Multiaxial motion servocontrol and protection system

A servo control, multi-axis motion technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of high cost of hardware equipment, inability to timely feedback the operating status of the actuator, and inability to meet special control requirements, etc. The effect of improving real-time and scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A multi-axis motion servo control and protection system based on an ARM processor of the present invention is a multi-axis servo control device used in various automation equipment motion mechanisms and a motion protection device for actuators such as overload and limit. The system can realize the position and speed linkage servo control of up to 8 motion axes at the same time, and can detect the running status of each axis in real time, so as to ensure that the mechanism and motor will not be damaged due to mechanical limit, overload and overcurrent from the hardware circuit. cause damage and increase the security of the system.

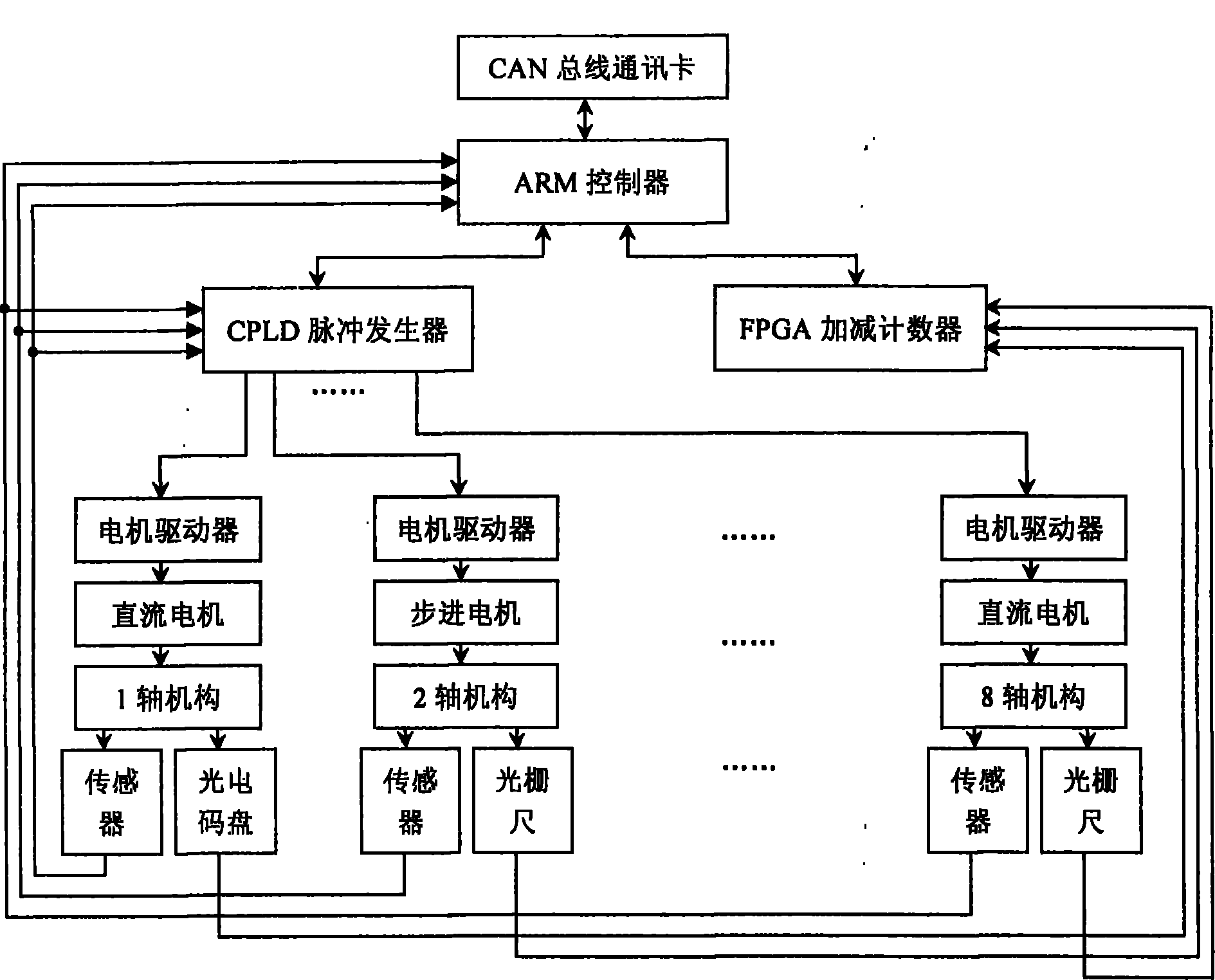

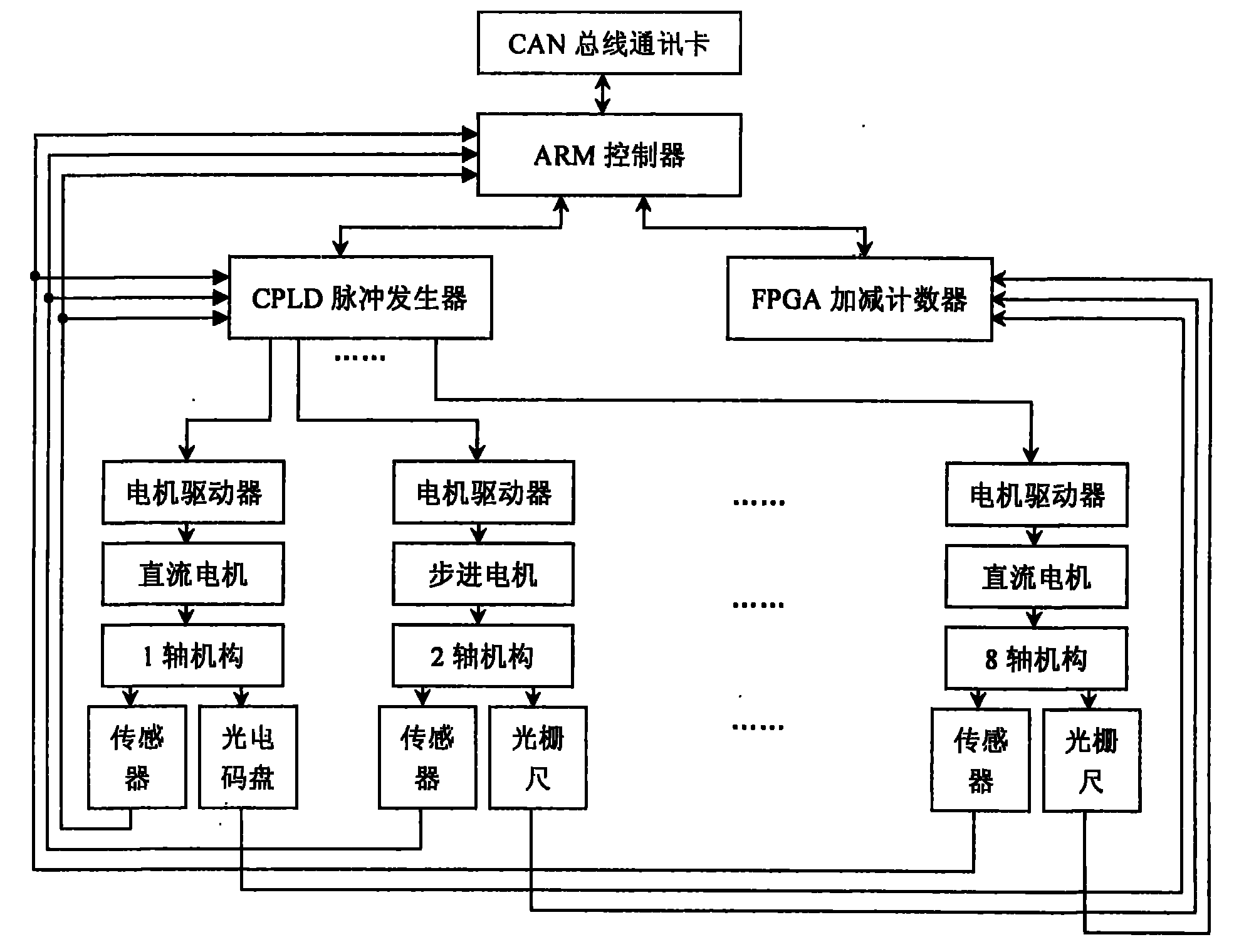

[0015] figure 1 It is a structural block diagram of a single multi-axis motion servo control and protection system, which is mainly composed of two parts: ARM control circuit and drive protection hardware. The ARM control circuit is the weak current control part of the system, which mainly realizes the implementation of the linkage control a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com