U-shaped-hoop joint connector of main beam and auxiliary beam of recombinant-bamboo frame

A technology of node connection and reorganization of bamboo, applied in the direction of architecture, building structure, etc., can solve problems such as immaturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

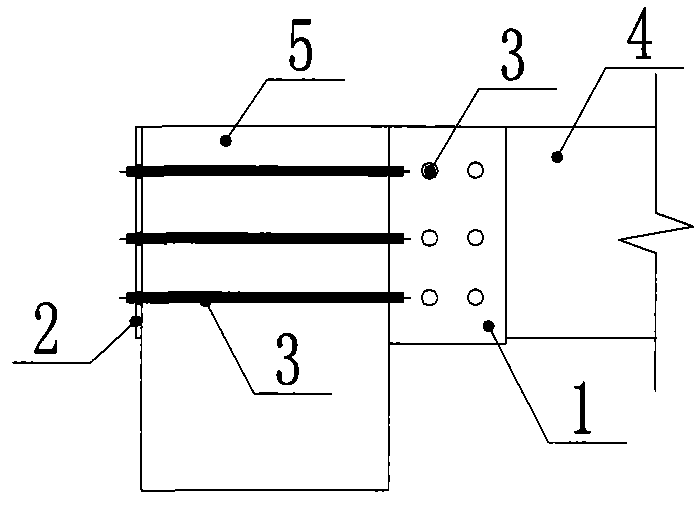

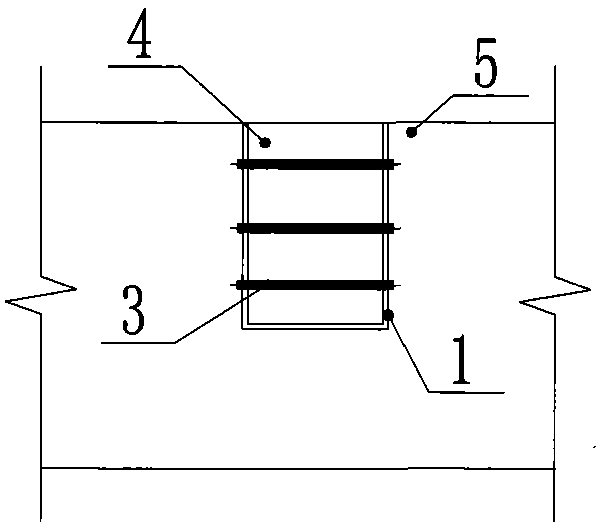

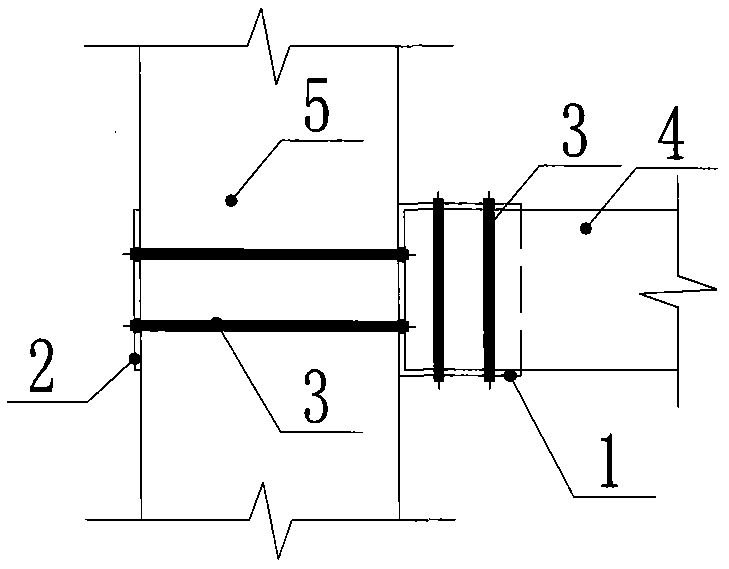

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

[0014] Such as Figure 1~4 As shown, a U-shaped hoop joint connection of primary and secondary beams of a restructured bamboo frame is characterized in that: the beam-column joint connection mainly includes U-shaped hoops, gusset plates, bolts, reorganized bamboo frame beams, and reorganized bamboo frame columns. The recombined bamboo is a new bamboo material that reorganizes and strengthens bamboo. The use of recombined bamboo for the main beam of the frame is called the main beam of the recombined bamboo frame; the use of recombined bamboo for the secondary beam of the frame is called the secondary beam of the recombined bamboo frame. The U-shaped hoop is welded by one end plate, two joint plates and a bottom plate, placed on the side of the main beam of the restructured bamboo frame, and the secondary beam of the reorganized bamboo frame is placed on the top of the U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com