Synchronous cold/thermal response ground thermal property tester

A technology of thermal response and cold response, applied in the direction of material thermal development, etc., can solve the problems of difficult to achieve constant heat flow conditions, influence of test results, wrong conclusions, etc., to reduce test costs, solve errors, and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

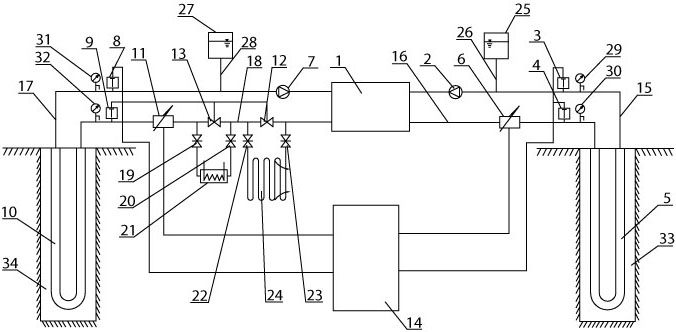

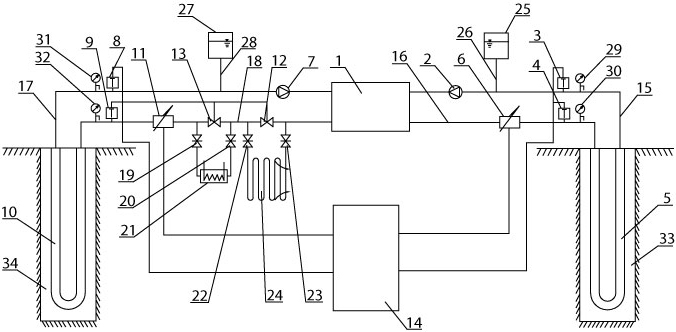

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment. This embodiment includes a water-water heat pump unit 1, a cold response side circulation pump 2, a cold response side return water temperature sensor 3, a cold response side water supply temperature sensor 4, a cold response side U-shaped pipe 5, and a cold response side. Side flow meter 6, thermal response side circulation pump 7, thermal response side return water temperature sensor 8, thermal response side water supply temperature sensor 9, thermal response side U-shaped pipe 10, thermal response side flow meter 11, radiator regulating valve 12, Heater regulating valve 13, data acquisition device 14, cold response side return pipe 15, cold response side water supply pipe 16, heat response side return water pipe 17, heat response side water supply pipe 18, first heater gate valve 19, second heater Gate valve 20, electric heater 21, first radiator gate valve 22, second radiator gate valve 23 ...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment. The difference between this embodiment and the first embodiment is that it also adds a cold response side expansion tank 25, a cold response side water tank connection 26, a heat response side expansion tank 27, and a heat response side water tank connection 28. The cold response One end of the side water tank connection pipe 26 is connected to the cold response side return pipe 15, the other end of the cold response side water tank connection pipe 26 is connected to the cold response side expansion tank 25, and one end of the heat response side water tank connection pipe 28 is connected to the heat response side return pipe 17, The other end of the heat response side water tank connecting pipe 28 is connected with the heat response side expansion water tank 27 . The expansion tank can accommodate the expanded circulating medium in the instrument system and supplement the circulating medium...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1Describe this embodiment. The difference between this embodiment and the first embodiment is that it also adds a cold response side return pipe pressure gauge 29, a cold response side water supply pipe pressure gauge 30, a heat response side return pipe pressure gauge 31 and a heat response side. The water supply pipe pressure gauge 32 and the cold response side return pipe pressure gauge 29 are installed on the cold response side return pipe 15, and are located between the cold response side return water temperature sensor 3 and the cold response side U-shaped pipe 5, and the cold response side water supply pipe The pressure gauge 30 is installed on the cold response side water supply pipe 16, and is located between the cold response side water supply temperature sensor 4 and the cold response side U-shaped pipe 5, and the heat response side return pipe pressure gauge 31 is installed on the heat response side retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com