Superposition type multi-point grease lubrication pump

A grease-lubricated, superimposed technology, applied in the direction of lubricating pumps, engine lubrication, engine components, etc., to achieve the effect of strong practicability, simple structure, and strong manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

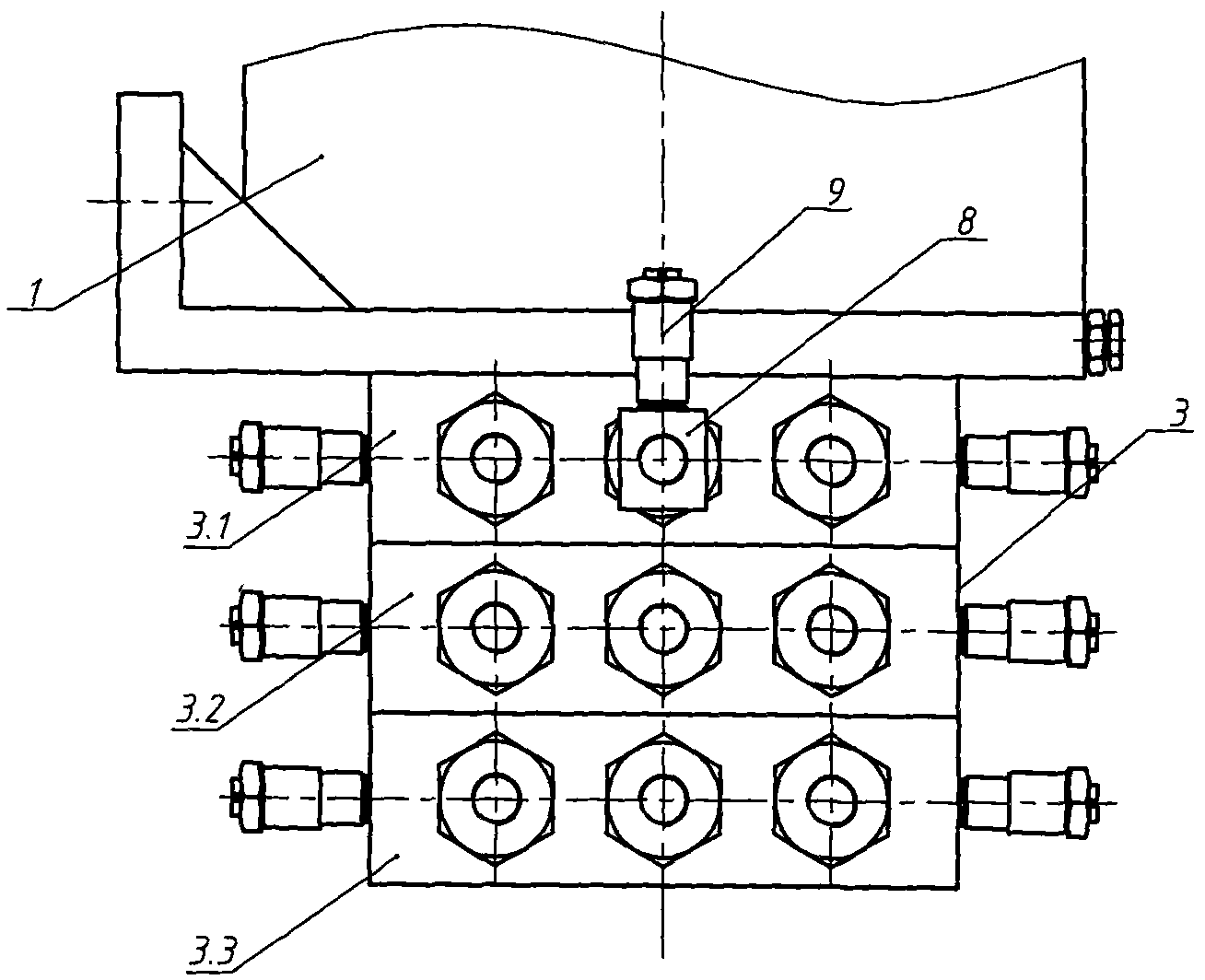

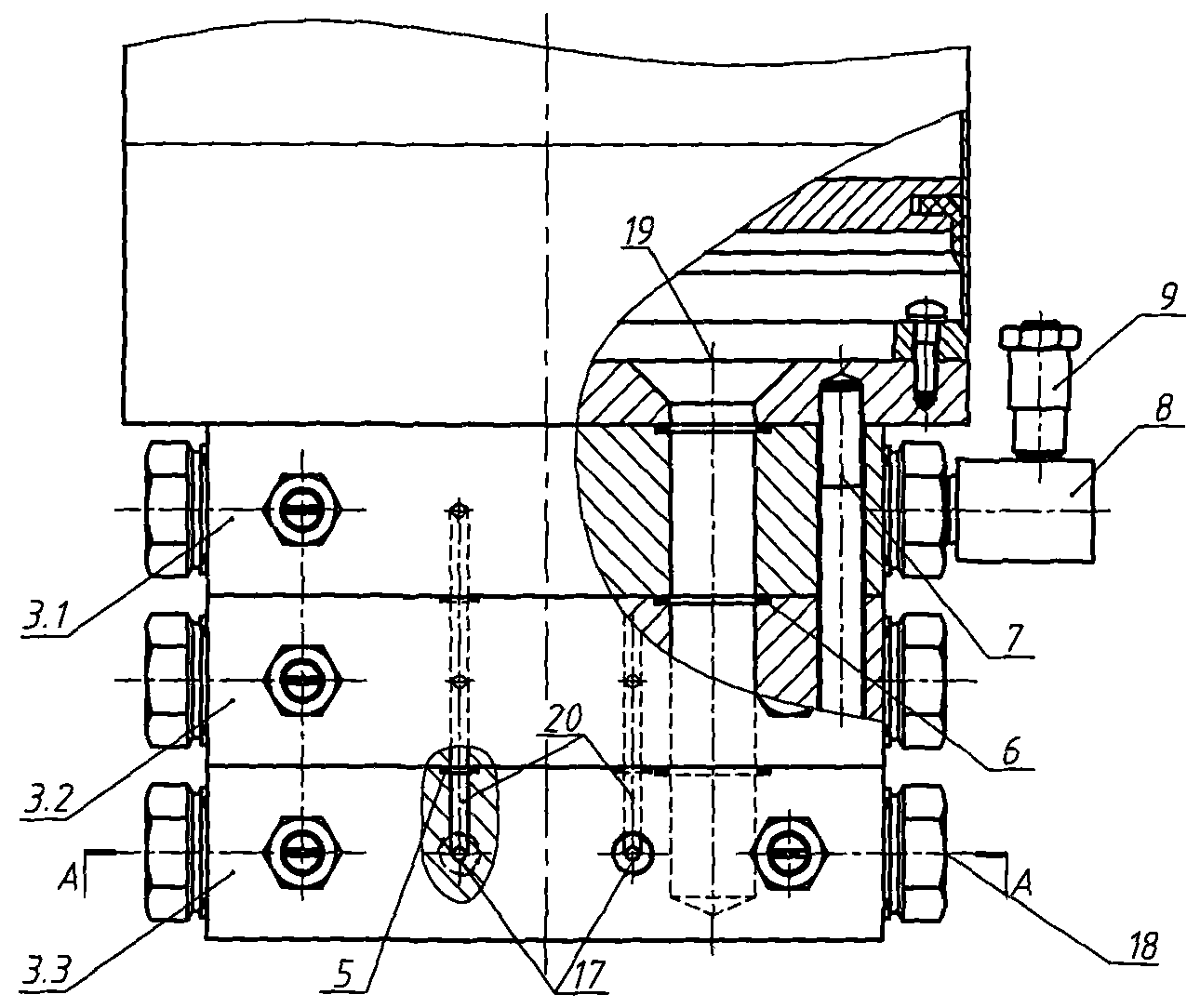

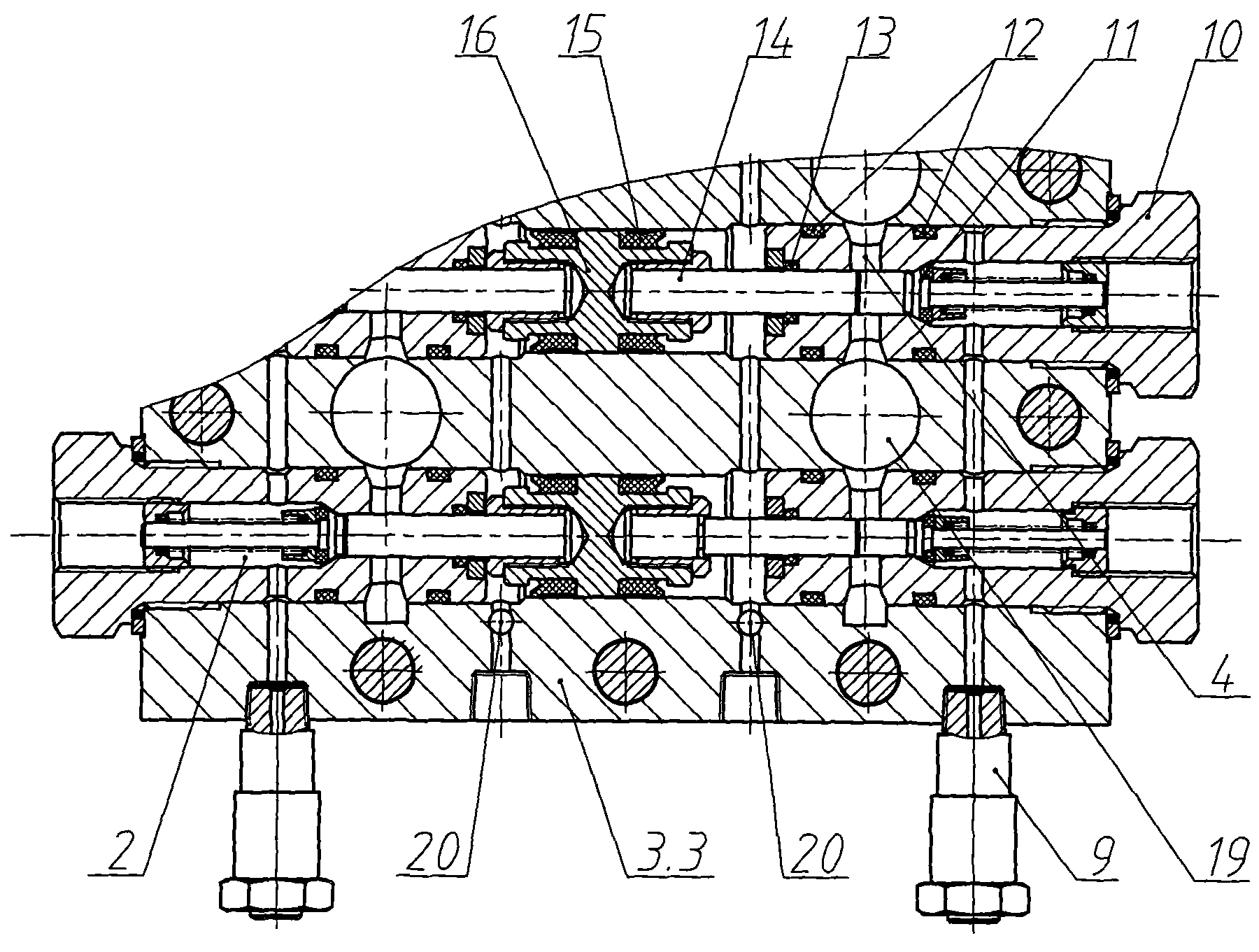

[0012] Such as figure 1 , figure 2 , image 3 The illustrated embodiment includes an oil storage tube 1, the bottom surface of the oil storage tube 1 is installed with a superimposed body assembly 3 composed of three bodies 3.1, 3.2, 3.3 through bolts 7, and each body 3.1, 3.2, 3.3 is Several sub-pumps are arranged in parallel, and the stacked body assembly 3 is provided with several public oil suction channel holes 19 and two common power source channel holes 20 connected to the power source. The common oil suction channel hole 19 communicates with the inner cavity of the oil storage cylinder 1, the common power source channel hole 20 communicates with the screw hole 17 of the external power source located on the lowermost body 3.3, and each body 3.1, 3.2, 3.3 The planes between the common oil suction channel hole 19 and the common power source channel hole 20 are sealed by O-rings 5 and 6 respectively. The number and combination of the bodies and the setting of the pub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com