Grinding wheel numerically-controlled finishing control device and control method special for face gear grinding

A control device and face gear technology, applied in the direction of digital control, abrasive surface adjustment device, electrical program control, etc., can solve the problems of large grinding contact area, high manufacturing precision requirements for diamond rollers, complex profile, etc., and reduce the installation time. Precision requirements, ease of maintenance and use, effect of reduced cooling requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

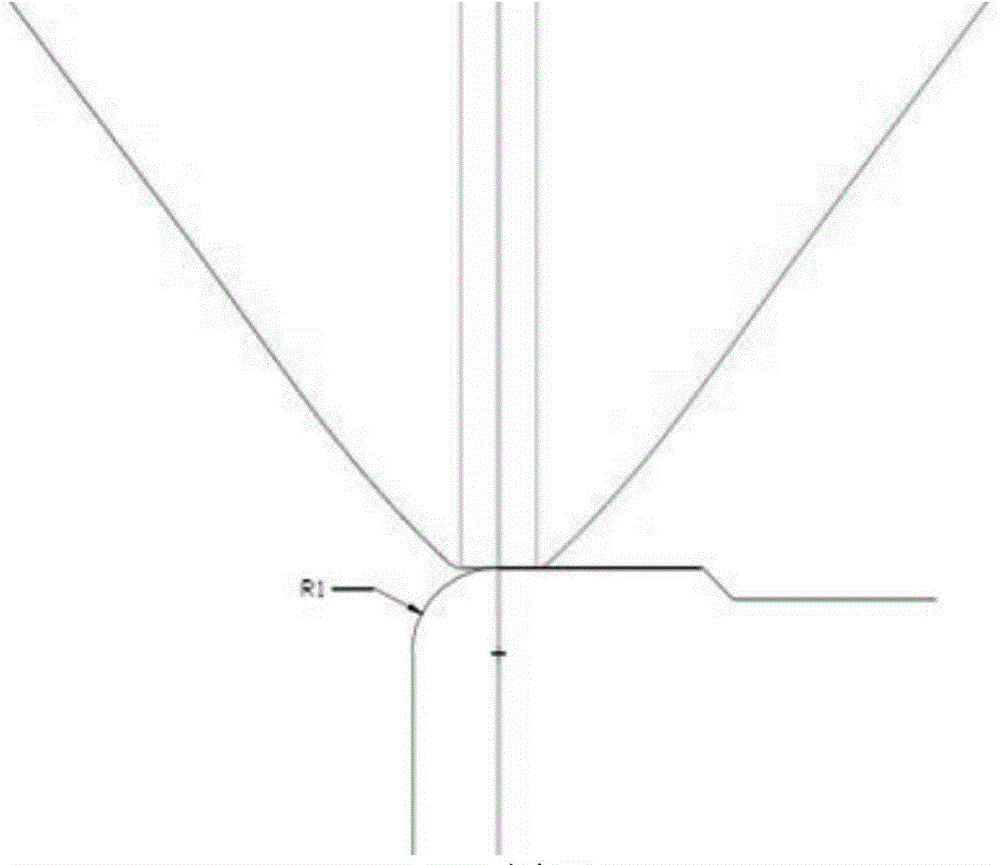

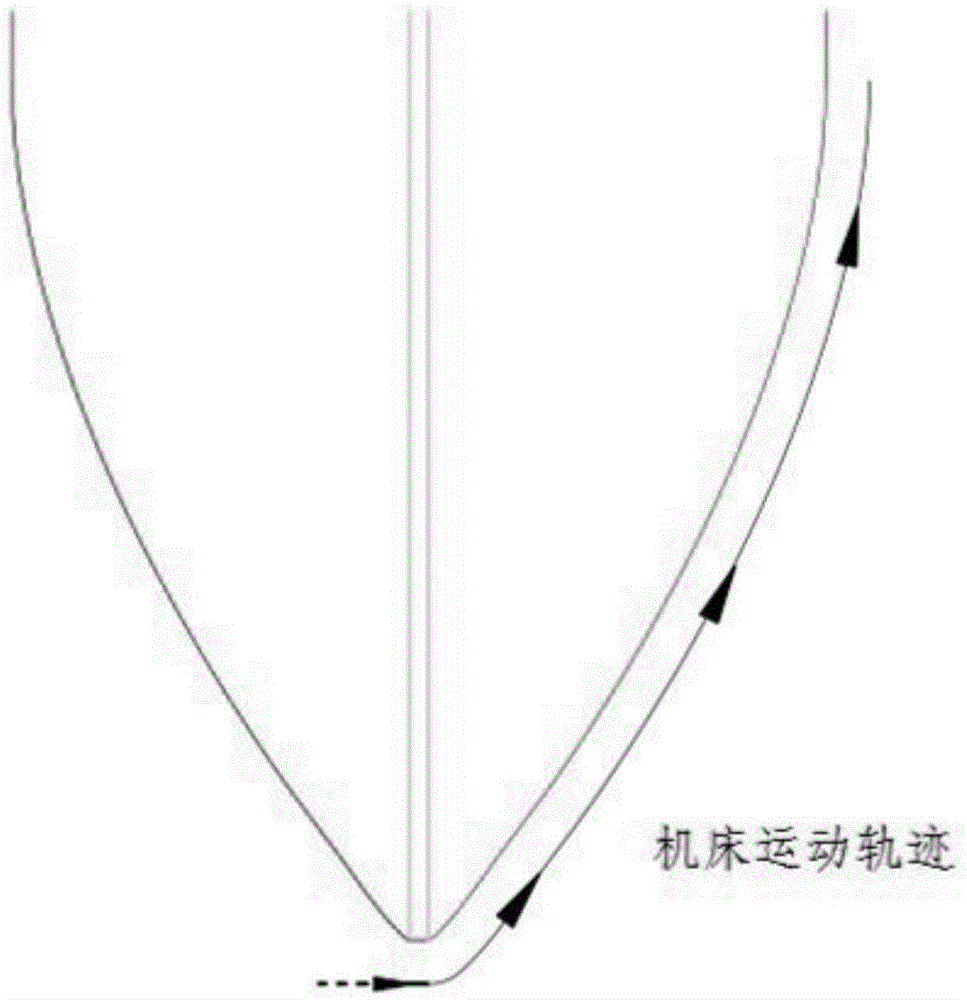

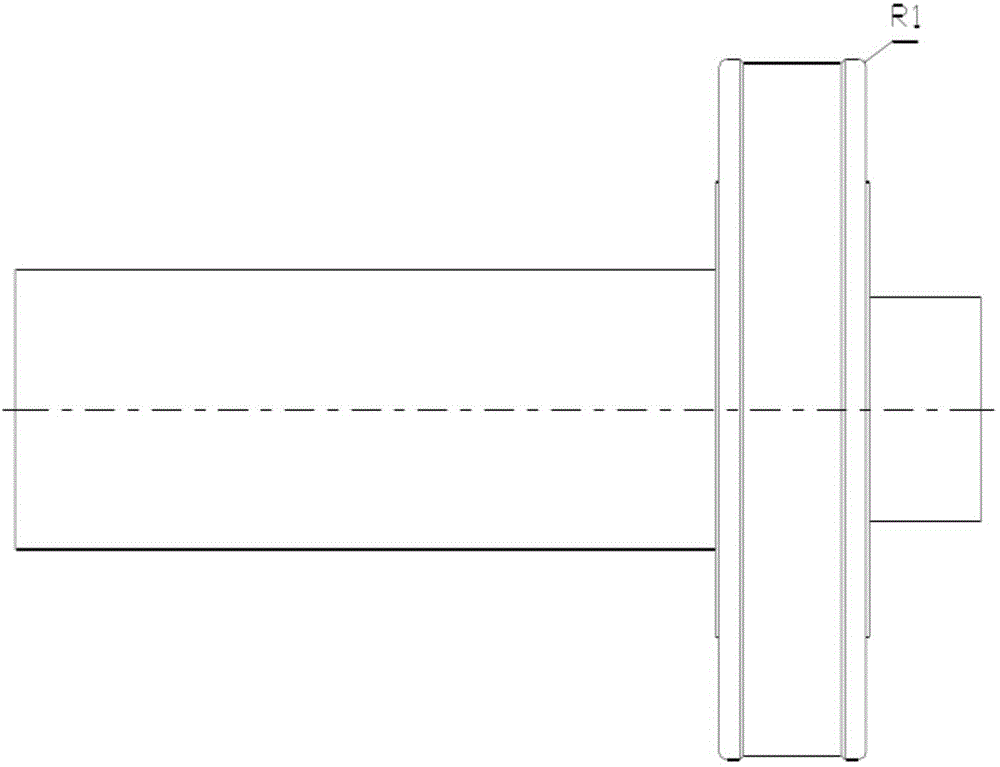

[0039] The schematic diagram of the shape of the diamond roller is shown in figure 1 , the part used for trimming and cutting is the fillet of R1. The principle of trimming involute profile grinding wheel by offset curve method is as follows: figure 2 As shown, the cross-sectional shape of the special grinding wheel for face gear grinding is convex involute shape. Since the face gear grinding process uses one side of the grinding wheel for processing, only the worn side of the grinding wheel is needed for each dressing. Use the software to parametrically model the involute to be trimmed, and make a 1mm outer offset curve on the side to be trimmed, and take a series of points on the offset curve according to the accuracy requirements to pass through these broken lines As the movement trajectory during trimming, the coordinate data of these points is obtained through the software, and the relative coordinates between each two points are calculated, so as to obtain the G code o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com