Laser encoder, displacement measurement method of using the laser encoder, and fabricating method of numerically controlled machine

A technology for encoders and laser light sources, which is applied in the direction of transmitting sensing components, measuring devices, instruments, etc. by using optical devices, and can solve problems such as failure to reach and lower resolution of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

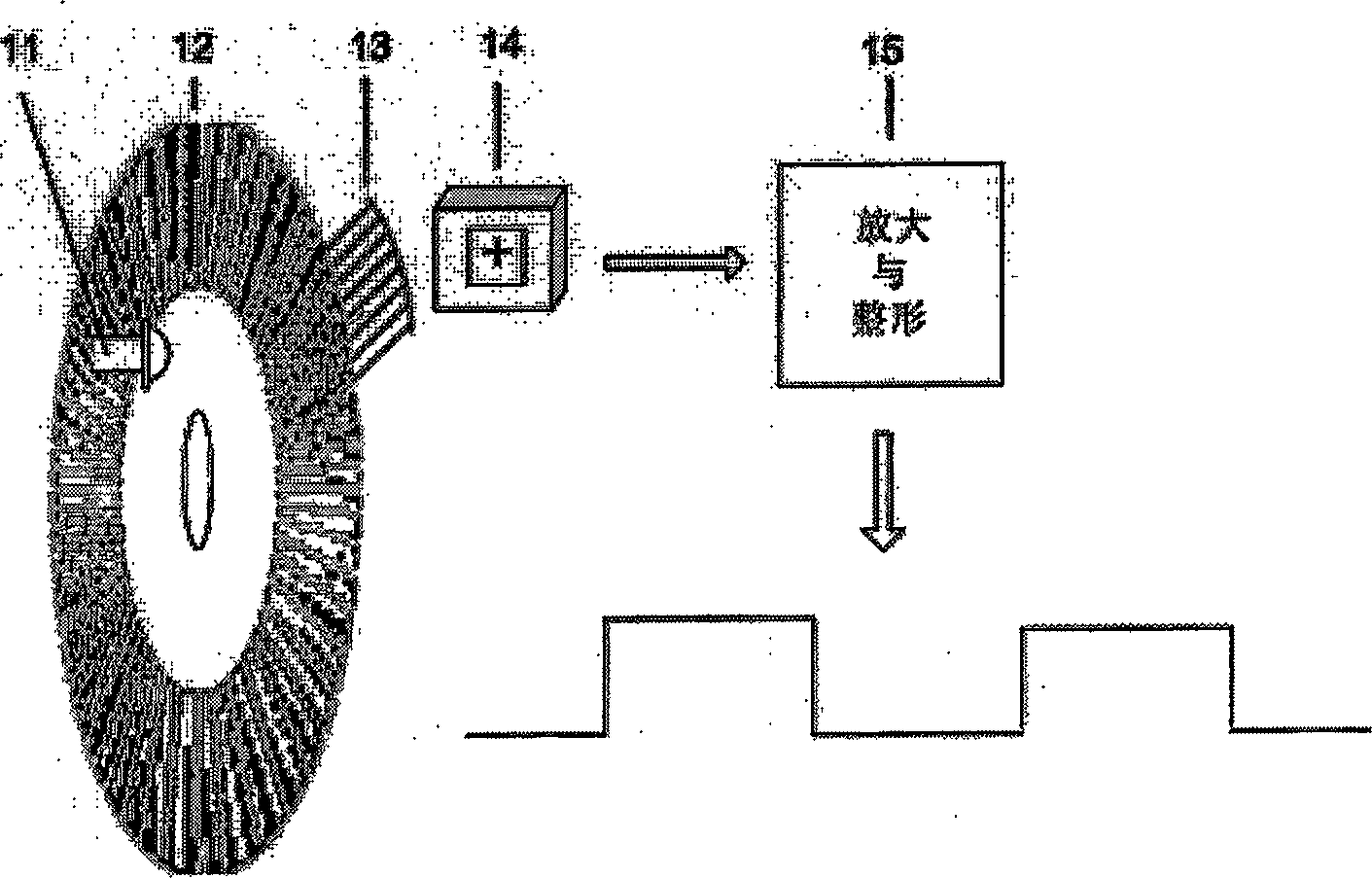

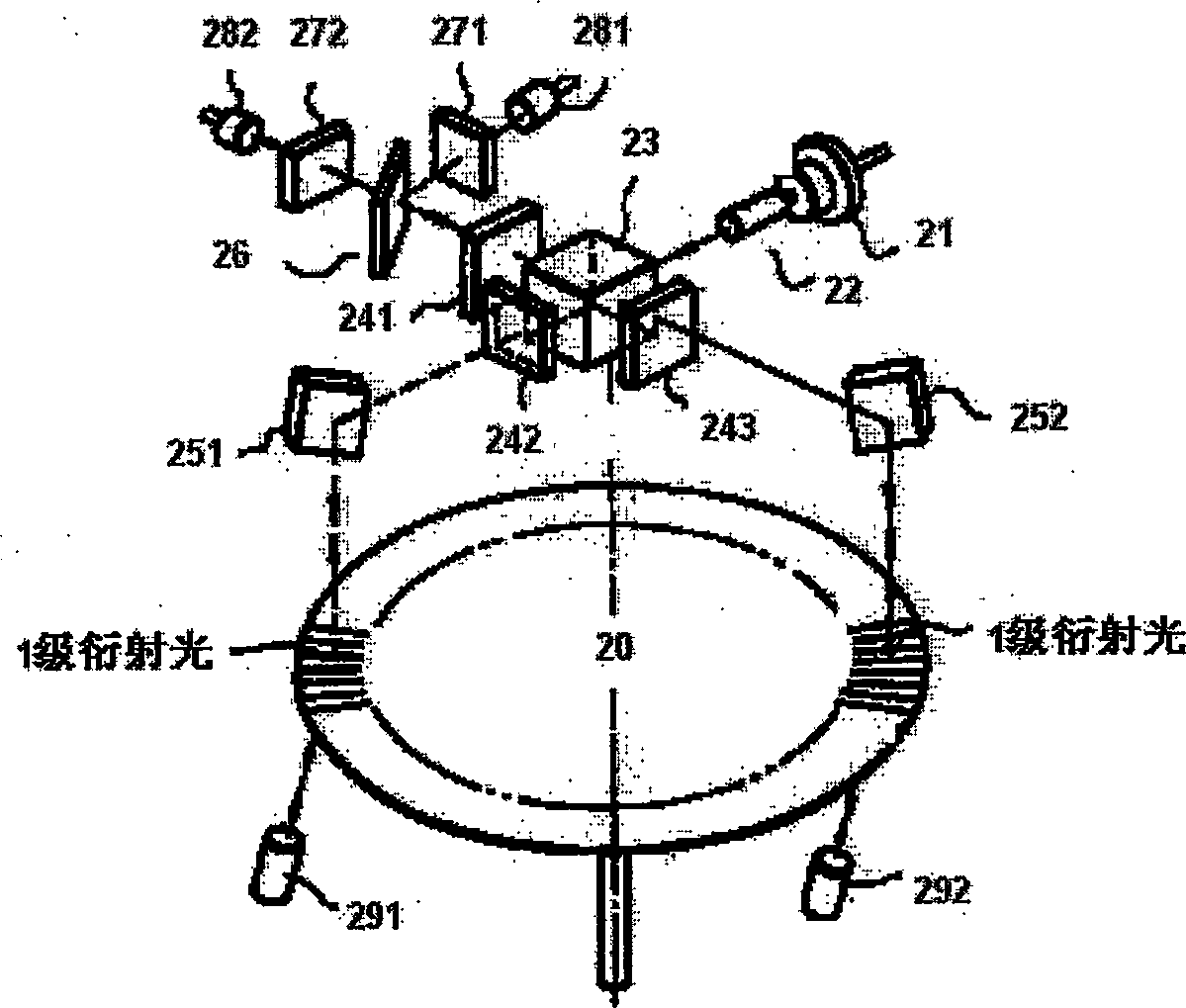

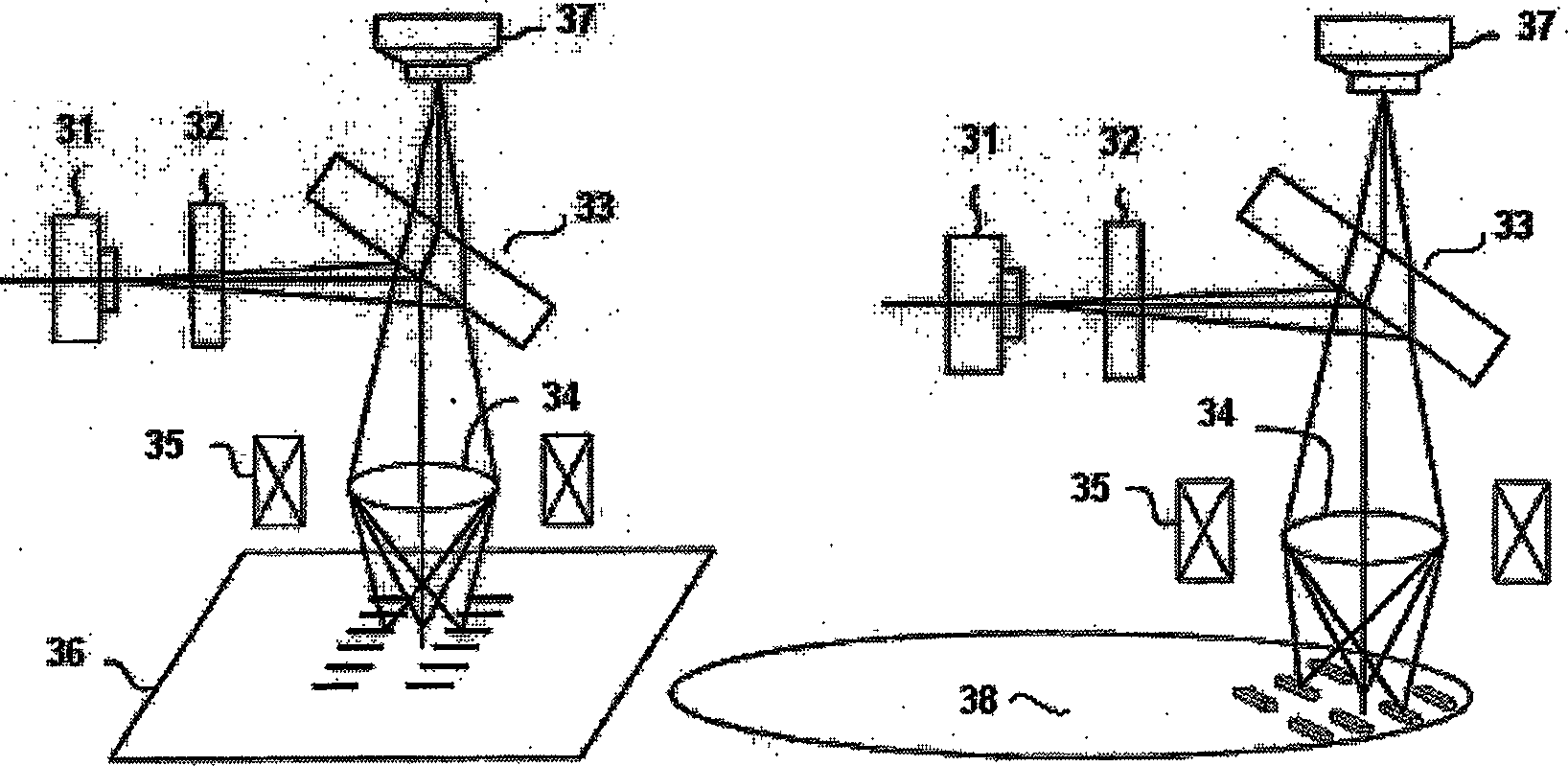

[0077] Figure 1 to Figure 3 Accordingly, some aspects of the background technology of the present invention are introduced; Figure 4 to Figure 11 Various aspects of the devices and methods of the present invention are presented.

[0078] Figure 4 The optical path of the laser encoder of the present invention is shown. In the figure, numeral 1 denotes a laser light source, 2 denotes a diffraction grating, 3 denotes a polarization beam splitter, 4 denotes a collimator lens, 5 denotes a 1 / 4 wave plate, 6 denotes an objective lens, and 7 denotes a code disk , 8 represents a concave lens, 9 represents a cylindrical lens, 10 represents a photodiode array, 7A represents a tracking coil, and 7B represents a focusing coil. As shown in the figure, the light from the diffraction grating (2) is focused on the code disc 7 after passing through the polarization splitter prism 3, the collimating lens 4, the 1 / 4 wave plate 5 and the objective lens 6, and is reflected from the code disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com