Double-steel-pipe concrete beam-column joint with built-in FRP rib connecting device and mounting method

A technology of double steel tube concrete and connecting device, applied in the direction of columns, piers, pillars, etc., can solve the problems of high construction requirements on welding sites, large welding residual stress, poor quality control, etc., and achieve excellent tensile performance and fatigue resistance. Load capacity, enhance safety and bearing capacity, improve the effect of seismic energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

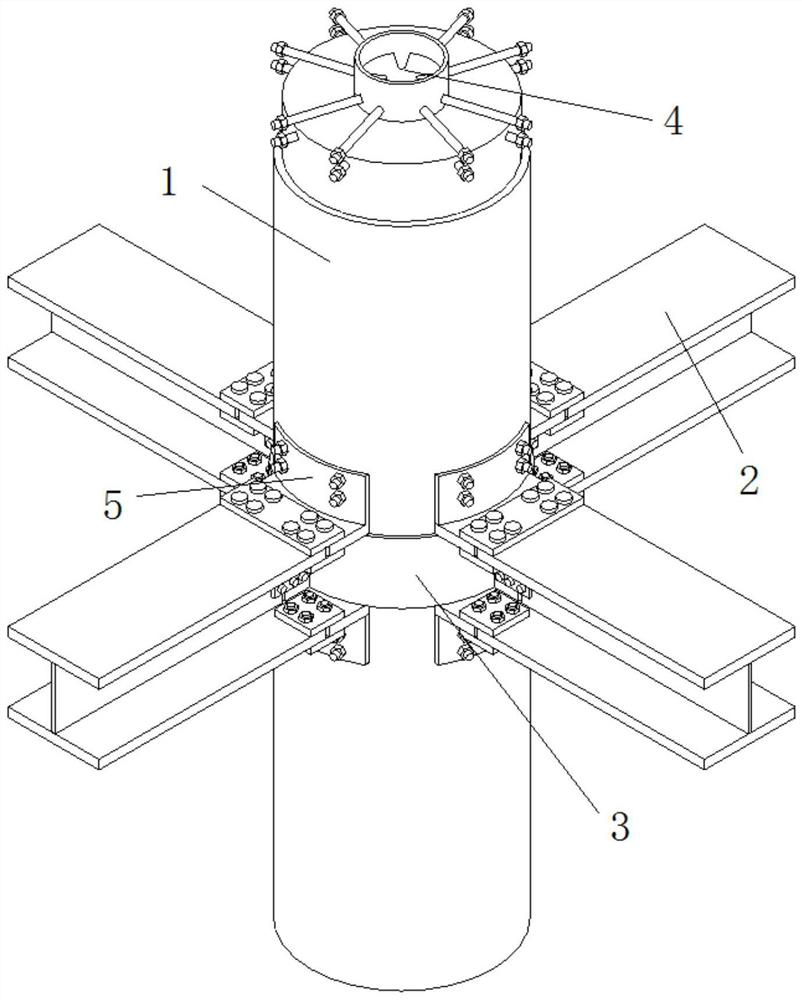

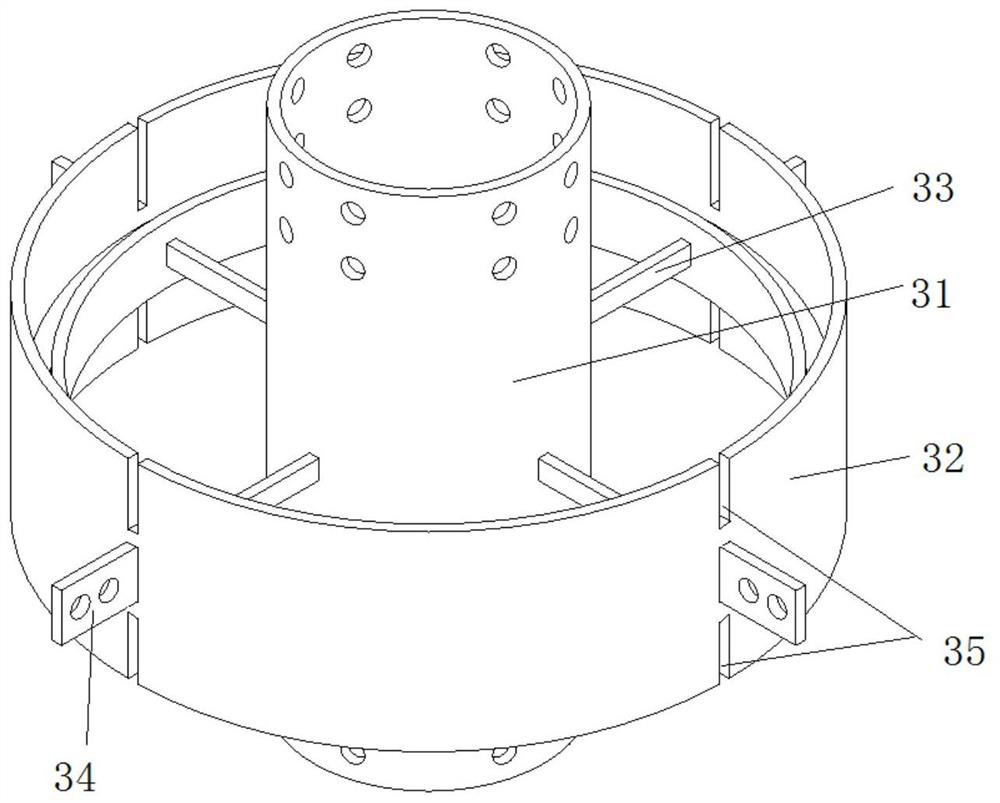

[0045] Such as figure 1 As shown, the double steel pipe concrete beam-column node with the built-in FRP tendon connection device of the present invention includes a double steel pipe column 1, an I-beam 2, a node connector 3, an inner support 4 and an outer ring plate 5.

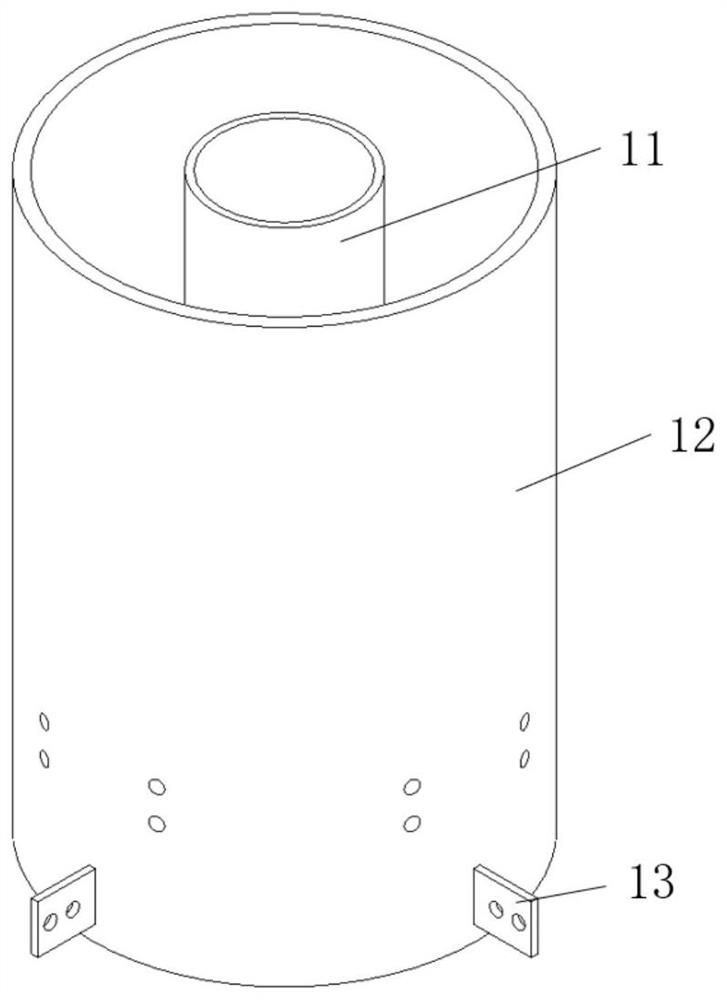

[0046] Such as figure 2 As shown, the double steel pipe column 1 includes an inner steel pipe 11 and an outer steel pipe 12. Both the inner steel pipe and the outer steel pipe are round steel pipes, and the near node end of the outer steel pipe is vertically fixed with a connecting ear I13, that is, the bottom of the upper outer steel pipe and the lower outer steel pipe The outer surface of the top of the top is vertically fixed with connecting ears I13, and the number of connecting ears I13 is consistent with the number of I-beams 2 to be connected. In this embodiment, four I-beams 2 are connected as an example, and the four connecting ears Ⅰ13 are evenly distributed along the circumference; the bottom of...

Embodiment 2

[0062] Such as Figure 5 As shown, in order to reduce the material and weight, the middle of the inner support 4 can be hollowed out, and the parts with bolt holes at both ends are reserved. The inner support 4 includes round members 41 at both ends and connecting rods 42 in the middle. The components 41 are connected by connecting rods 42 , and bolt holes are uniformly distributed along the circumference of the circular component 41 .

[0063] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com