Laser combined welding head regulating mechanism

A technology of composite welding and adjustment mechanism, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of unable to adjust the relative position, unable to combine welding process, narrow application range, etc., to achieve convenient production, reasonable structure, expansion The effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

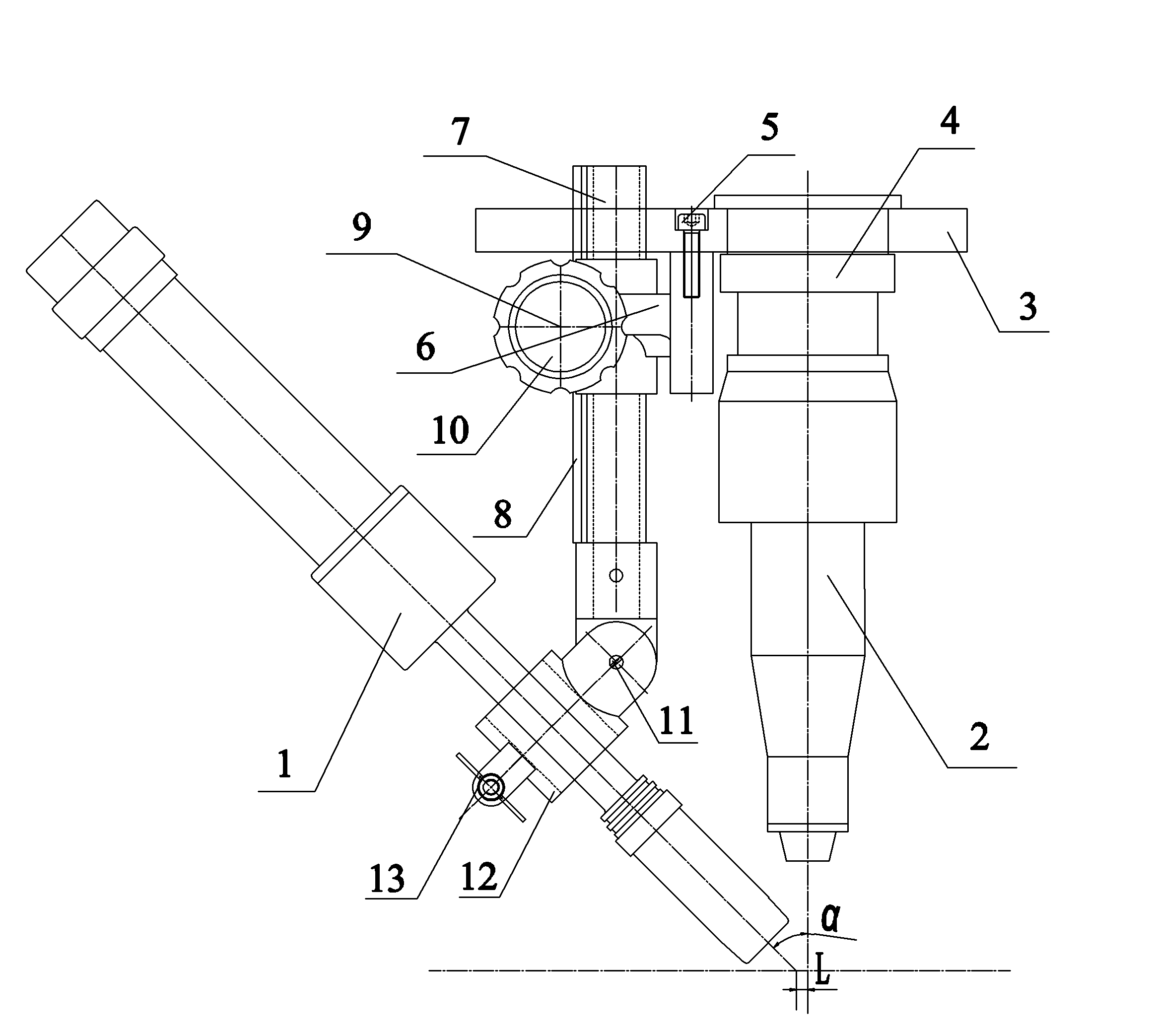

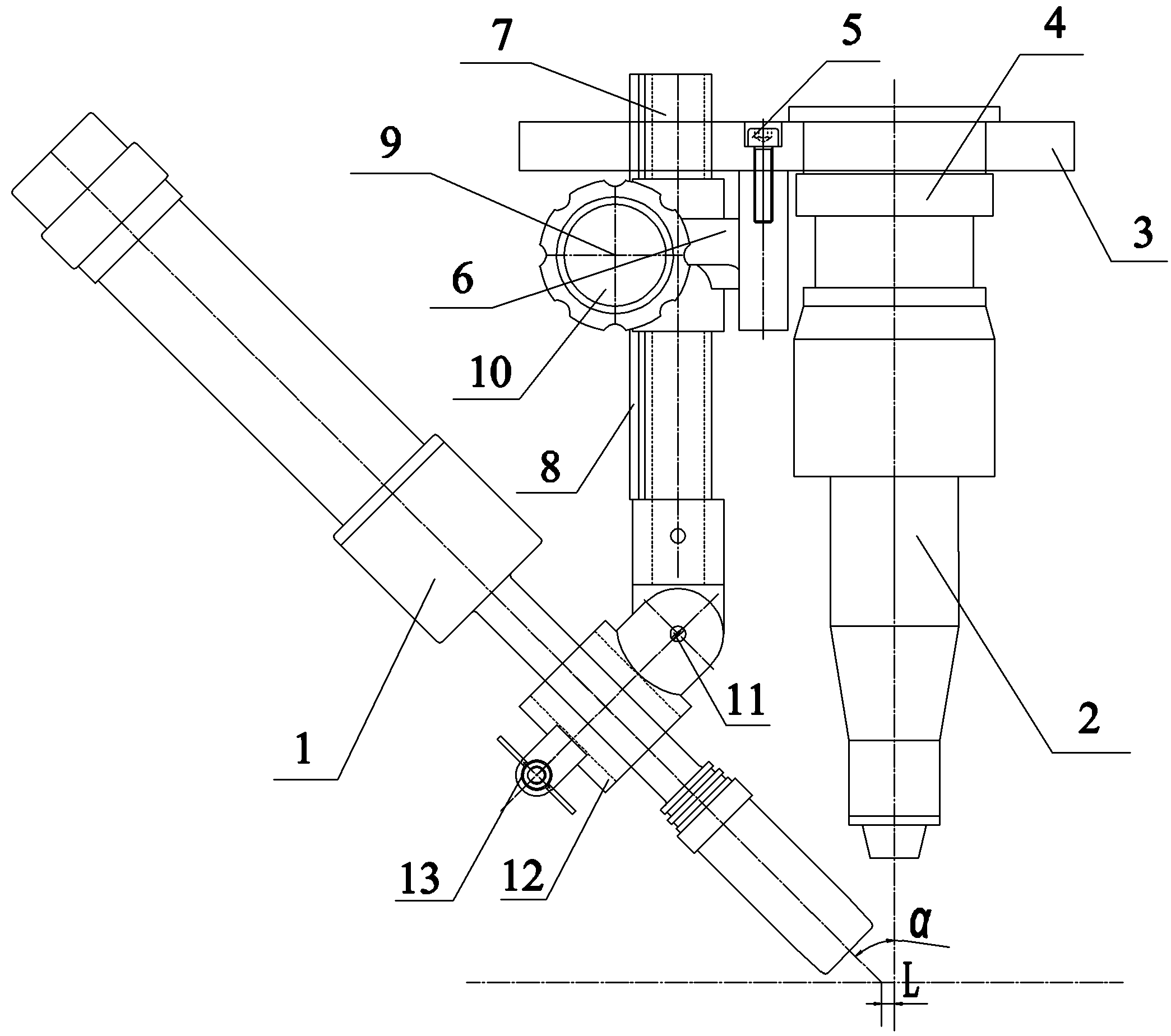

[0011] Such as figure 1 As shown, it includes welding gun 1, laser head 2, aluminum alloy plate 3, screw sleeve 4, screw 5, sleeve seat 6, guide post 7, rack 8, gear 9, knob 10, first wing nut 11, clip Set 12 and the second wing nut 13.

[0012] The present invention first installs the spiral sleeve 4 in the hole of the aluminum alloy plate 3, the laser head 2 is installed on the spiral sleeve 4, the sleeve seat 6 is fixed on the aluminum alloy plate 3 by the screw 5, and the guide post 7 and the rack 8 are installed on the aluminum alloy plate 3. In the sleeve of the sleeve seat 6, the gear 9 is embedded on the knob 10, the jacket 12 is connected with the guide post through the first wing nut 11, and the welding torch 1 is installed on the jacket 12 and fixed by the second wing nut 13.

[0013] Working process and working principle of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com