Lifting appliance

A lifting device and lifting iron technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems that the hole-shaft type body lifting structure cannot be used, the space of the fuel tank cover is tight, and the lifting device is large in volume, etc., and the structure is achieved. Compact, scientific and reasonable design, strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

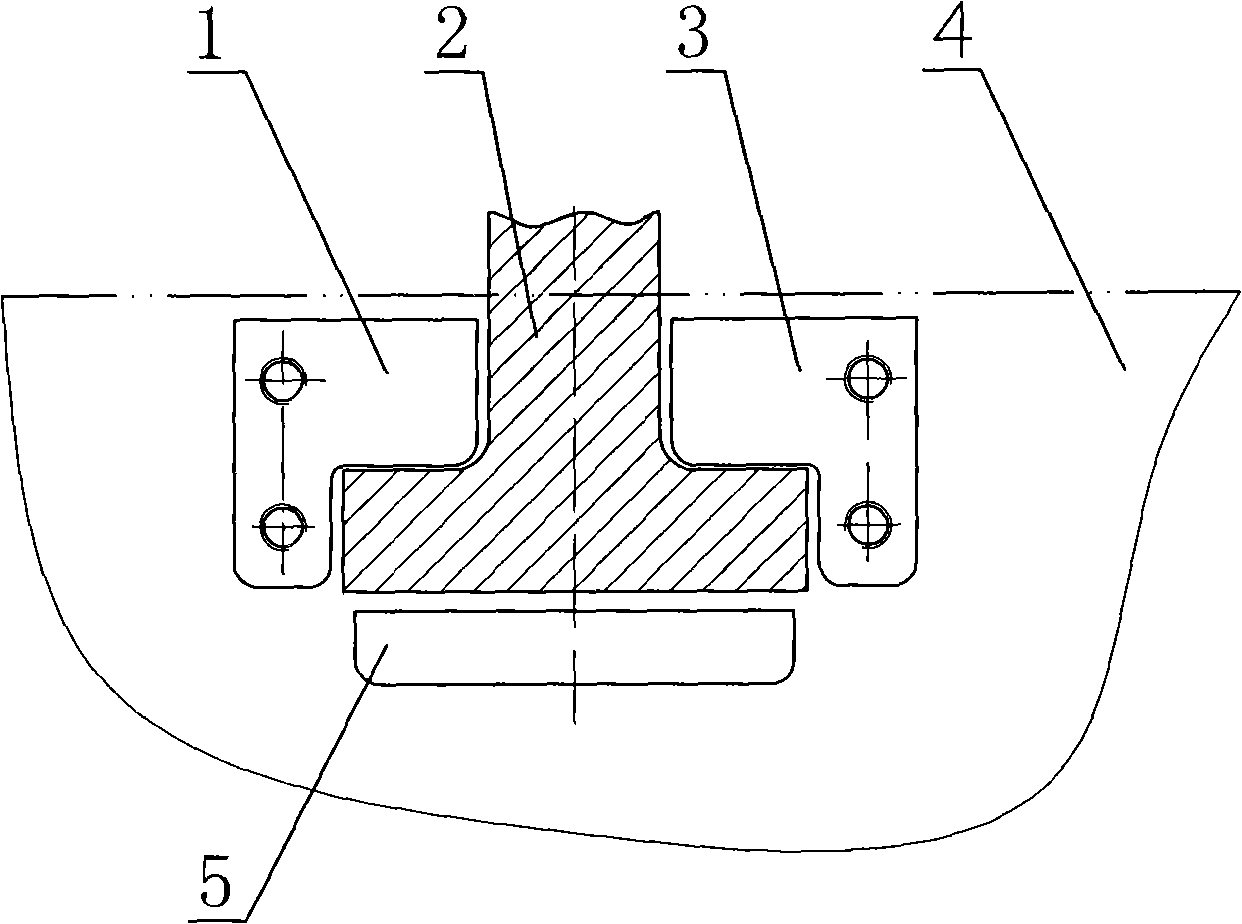

[0010] A hoisting device, including a web fixing part, a T-shaped hanging iron 2 and a cover plate, such as figure 1 There are three web fasteners shown, two L-shaped web fasteners 1, 3 and a one-shaped web fastener 5, two L-shaped web fasteners 1, 3 and one-shaped web fasteners The pieces 5 are welded to the web 4 of the object to be hung at intervals and enclose an inverted T-shaped area. The T-shaped hanging iron 2 is inverted in the inverted T-shaped area, and the upper end of the inverted T-shaped hanging iron 2 is extended out of the T-shaped area. The cover plate is fixed on the web fixing parts 1 and 3 by bolts. The T-shaped hanging iron 2 is located in the inverted T-shaped space formed by the cover plate and the web fixing member, and will not fall off, and the T-shaped hanging iron 2 can be lifted by lifting equipment to lift the object to be lifted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com