Vacuum electron beam welding method for thin-wall titanium alloy box structure with multiple cabin sections

A vacuum electron beam and electron beam welding technology, which is applied in the direction of electron beam welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of large welding deformation, error accumulation, and difficulty in achieving the shape accuracy of the box. To achieve the effect of air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

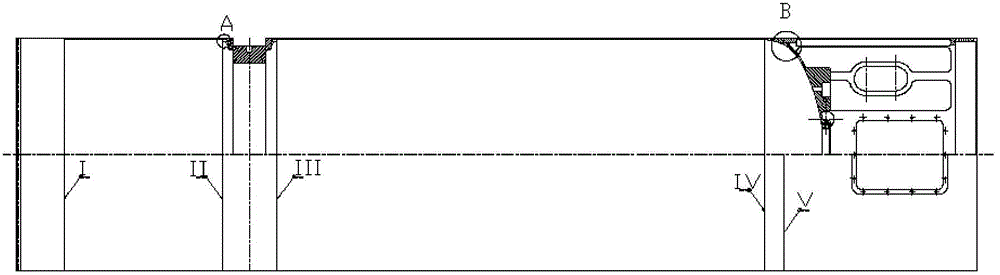

[0084] An electron beam welding method with a total length of 4560mm for a butt weld structure of a thin-walled (2mm) titanium alloy box (outer diameter 480mm) with six compartments and five girth welds.

[0085] Step 1: Preparation before welding

[0086] (1) Pickling the titanium alloy compartment to remove the oxide film and non-metallic impurities on the surface of the parts, and place it in a low-vacuum clean environment to ensure electron beam welding within 24 hours.

[0087] (2) Grind the joints of each component (especially the joint end face) with a wind brush until the metallic luster is exposed, and wipe it clean with a white silk cloth dipped in acetone. No oil, fingerprints, thread ends, impurities, etc. are allowed.

[0088] Step 2: Assembly Tooling

[0089] (1) Pre-set copper skin in the box to prevent the electron beam from damaging the opposite box.

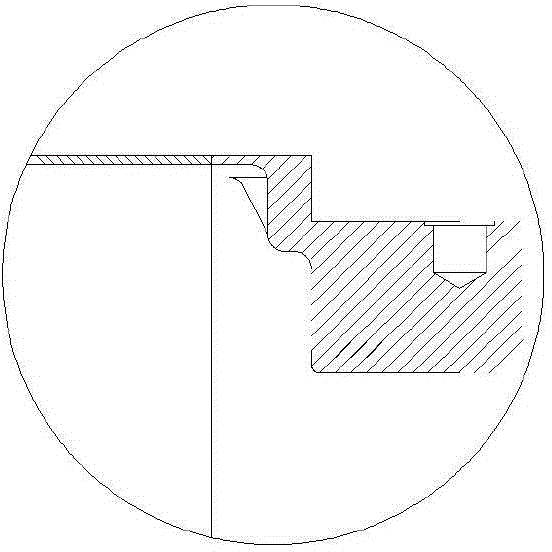

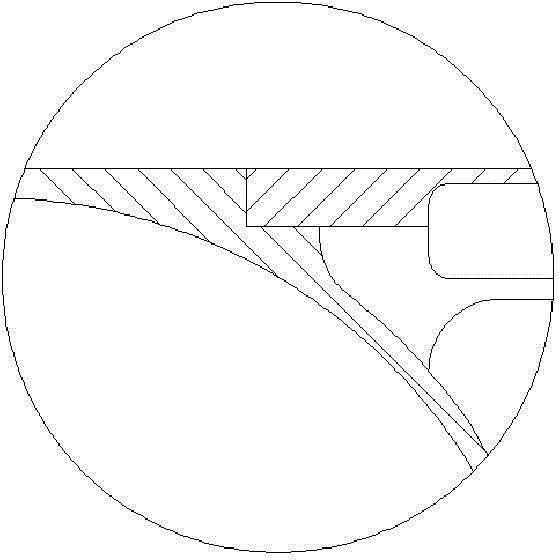

[0090] (2) adopt Figure 4 The ring welding tooling in Figure 5 and the external pressure snap ring toolin...

Embodiment 2

[0106] An electron beam welding method with a total length of 3500mm for a butt weld structure of a thin-walled (3mm) titanium alloy box (outer diameter 600mm) with four compartments and three girth welds.

[0107] Step 1: Preparation before welding

[0108] (1) Pickling the titanium alloy compartment to remove the oxide film and non-metallic impurities on the surface of the parts, and place it in a low-vacuum clean environment to ensure electron beam welding within 24 hours.

[0109] (2) Grind the joints of each component (especially the joint end face) with a wind brush until the metallic luster is exposed, and wipe it clean with a white silk cloth dipped in acetone. No oil, fingerprints, thread ends, impurities, etc. are allowed.

[0110] Step 2: Assembly Tooling

[0111] (1) Pre-set copper skin in the box to prevent the electron beam from damaging the opposite box.

[0112] (2) adopt Figure 4 The girth welding tooling () and Figure 6 The external pressure snap ring t...

Embodiment 3

[0128] An electron beam welding method with a total length of 1500mm for a bottom-locked structure of a thin-walled (1.8mm) titanium alloy box (outer diameter 400mm) with two compartments and one girth weld.

[0129] (1) Pickling the titanium alloy compartment to remove the oxide film and non-metallic impurities on the surface of the parts, and place it in a low-vacuum clean environment to ensure electron beam welding within 24 hours.

[0130] (2) Grind the joints of each component (especially the joint end face) with a wind brush until the metallic luster is exposed, and wipe it clean with a white silk cloth dipped in acetone. No oil, fingerprints, thread ends, impurities, etc. are allowed.

[0131] Step 2: Assembly Tooling

[0132] (1) Pre-set copper skin in the box to prevent the electron beam from damaging the opposite box.

[0133] (2) adopt Figure 4 The girth welding tooling and the external pressure snap ring tooling shown in Figure 5 are used to assemble the compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cylindricity | aaaaa | aaaaa |

| Cylindricity | aaaaa | aaaaa |

| Cylindricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com