Method for welding heat dissipation base plates

A heat dissipation bottom plate and welding method technology, applied in welding equipment, non-electric welding equipment, arc welding equipment, etc., can solve problems such as unbearable welding pressure, improve and repair weld structure and performance, ensure weld quality, control The effect of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a welding method for a heat dissipation bottom plate, comprising the following steps:

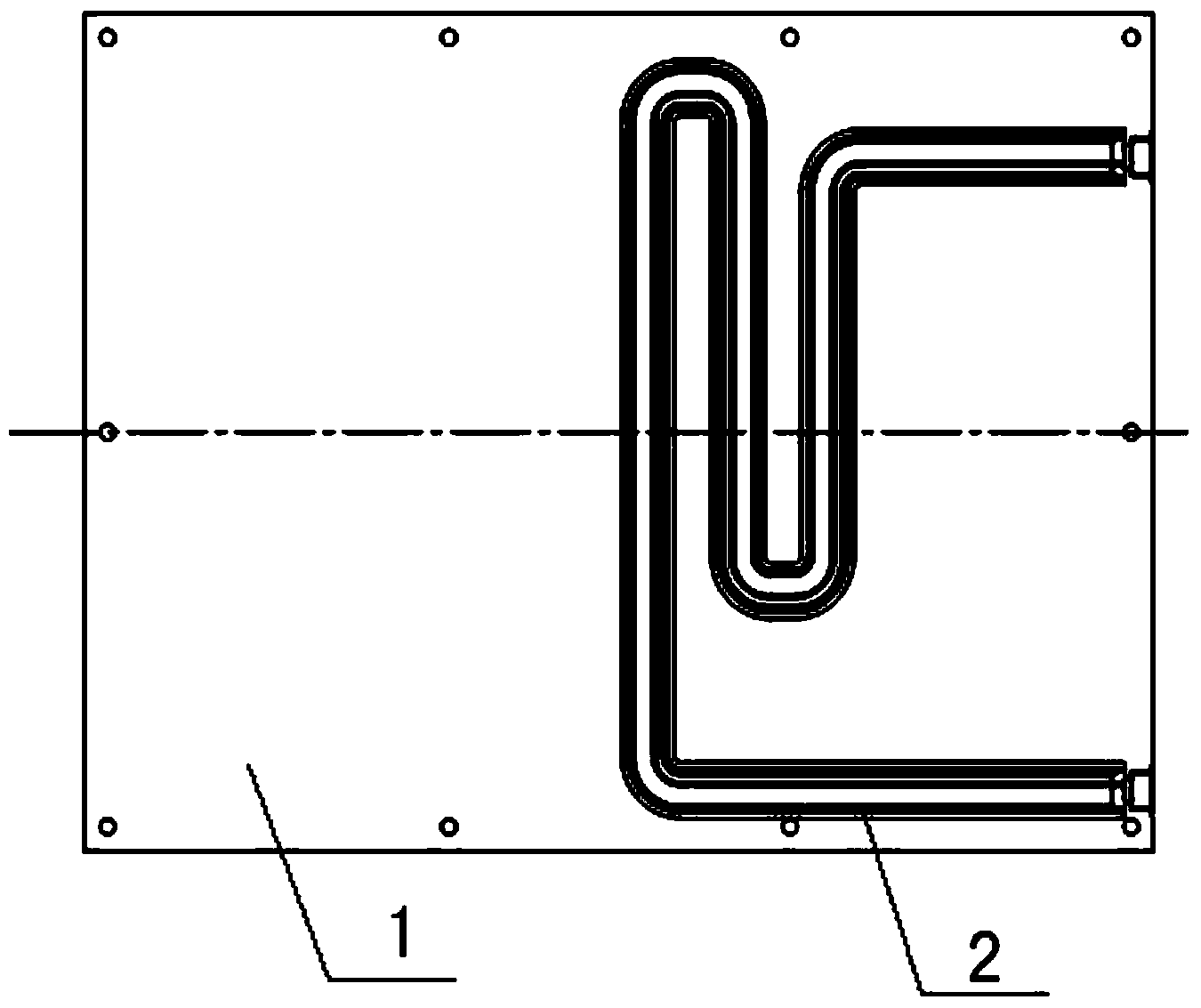

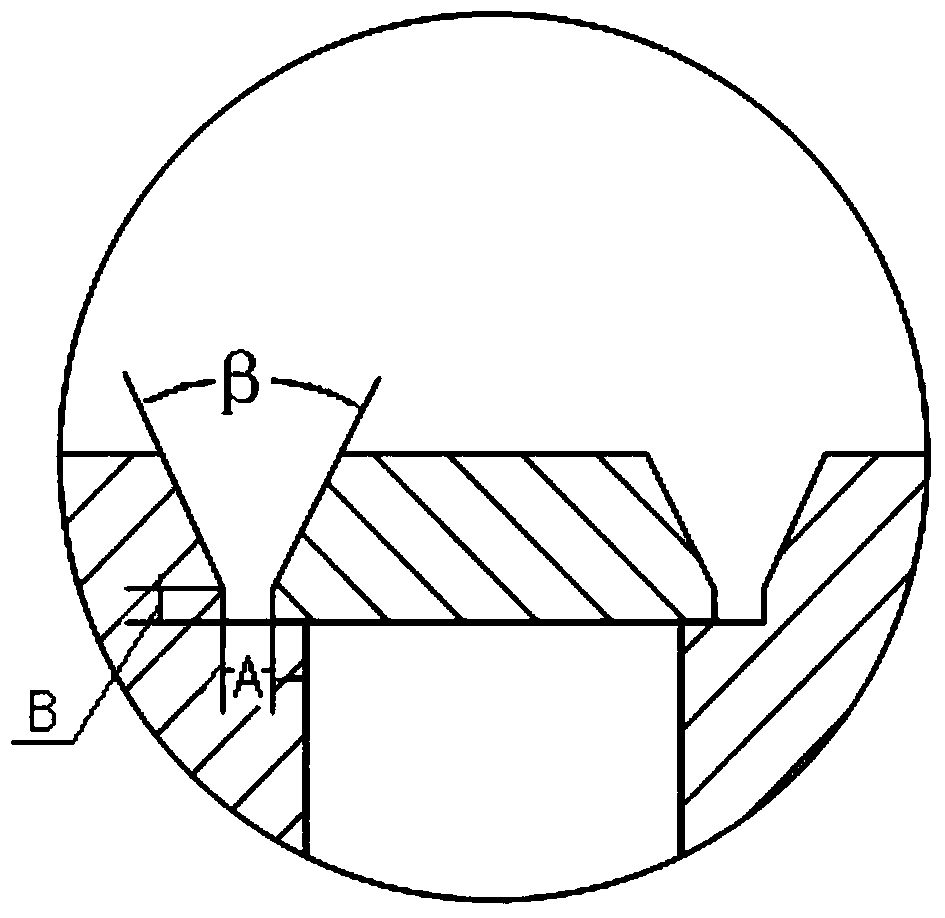

[0033] (1) Process the heat dissipation bottom plate: the heat dissipation bottom plate includes a bottom plate 1 and a cover plate 2, such as figure 1 shown. The material grade of the bottom plate 1 and the cover plate 2 is 5A06 aluminum alloy, wherein the thickness of the bottom plate 1 is 40 mm, and the total thickness of the cover plate 2 is 14 mm. Bottom plate 1 and cover plate 2 are processed by CNC milling method, and the welding seam is processed into trumpet-shaped groove 3, such as figure 2 shown. The gap of the horn-shaped groove 3 is A, the length of A is 3mm, the angle of the horn-shaped groove 3 is β, and β is 50 °, the blunt side of the horn-shaped groove 3 is B, and the length of B is 2mm.

[0034] (2) Clean the bottom plate 1 and the cover plate 2 with NaOH solution, and assemble the bottom plate 1 and the cover plate 2 on the welding too...

Embodiment 2

[0042] This embodiment provides a welding method for a heat dissipation bottom plate, comprising the following steps:

[0043](1) Process the heat dissipation bottom plate: the heat dissipation bottom plate includes a bottom plate 1 and a cover plate 2 . The material grade of the bottom plate 1 and the cover plate 2 is 5A06 aluminum alloy, wherein the thickness of the bottom plate 1 is 40 mm, and the total thickness of the cover plate 2 is 14 mm. The bottom plate 1 and the cover plate 2 are machined by numerical control milling, and the welds are processed into trumpet-shaped grooves 3 . The gap of the horn-shaped groove 3 is A, the length of A is 3mm, the angle of the horn-shaped groove 3 is β, and β is 50 °, the blunt side of the horn-shaped groove 3 is B, and the length of B is 2mm.

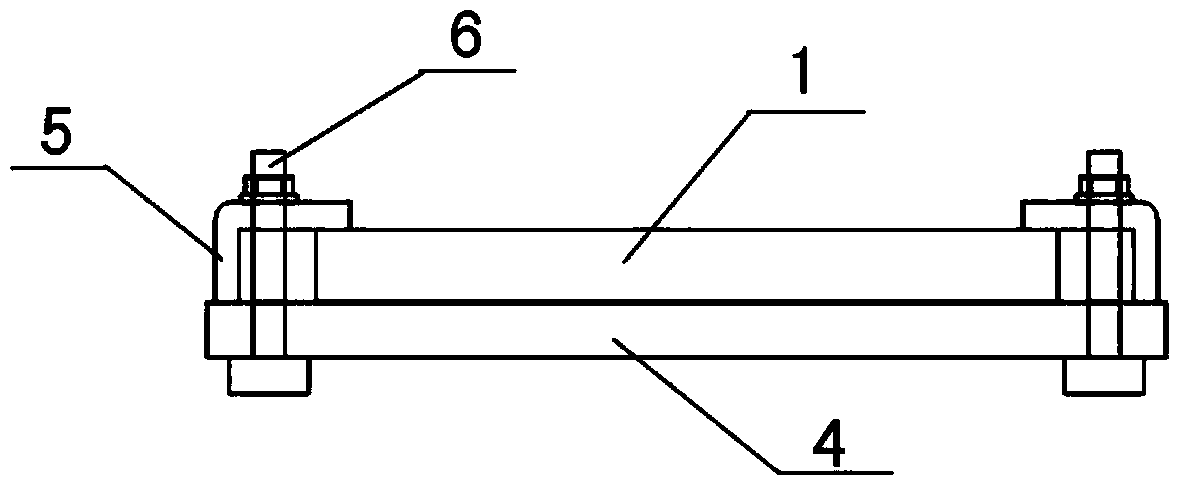

[0044] (2) Clean the bottom plate 1 and the cover plate 2 with NaOH solution, and assemble the bottom plate 1 and the cover plate 2 on the welding tool after cleaning. refer to image 3 , T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com