3: Same as Step 3 of Example 1.

[0040] Step 4: The ring does not move, replace the mold roll, position the mold roll wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com