On-load switch hanger of transformer

A technology for transformers and switches, applied in the field of transformer on-load switch spreaders, can solve the problems of inability to lift the switch oil chamber, cumbersome switch assembly, and damage to the switch, and achieve the effect of changing the conventional installation process, shortening the assembly time, and avoiding bumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

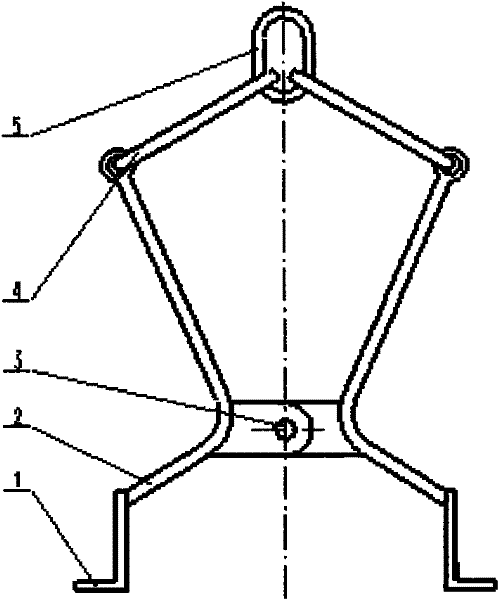

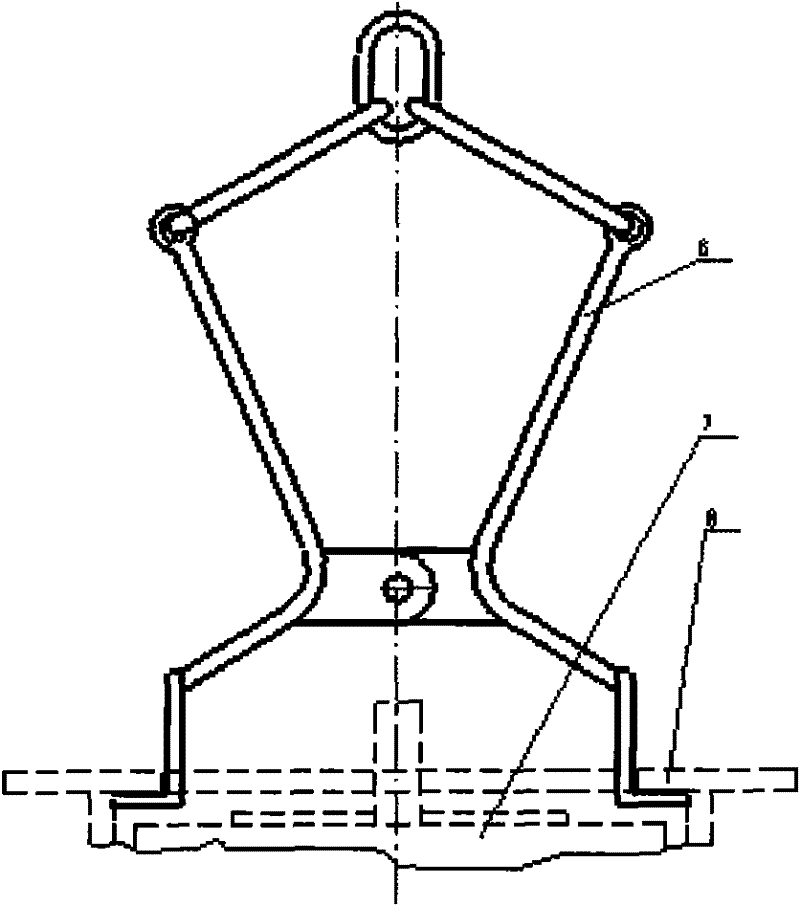

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

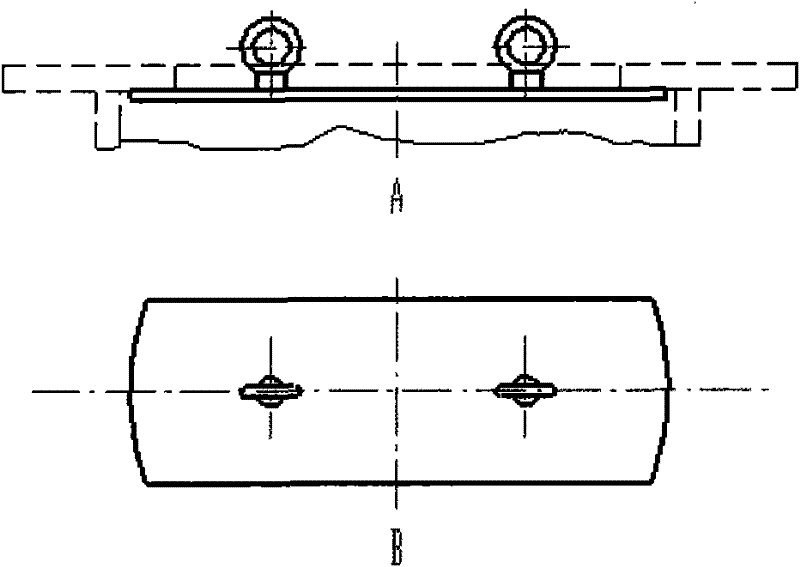

[0020] Such as figure 2 As shown, the transformer on-load switch hanger of the present invention includes a support foot 1, a connecting rod 2, a connecting member 4, and a lifting ring 5. The connecting rod 2 is two curved rods hinged at the bending position, each The lower ends of the connecting rods 2 are fixedly connected with supporting feet 1 respectively, and the stress surface of the supporting feet 1 is processed into a shape suitable for the bottom surface of the switch flange. The upper end is movably connected, and the other end is movably connected together with suspension ring 5.

[0021] Such as figure 2 As shown, the connecting rod 2 of the present invention is a V-shaped or L-shaped curved rod, and a plate can also be welded at the bending position of the connecting rod 2, and the two connecting rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com