Numerical simulation method for axial flow pump blade tip gap leakage vortex cavitation

A technology of blade tip clearance and numerical simulation, applied in CAD numerical modeling, complex mathematical operations, electrical digital data processing, etc., can solve problems such as shortage, large difference, underestimation, etc., achieve high-precision numerical prediction, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

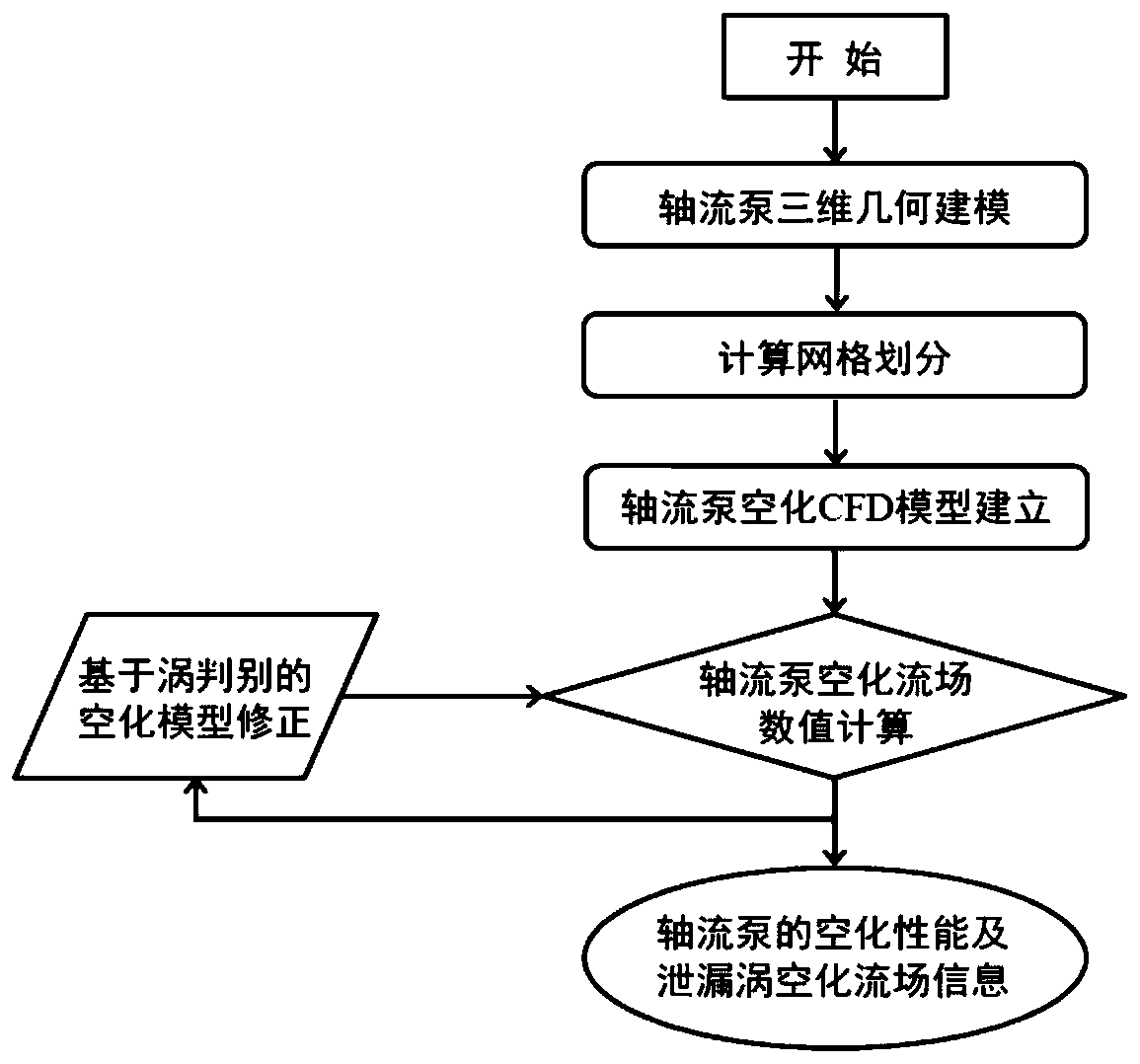

[0052] A numerical simulation method of vortex cavitation in blade tip clearance leakage of axial flow pump, such as figure 1 As shown, it is mainly realized by the following steps:

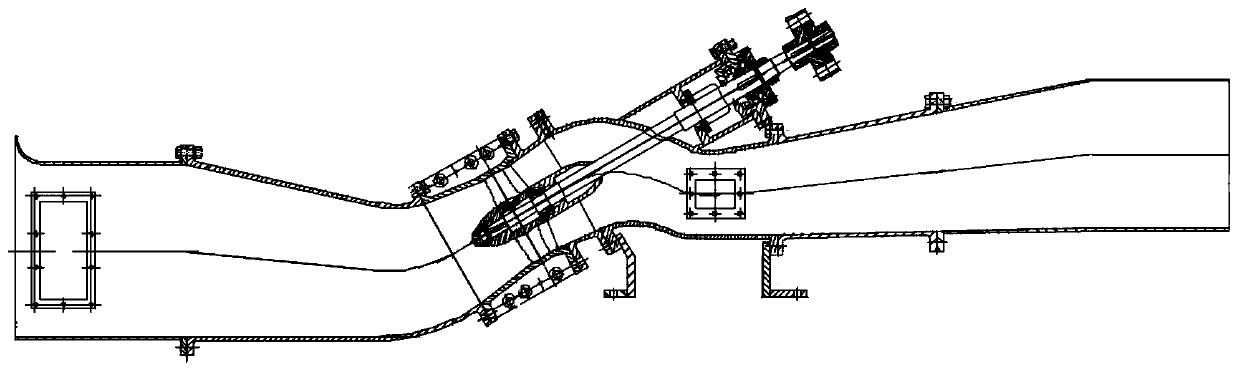

[0053] Step 1: Three-dimensional geometric modeling of the axial flow pump, according to the given design drawings of the axial flow pump, such as figure 2 As shown, the three-dimensional geometric model of the axial flow pump is established by using the geometric modeling software Croe, and the *.igs format file is output. The equivalent diameter of the inlet section of the axial flow pump inlet channel D1 = 0.75m, and the equivalent diameter of the outlet section of the outlet channel D2 = 0.4 m, the length D3=D1=0.75m of the extension section at the inlet of the axial flow pump inlet, and the length D4=5D2=2.0m of the extension section at the outlet of the axial flow pump outlet;

[0054] Step 2: Calculate mesh division, import the *.igs geometry file created and output in step 1 into the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com