Impact type electric compression joint or shearing pliers

A percussive, electric technology used in pliers, portable devices, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

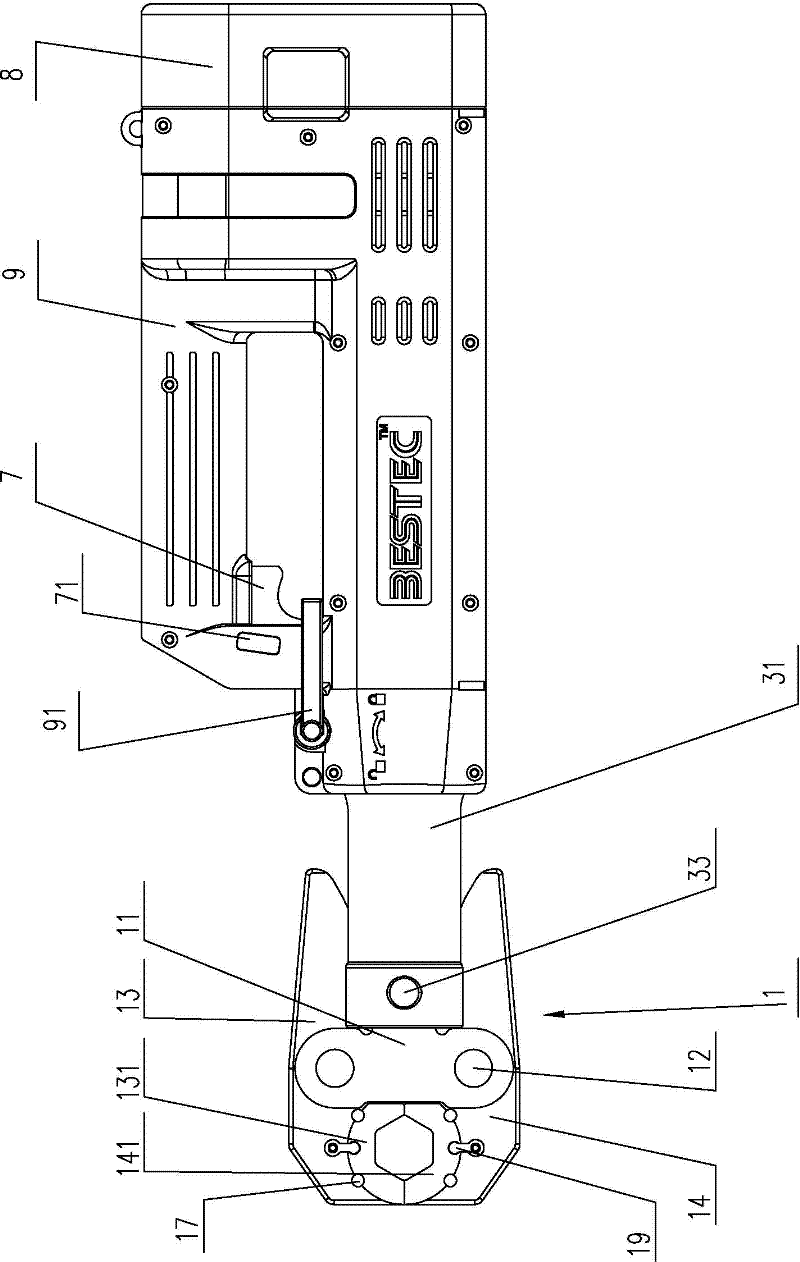

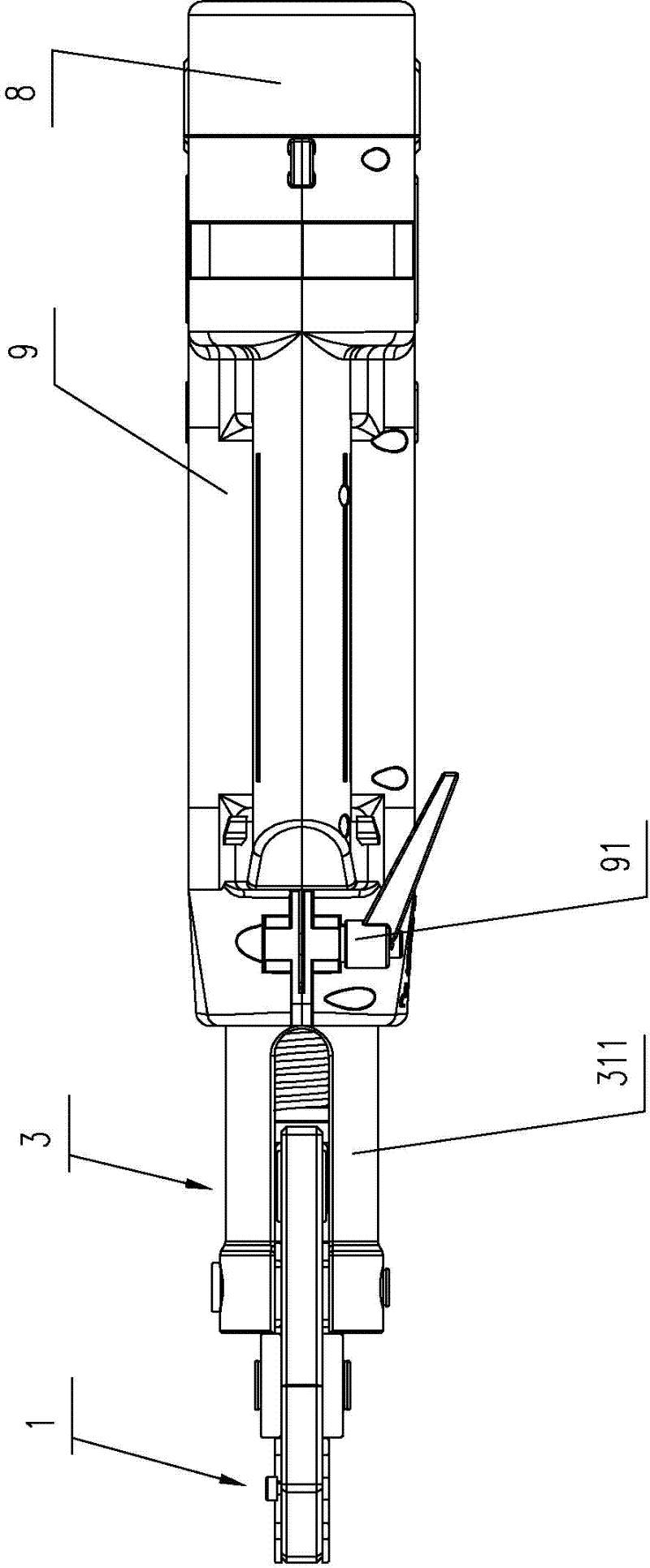

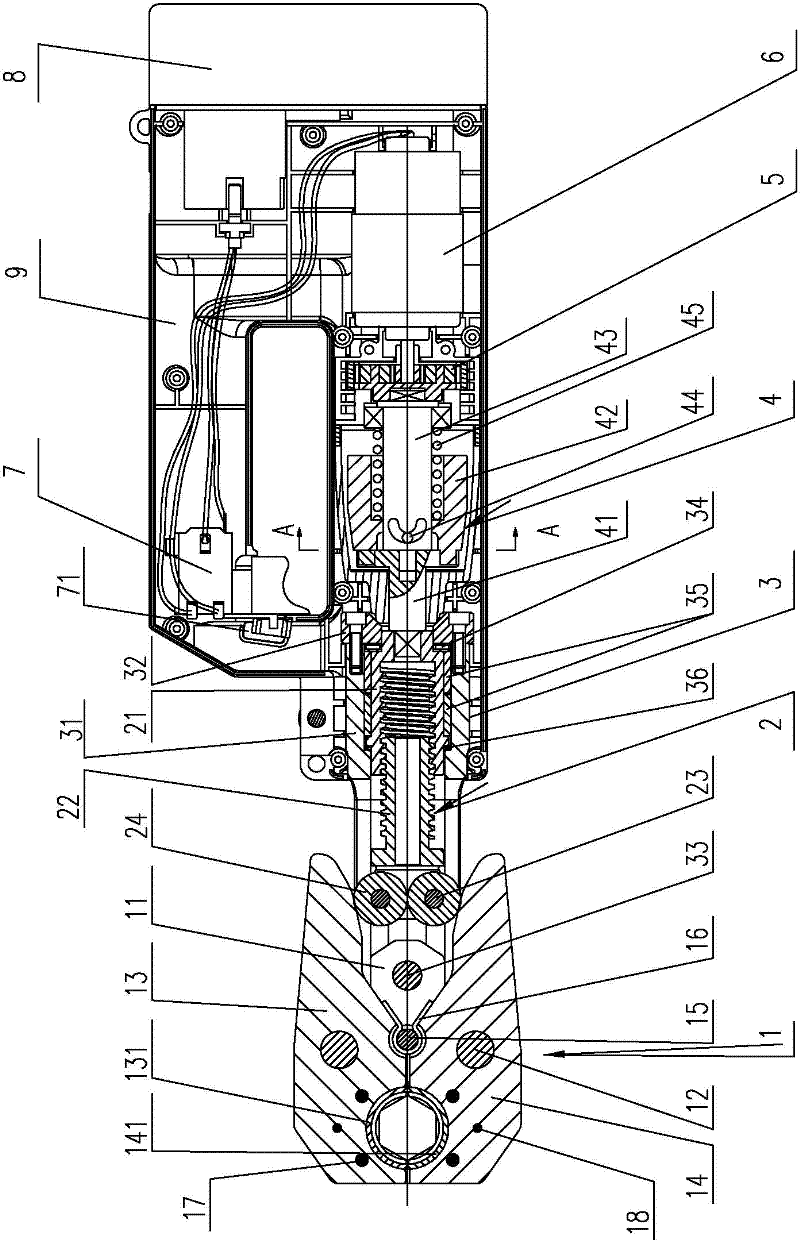

[0024] The present invention will be described in further detail below through specific examples.

[0025] An impact-type electric crimp or cutter, such as Figure 1 to Figure 7 As shown, it includes a housing 9 and a working head for crimping or shearing. A motor 6 and a reducer 5 are installed in the housing 9. The output shaft of the motor 6 is connected to the input shaft of the reducer 5. The output shaft of the reducer 5 drives the working head through the impact rotation assembly 4, the working head includes a sleeve 3, the sleeve 3 includes a sleeve body 31 and a rear cover 32, and the rear cover 32 is installed on the sleeve At the rear end of the barrel 3 , the rear cover 32 is provided with a hole, which is convenient for the output shaft 41 to be inserted and connected with the nut 21 of the lead screw nut mechanism 2 .

[0026] The front end of the sleeve 3 is installed with the jaw assembly 1 ; the rear end of the sleeve 3 is installed in the housing 9 and clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com