Light path device and method for laser peening forming of large workpiece

A technology of laser peening forming and large workpieces, which is applied in the field of laser peening optical path device and laser peening forming, which can solve the problems of complex motion mechanism, difficult motion accuracy and not simple structure of the universal joint reflector, and reach the range of motion Small, simple movement, small space occupation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

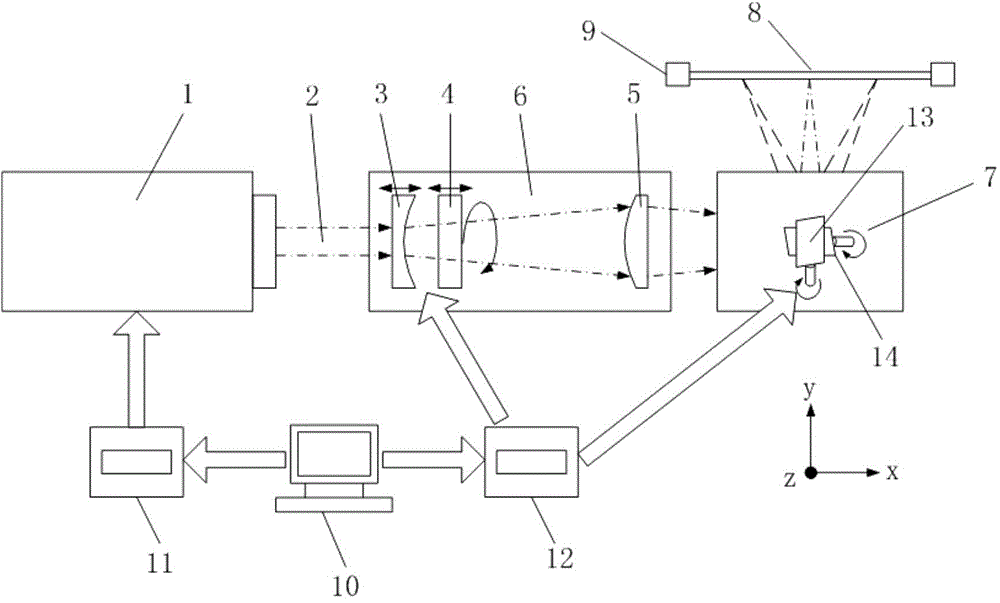

[0038] The workflow of the embodiment is as follows:

[0039] (1) First, the shot peening route is input on the computer 10 . At a certain moment in the scanning process, the coordinates of the scanning position on the forming workpiece 8 at this moment are determined according to the process path;

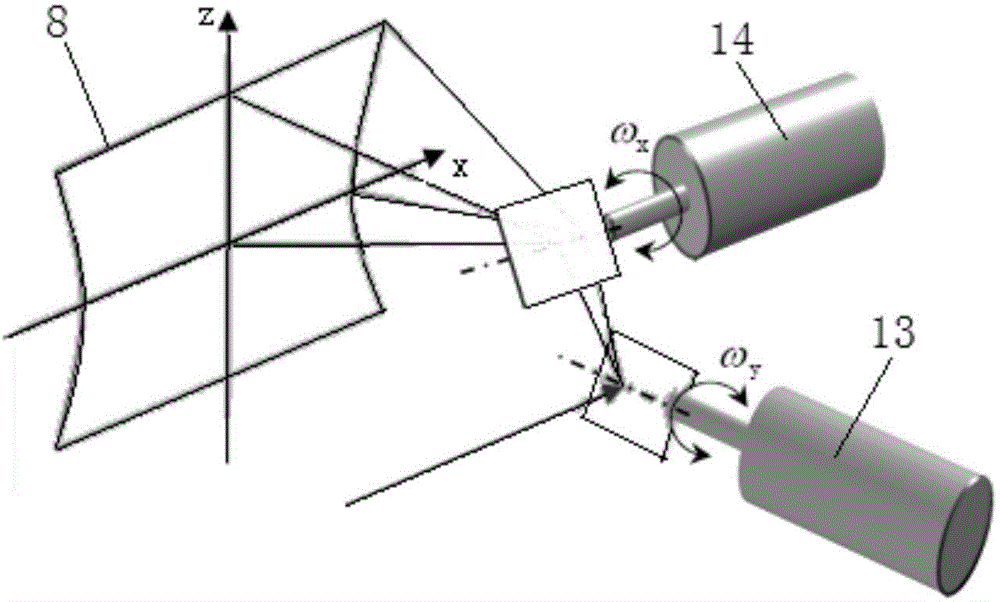

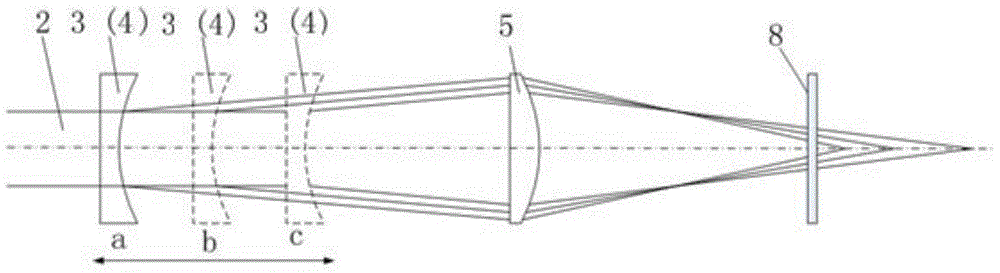

[0040] (2) The computer 10 calculates the appropriate poses of the first and second concave cylindrical lenses 3 and 4 and the x-direction scanning galvanometer 13 and the z-direction scanning galvanometer 14 according to the coordinates, and then controls the motion control card 12 to make the first, The second concave cylindrical lenses 3, 4 and the x-direction scanning galvanometer 13 and the z-direction scanning galvanometer 14 move to corresponding poses;

[0041] (3) The laser control card 11 controls the pulsed laser beam 2 to be emitted from the laser 1, first through the dynamic focusing and orthopedic system 6, the cross-sectional shape and focusing position of the puls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com