Dual-dovetail type unmovable key bar assembling and welding process for water turbine generator

A hydro-generator, mobile positioning technology, applied in arc welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems of long installation cycle, affecting the accuracy of positioning rib installation and welding, positioning rib installation and adjustment, and complicated welding process. , to save the installation cycle, improve dimensional accuracy, and save the workload of repeated adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

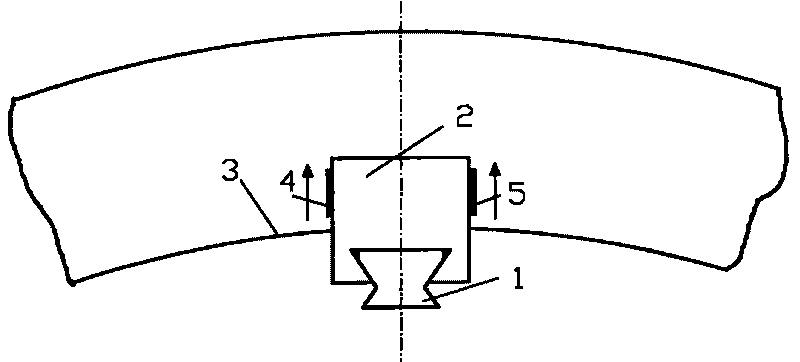

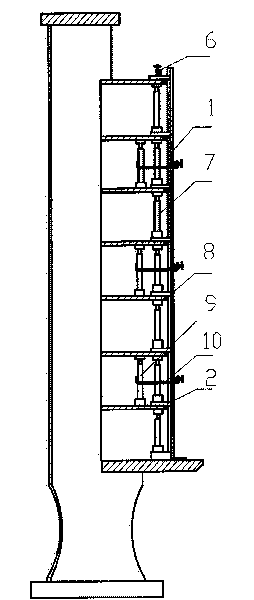

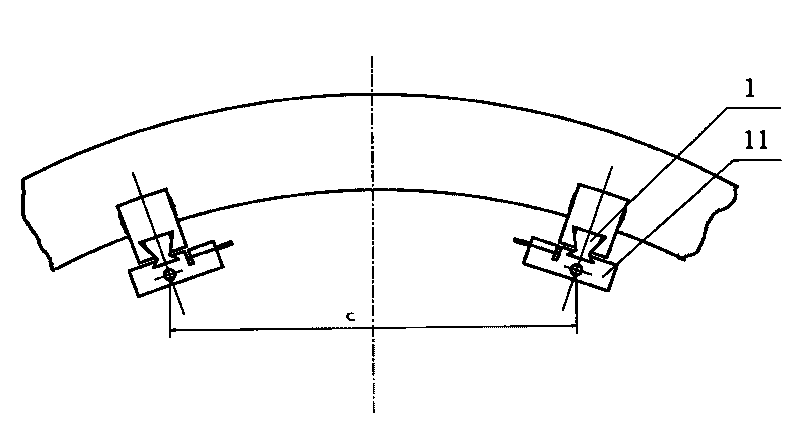

[0015] A hydroelectric generator double dovetail non-removable positioning rib assembly welding process, the above method includes the following process steps:

[0016] (1) According to the welding experience value of Harbin Electric’s traditional structural positioning ribs (the support block has a circumferential weld) and the structural characteristics of the double dovetail positioning ribs, determine the lap welding radius process tolerance R of the double dovetail non-movable positioning ribs -0.15 +0.15 mm;

[0017] (2) The double dovetail positioning ribs are installed in equal parts with a large span, and the large span of the positioning ribs is an integer equal division of the total number of double dovetail positioning ribs, generally 3, 6, 8 or 9 equal divisions. Divide the accumulative error of positioning tendon distance adjustment equally among the major spans to reduce the circumferential accumulation of positioning tendon distance adjustment error values;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com