Rolling friction or suspension friction impact mining method and wear-resistant impact mining machine using said method

a mining method and friction technology, applied in the direction of mining structures, slitting machines, surface mining, etc., can solve the problems of shortening the service life of equipment, heavy damage to the rotating shaft, and the crushing efficiency of drilling milling or milling cutting mining methods is relatively high with extremely high energy consumption, so as to improve the resistance of mining machines and reduce the damage of the impact guiding element. , the effect of high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

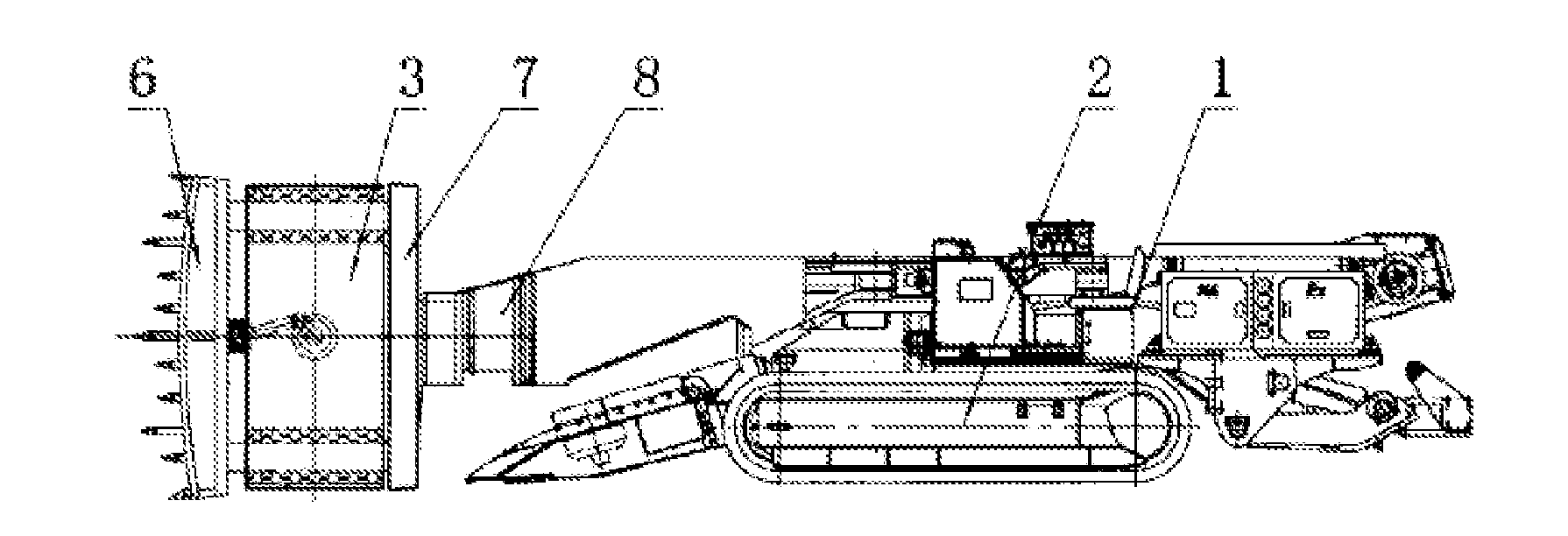

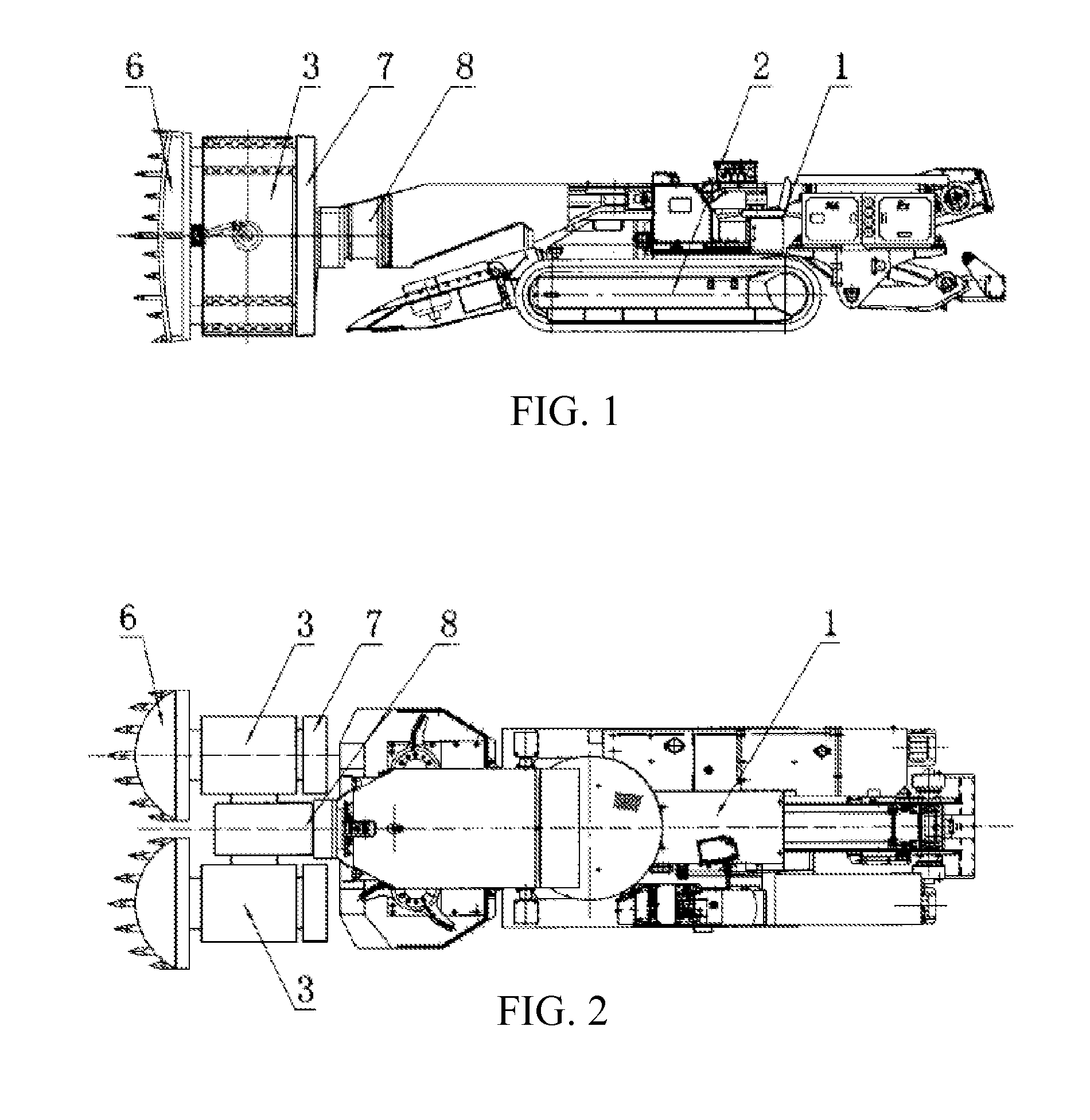

[0297]As shown in FIG. 1 to FIG. 3, a wear-resistant impact mining machine, the rolling friction impact mining machine comprises a machine body 1, a travelling part 2, and a reciprocating impact part 3 etc.; the reciprocating impact part 3 comprises a guiding device 5 and an impact drive device 4 etc.; the guiding device 5 and the impact drive device 4 are separated; the guiding device 5 comprises an impact guiding element 5.1, guiding rollers 5.3 and a guiding support 5.2 etc.; the guiding rollers 5.3 are provided between the guiding support 5.2 and the impact guiding element 5.1; one end of the impact guiding element 5.1 is provided with an impact head 6 and the other end is provided with a counterweight element 7 for preventing the impact head 6 from damaging the guiding device 5, the impact drive device 4 and / or the machine body 1 etc. due to gravity unbalance; the impact head 6 is connected with the impact guiding element 5.1; the impact drive device 4 comprises a power impact ...

embodiment 2

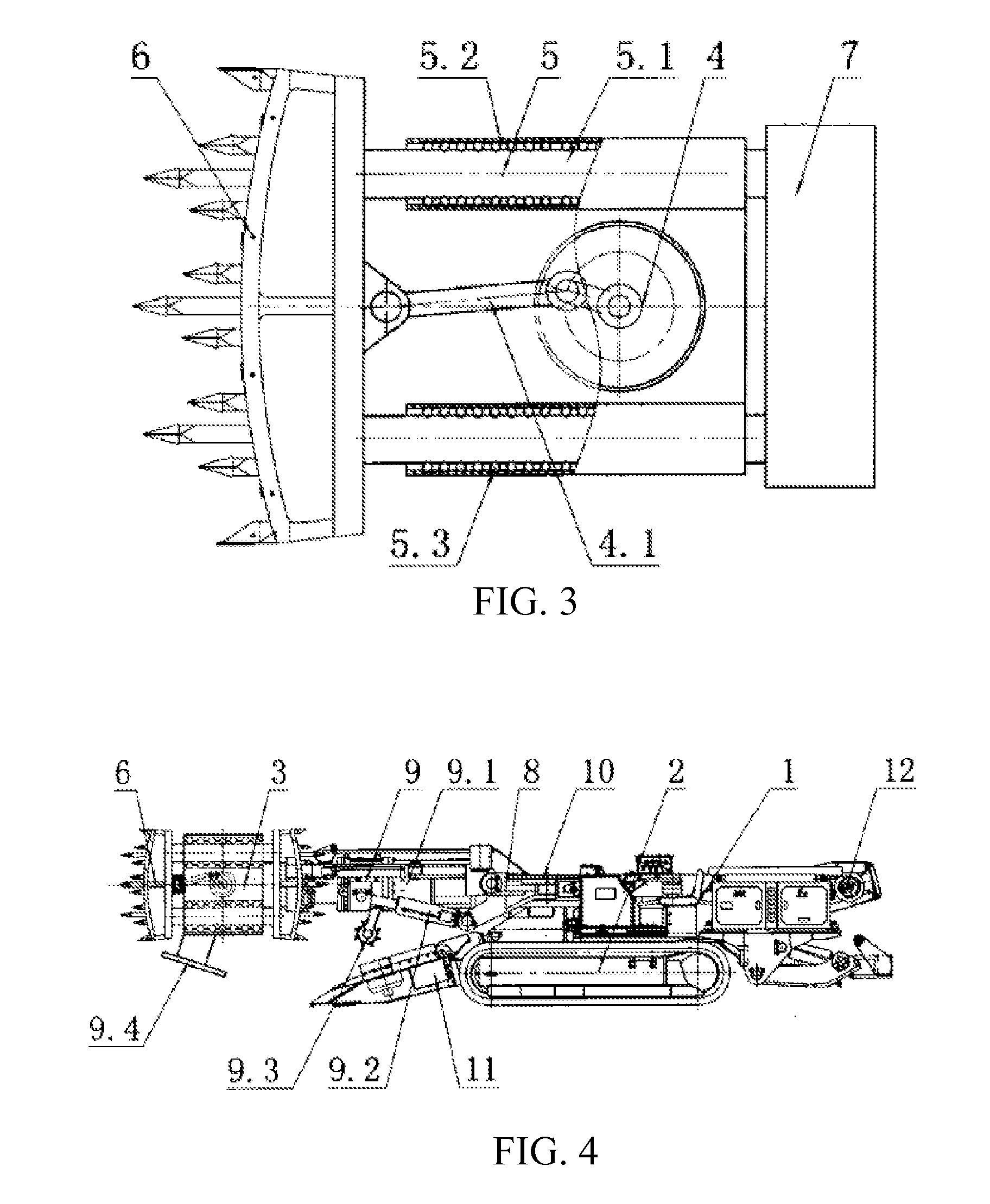

[0311]As shown in FIG. 4 to FIG. 5, a wear-resistant impact mining machine, the rolling friction impact mining machine comprises a machine body 1, a travelling part 2, and a reciprocating impact part 3 etc.; the reciprocating impact part 3 comprises a guiding device 5 and an impact drive device 4 etc.; the guiding device 5 and the impact drive device 4 are integrated; the guiding device 5 comprises an impact guiding element 5.1, guiding rollers 5.3 and a guiding support 5.2 etc.; the guiding rollers 5.3 are provided between the guiding support 5.2 and the impact guiding element 5.1; two ends of the impact guiding element 5.1 are provided with impact heads 6 etc.; the impact heads 6 and the impact guiding element 5.1 are integrated; the impact drive device 4 comprises a power impact element 4.1 etc.; the power impact element 4.1 drives the impact guiding element 5.1 to reciprocate; the impact guiding element 5.1 drives the impact heads 6 to impact a coal wall or a rock wall to fall a...

embodiment 3

[0322]As shown in FIG. 6 to FIG. 7, a wear-resistant impact mining machine comprises a machine body 1, a travelling part 2, a jacking device 9 and a reciprocating impact part 3 etc.; the reciprocating impact part 3 comprises a guiding device 5 and an impact drive device 4 etc.; the impact drive device 4 comprises a crank impact drive device 4.2 or a hydraulic impact drive device or a pneumatic impact drive device etc.; the crank impact drive device 4.2 or the hydraulic impact drive device or the pneumatic impact drive device comprises a power impact element 4.1 etc.; the guiding device 5 comprises a guiding support 5.2, an impact guiding element 5.1 and guiding rollers 5.3 etc.; the guiding rollers 5.3 are provided between the guiding support 5.2 and the impact guiding element 5.1; one end of the impact guiding element 5.1 is provided with an impact head 6 and the other end is provided with a counterweight element 7 for preventing the impact head 6 from damaging the guiding device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com