Rack and production method thereof

一种制造方法、齿条的技术,应用在带有齿的元件、皮带/链条/齿轮、便携式提升装置等方向,能够解决不理想、制造成本上升等问题,达到易于精度、抑制加工负荷、加工负荷抑制的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] [First example of embodiment]

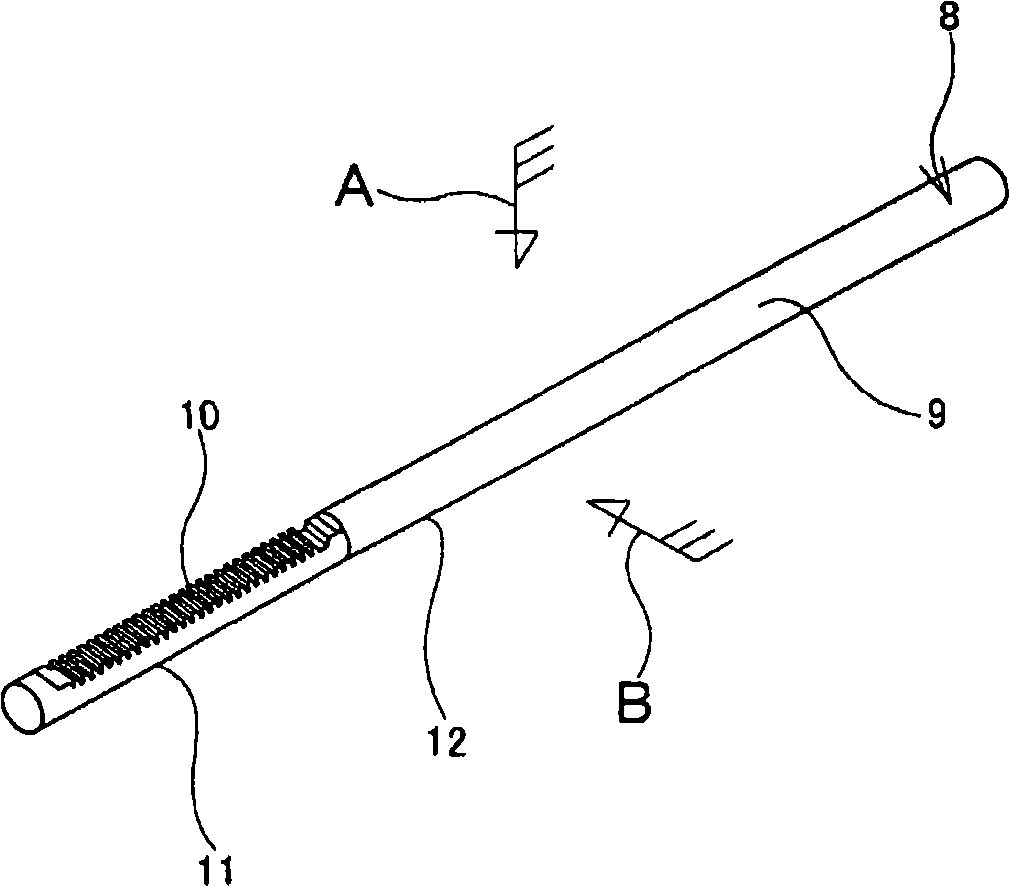

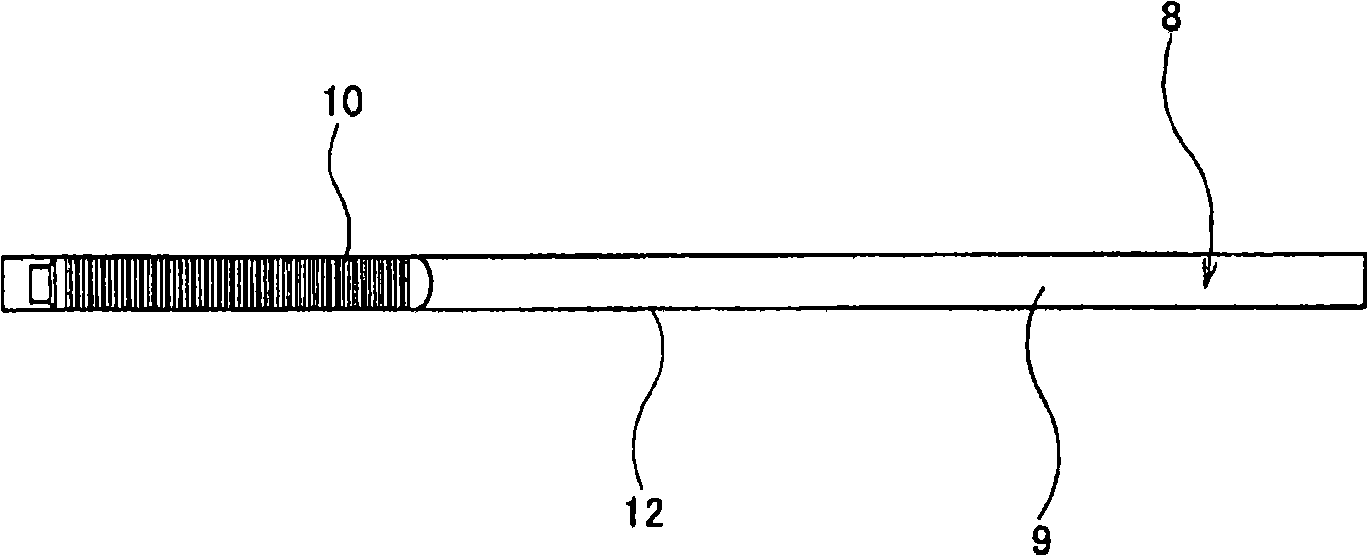

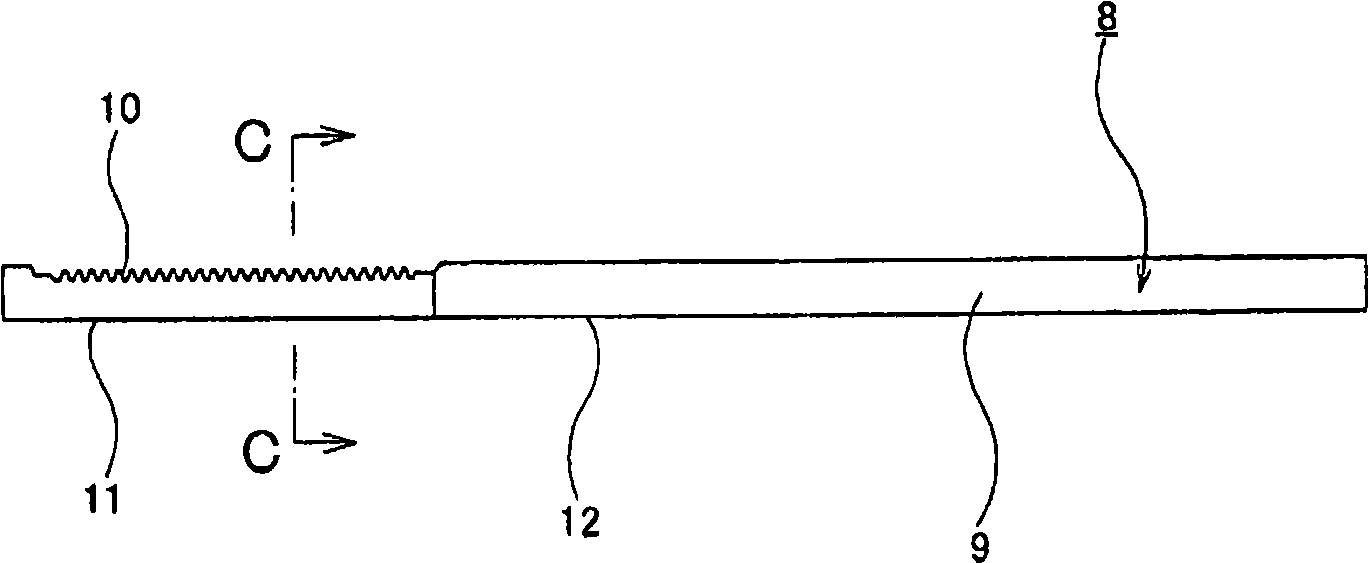

[0095] Figure 1~8 This shows the first example of the embodiment of the present invention. First, use Figure 1~4 The structure of the rack 8 of this example will be described. In addition, in the following description, the radius of curvature of each surface refers to the radius of curvature of the cross-sectional shape of each surface unless otherwise specified.

[0096] The rack 8 is made of a metal material such as carbon steel, stainless steel, etc., and has a rod 9 with a circular cross-section as a solid member, and a part of the rod 9 in the axial direction ( Figure 1~3 (Left part) of the rack teeth 10 formed by plastic working on the radial single side surface. In the case of this example, the above-mentioned rod portion 9 is integrally made of the same metal material from the outer peripheral surface to the center portion over the entire length. In addition, in a portion of the rod portion 9 in the axial direction, the radius of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com