Patents

Literature

37results about How to "Realize green processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

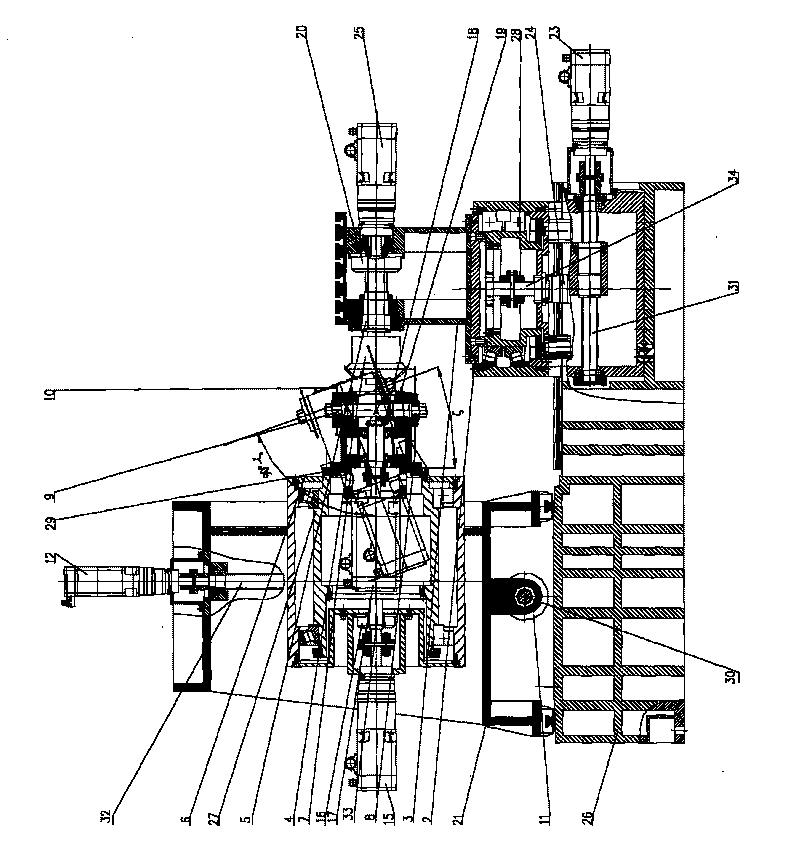

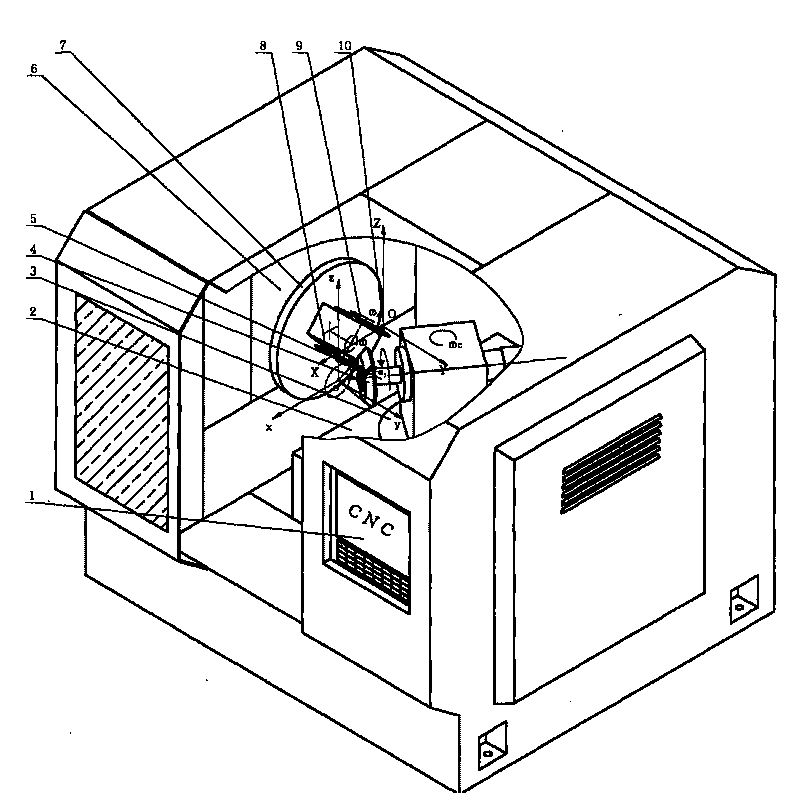

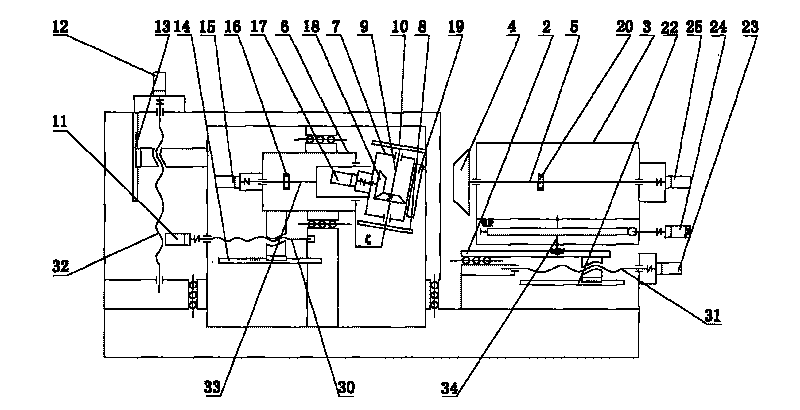

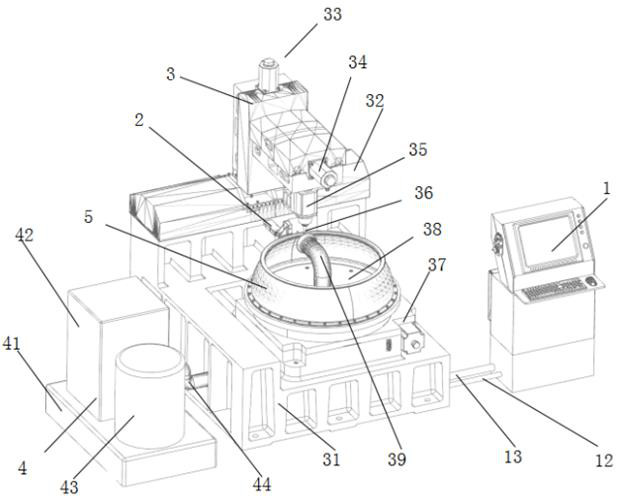

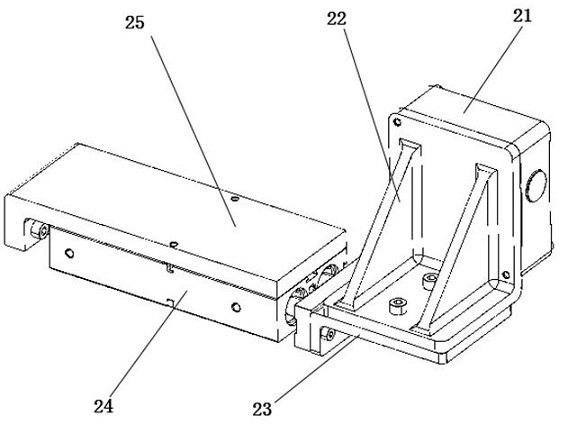

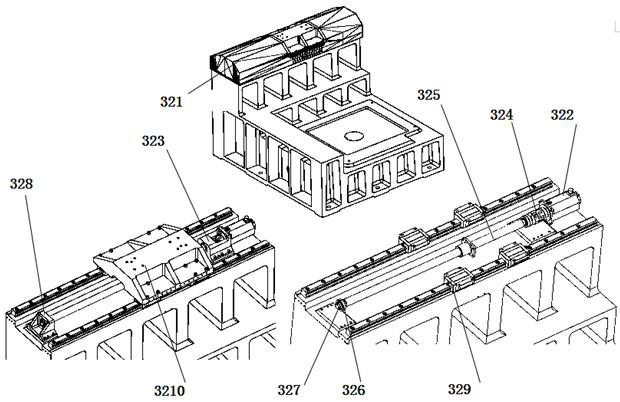

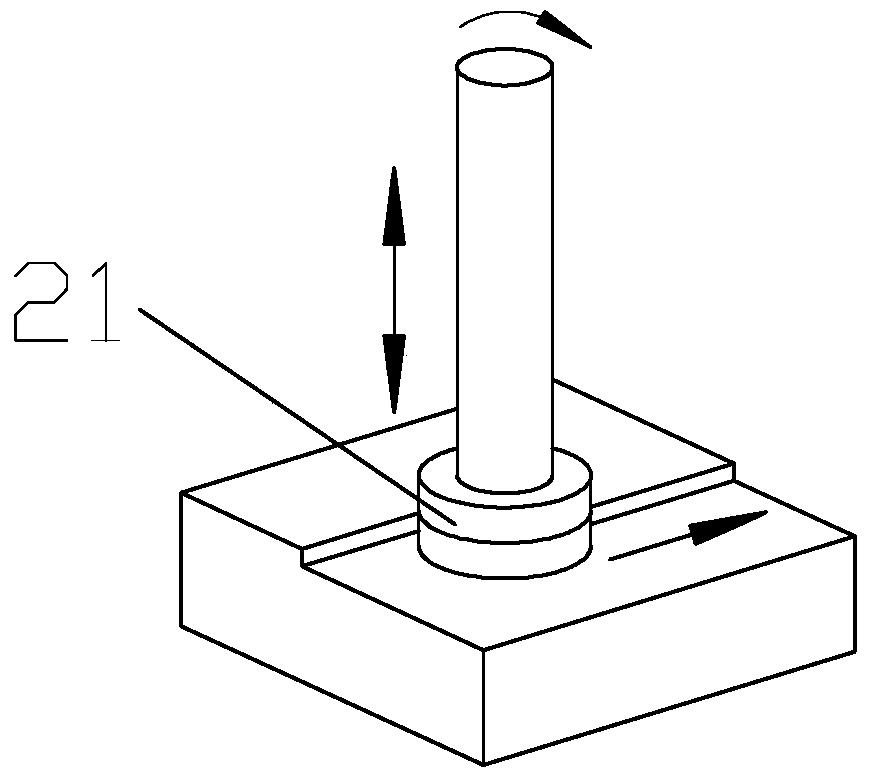

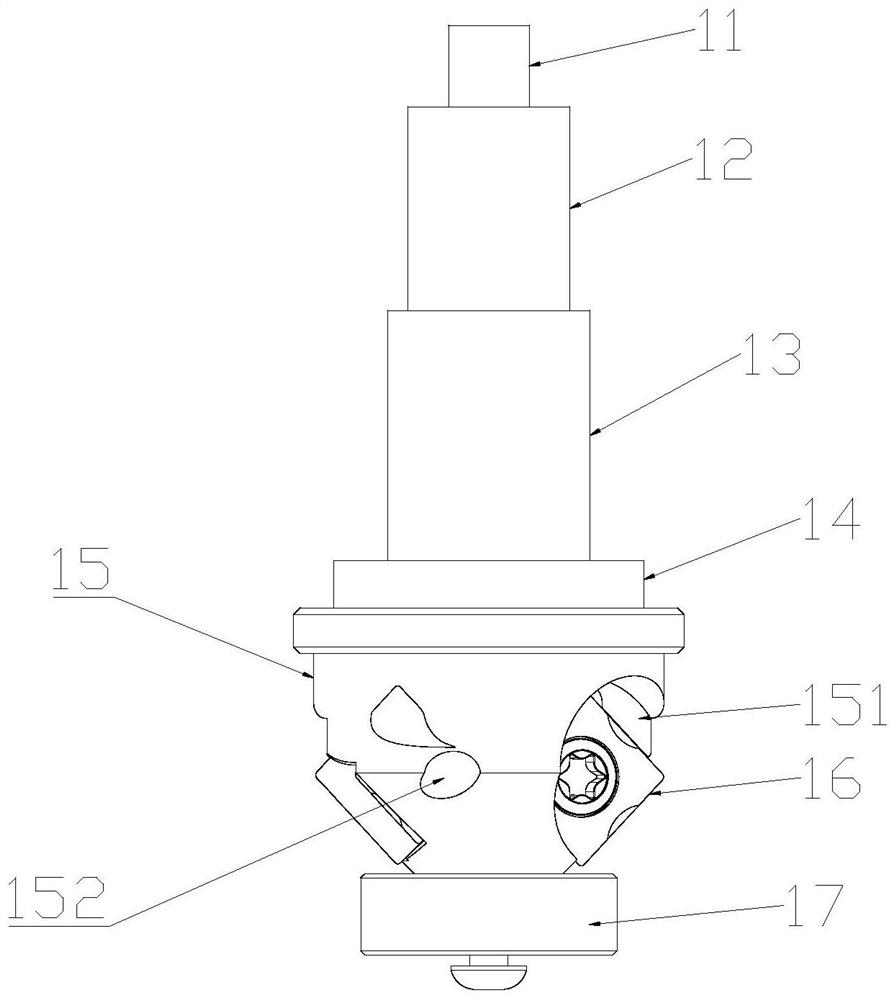

Spiral bevel gear cutting machine tool and gear cutting method

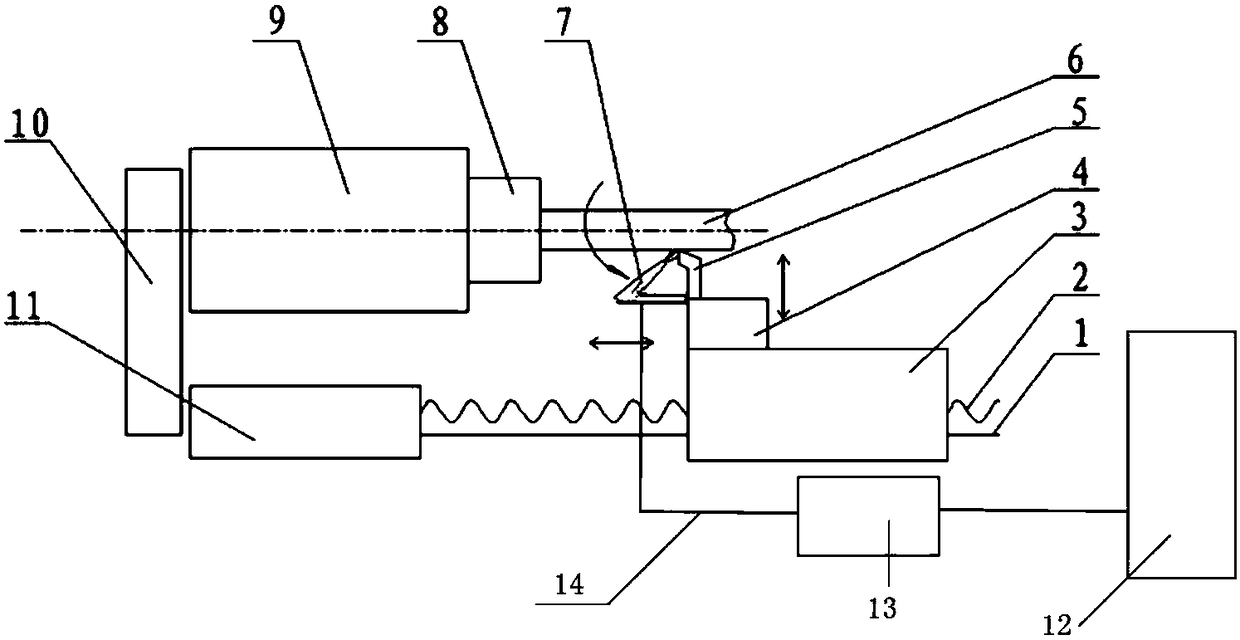

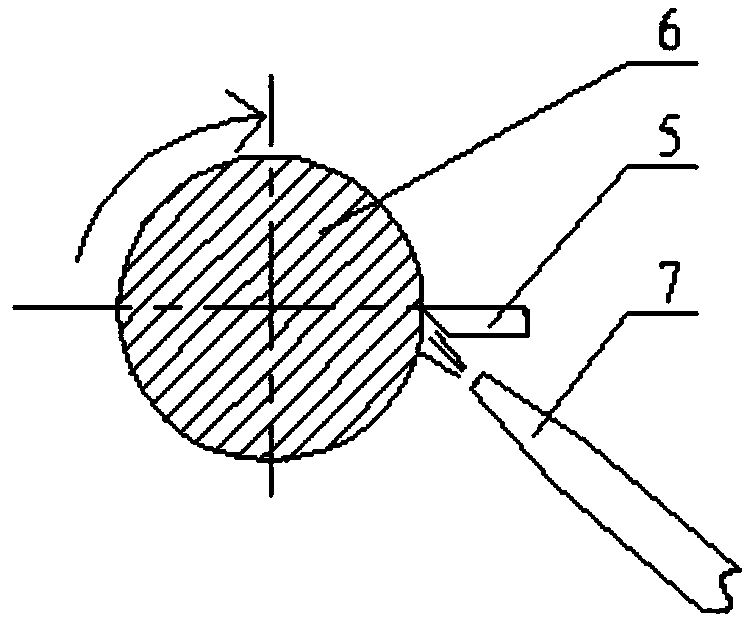

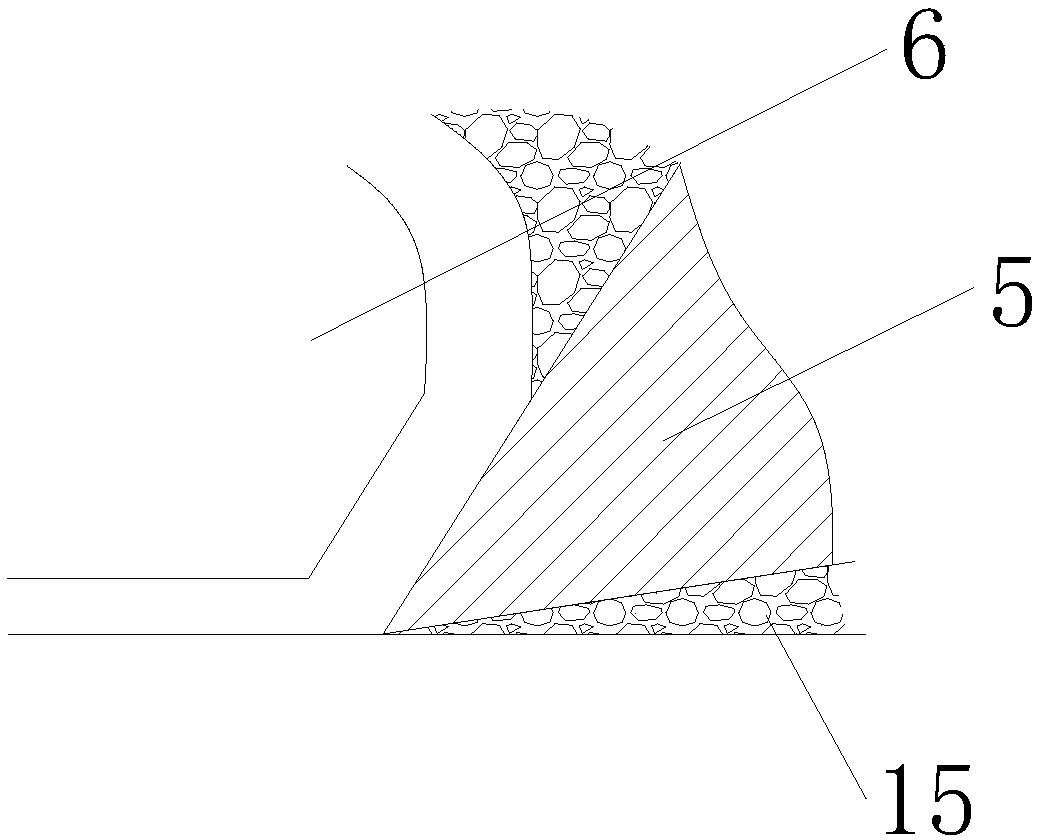

The invention discloses a spiral bevel gear cutting machine tool and a gear cutting method. The gear cutting machine tool comprises a cutting tool system, a workpiece system, a machine tool body and a numerical control system, wherein the cutting tool system comprises an XZ working table, an X-axis lead screw, a Z-axis lead screw, a short shaft, a tool base revolving drum, a tool base, No.1 milling cutters, a milling cutter shaft, No.2 milling cutters, a gear shaft and a correcting wedge. The rotating centre line of the tool base revolving drum and the rotating centre line of the short shaft are collinear; the right end surface of the tool base revolving drum is fixedly connected with an annular flange plate at the left end of the tool base by the correcting wedge; the right end of the tool base is provided with the milling cutter shaft; the rotating centre line of the milling cutter shaft and the rotating centre line of the short shaft are intersectant; and both ends of the milling cutter shaft are provided with the No.1 milling cutters, the No.2 milling cutters or grinding wheels. The left end surface of the tool base is provided with a drive motor; the drive motor is meshed with a bevel gear on the milling cutter shaft by the gear shaft; and the rotating centre line of the output shaft of the drive motor and the rotating centre line of the milling cutter shaft are vertically intersectant. The invention also provides a method for processing helical bevel gears by utilizing the machine tool.

Owner:JILIN UNIV

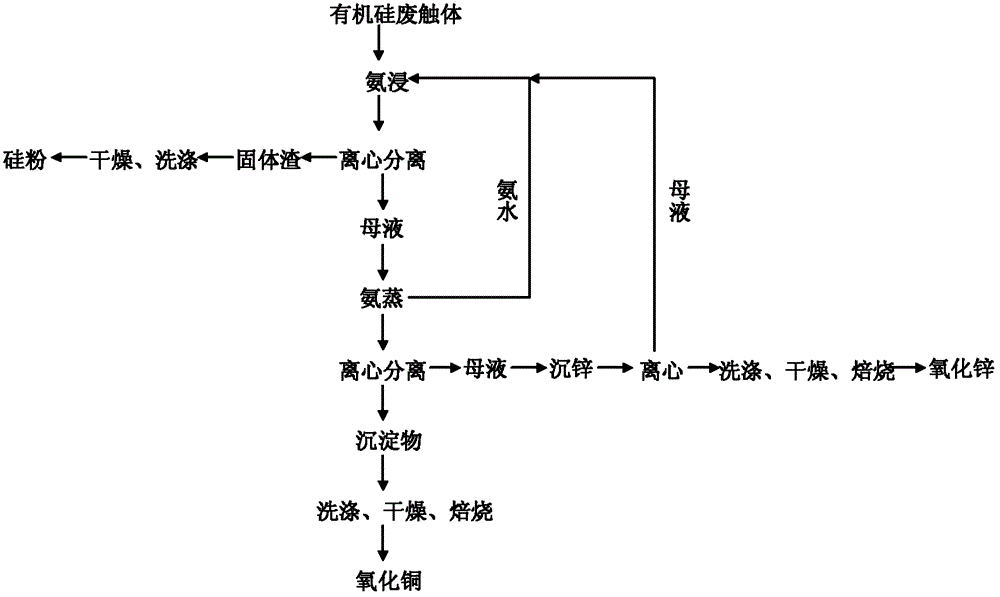

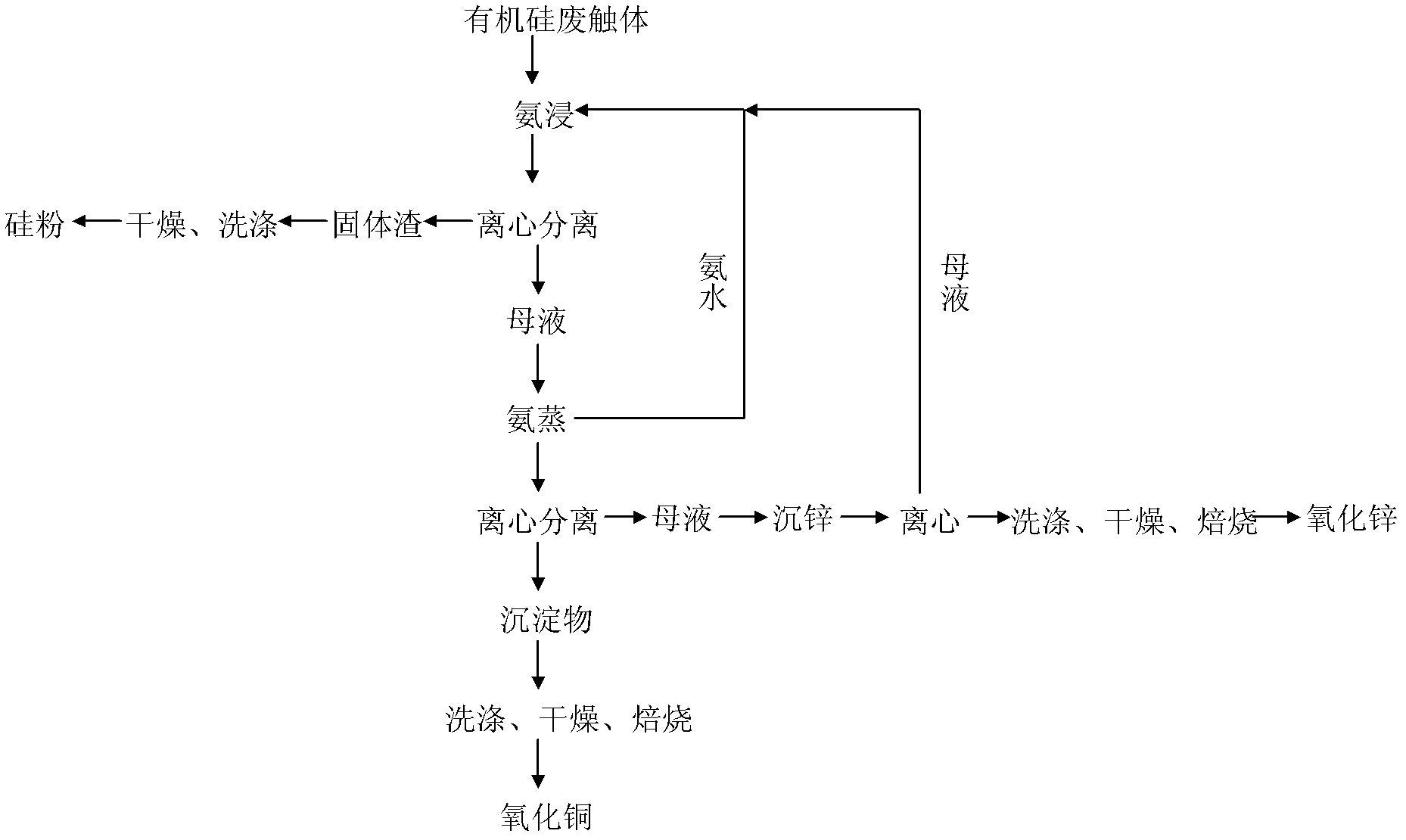

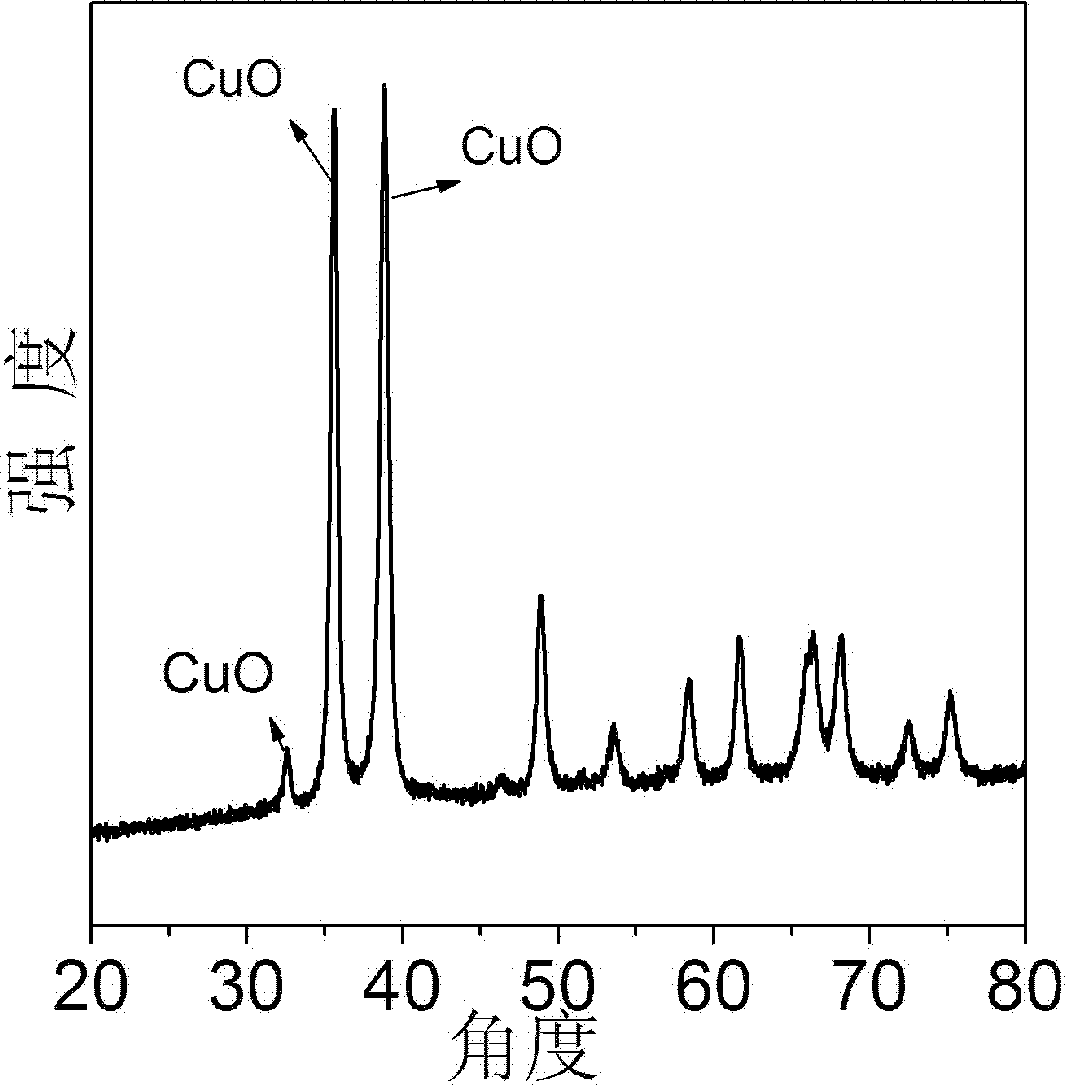

Method for recycling copper oxide and zinc oxide from organosilicon spent contact mass

InactiveCN102795653AShort processImprove efficiencyZinc oxides/hydroxidesCopper oxides/halidesOrganosiliconMother liquor

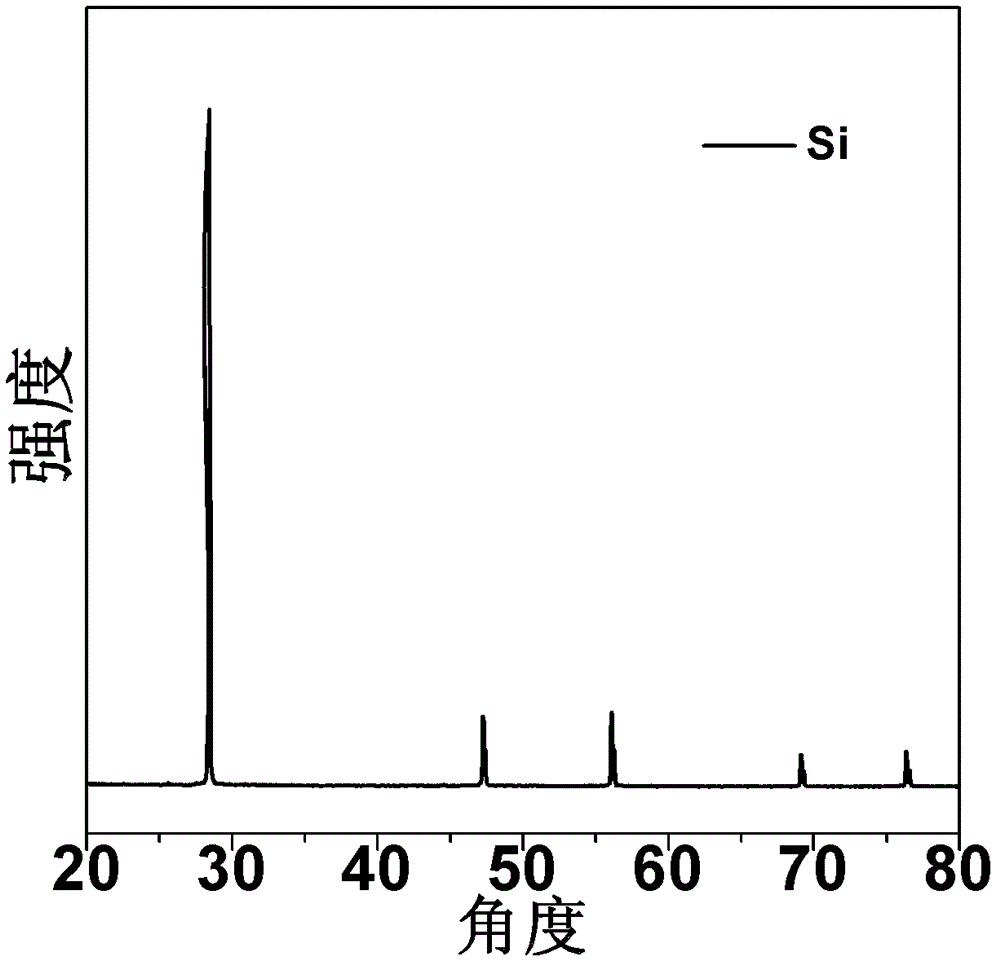

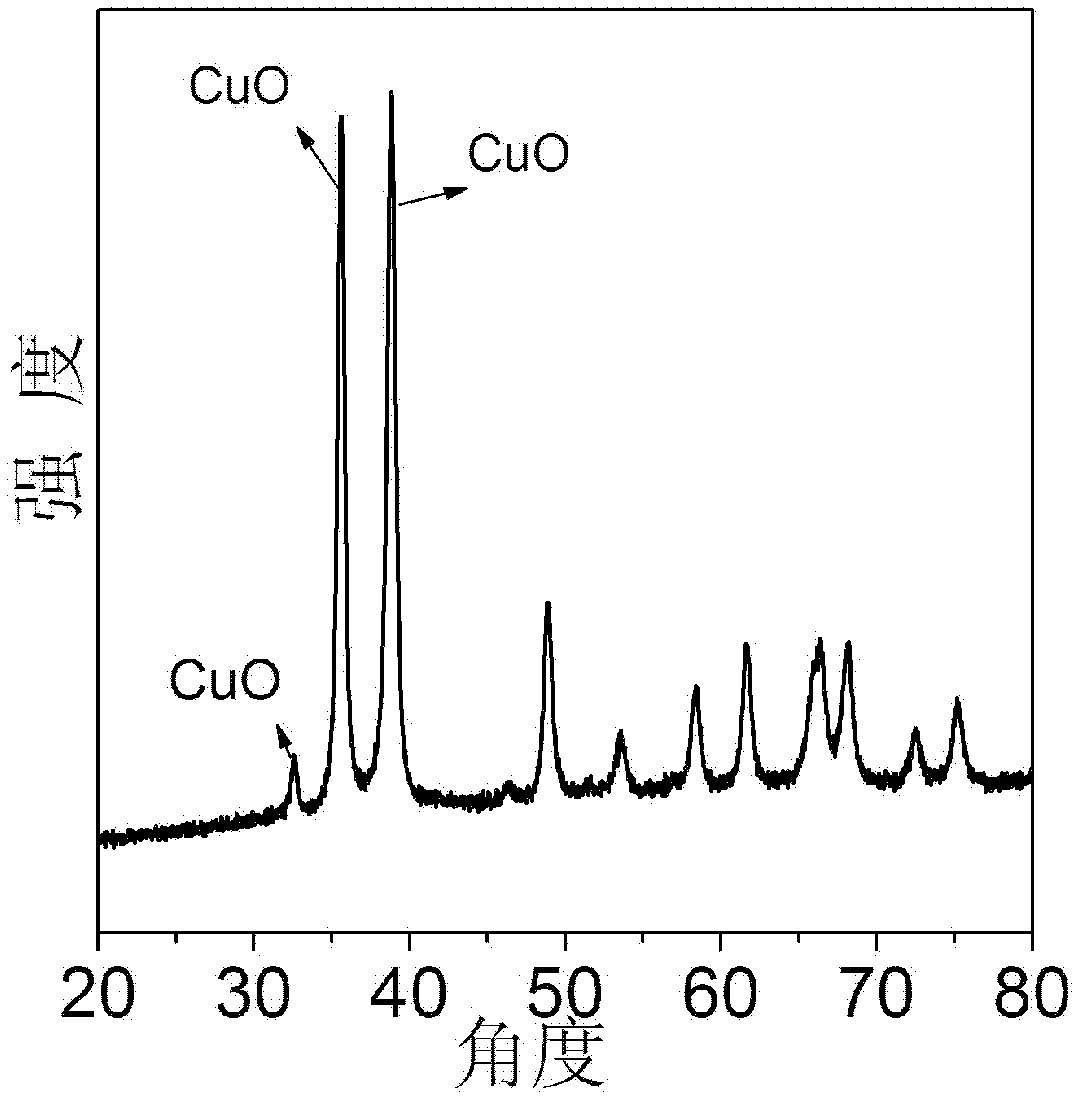

The invention relates to the field of recycling of organosilicon spent contact masses, particularly a method for recycling copper oxide and zinc oxide from an organosilicon spent contact mass, which comprises the following steps: 1) extracting a spent contact mass with an oxidizer-containing ammonia-ammonium salt mixed solution at 20-100 DEG C for 1-8 hours, separating to obtain a copper-ammonia zinc-ammonia complex solution and a solid, and washing and drying the solid to obtain silicon powder; 2) evaporating ammonia from the copper-ammonia zinc-ammonia complex solution at 40-100 DEG C for 1-10 hours to precipitate a copper compound precipitate, separating to obtain the precipitate and a zinc-containing mother solution, washing the precipitate, drying and roasting to obtain copper oxide powder; and 3) adding an ammonium salt into the zinc-containing mother solution obtained in the step 2), regulating the temperature to 20-80 DEG C and the pH value to 4-8 to obtain a basic zinc carbonate precipitate, separating, washing, drying and roasting to obtain zinc oxide powder. The yield and purity of the copper oxide obtained by treating the spent contact mass with an ammonia process are respectively higher than 95%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

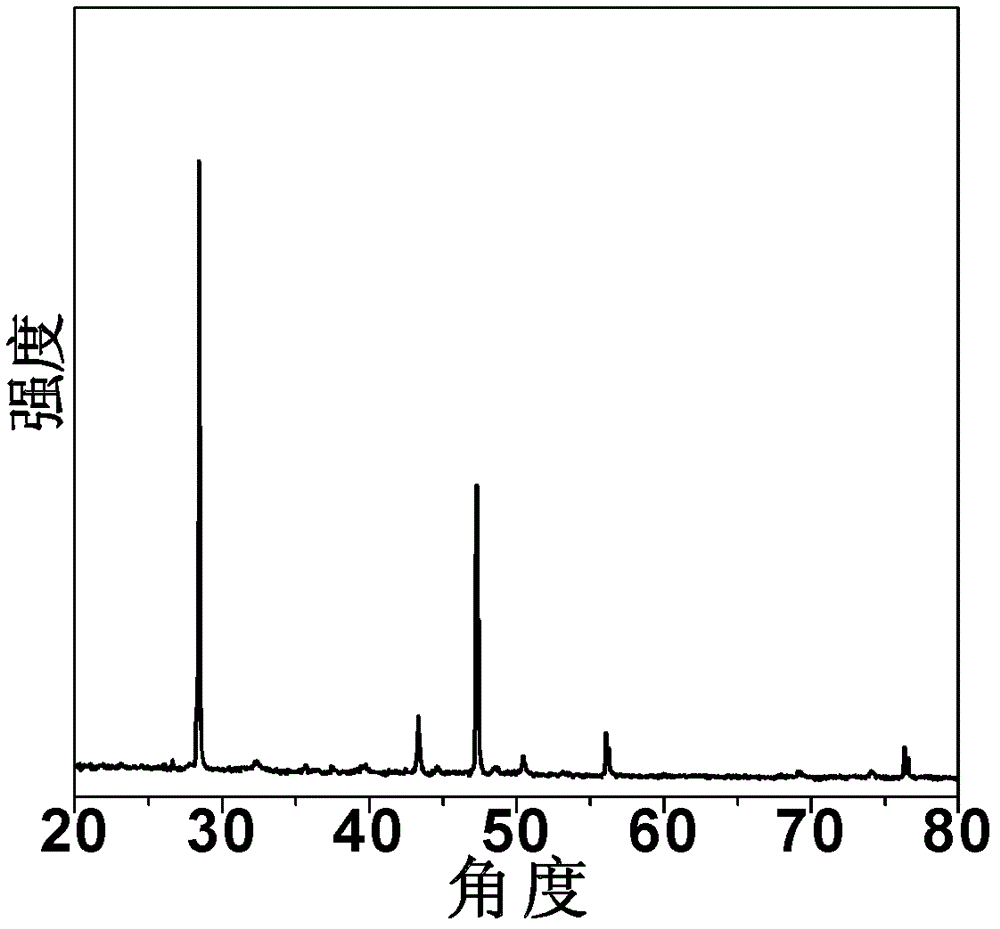

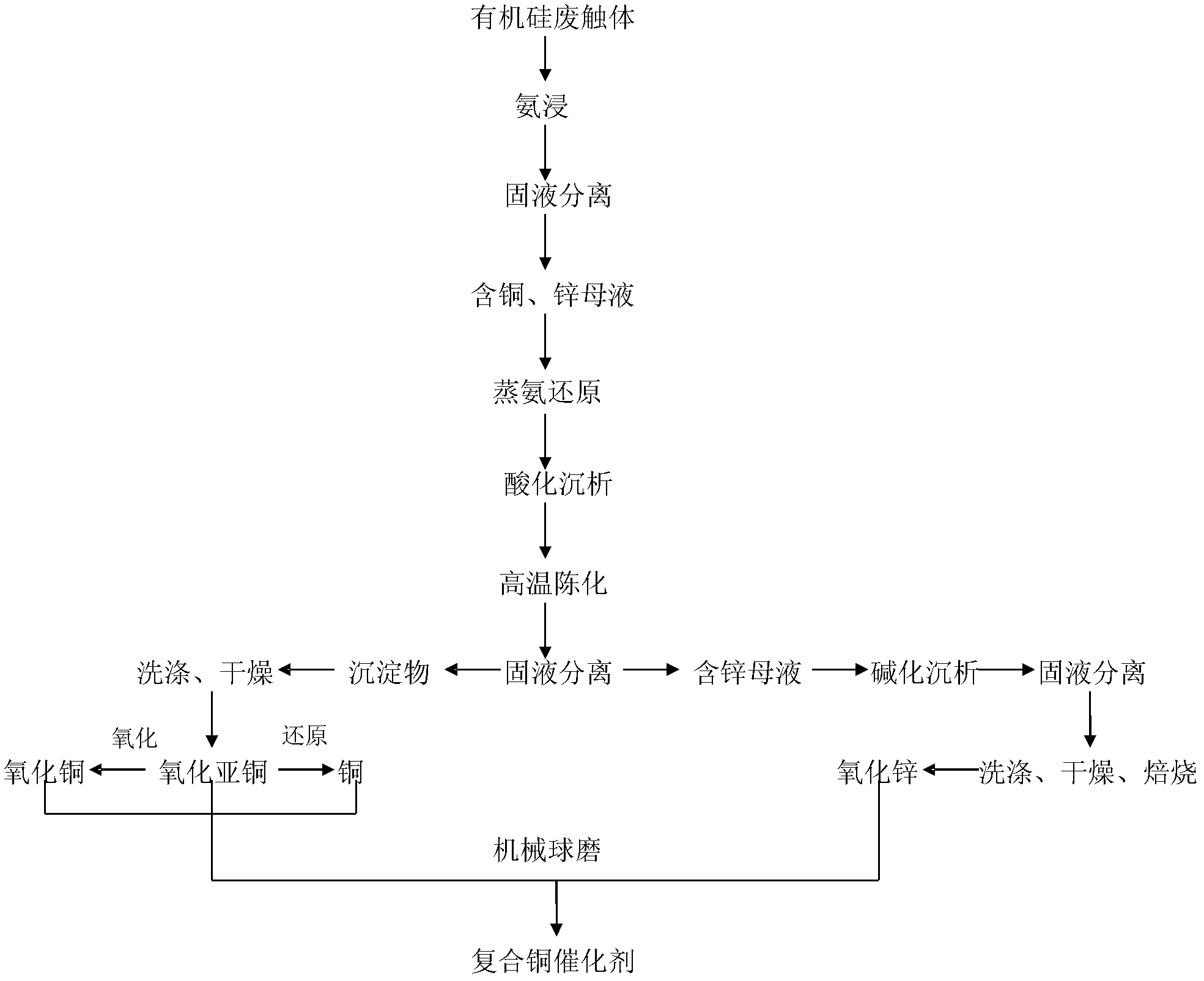

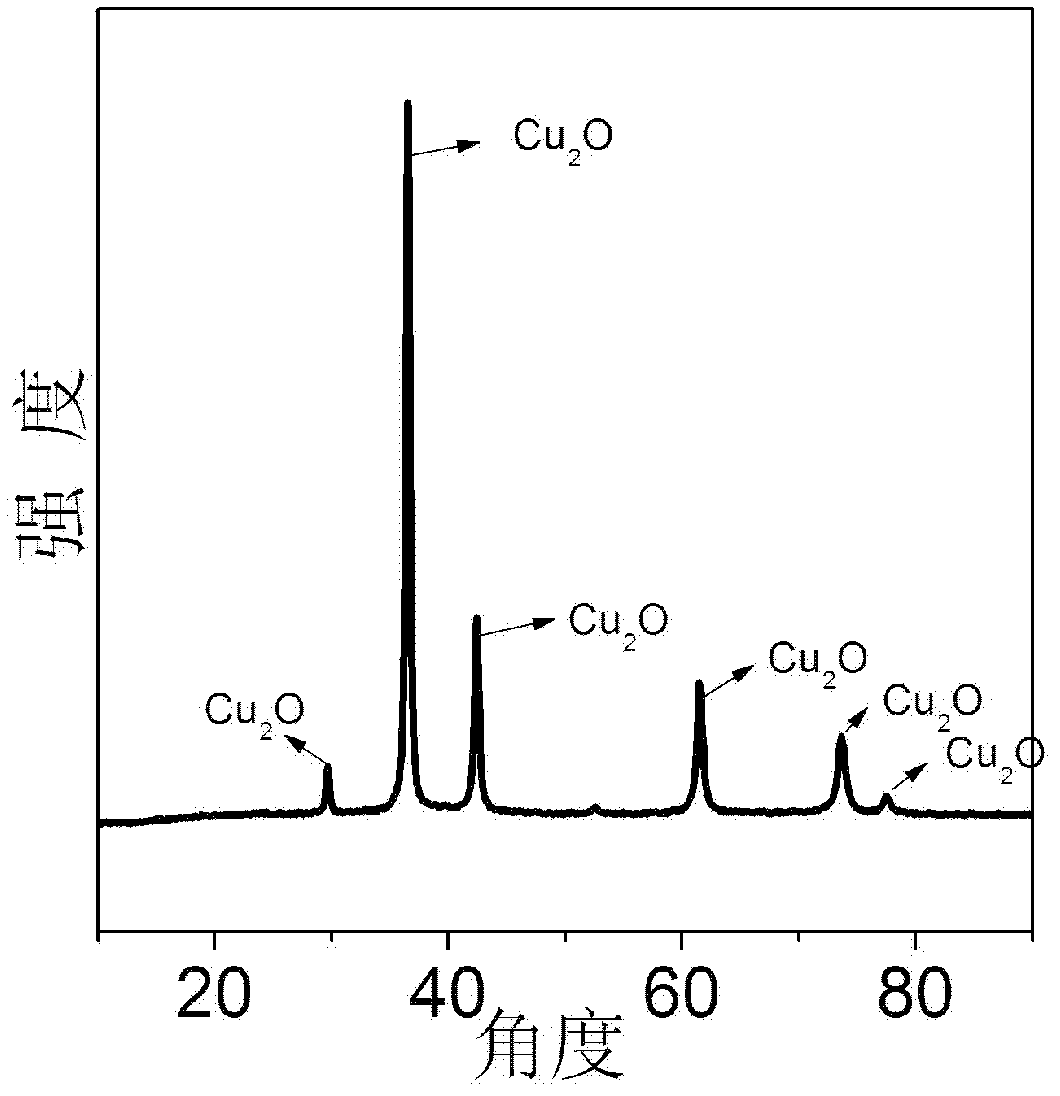

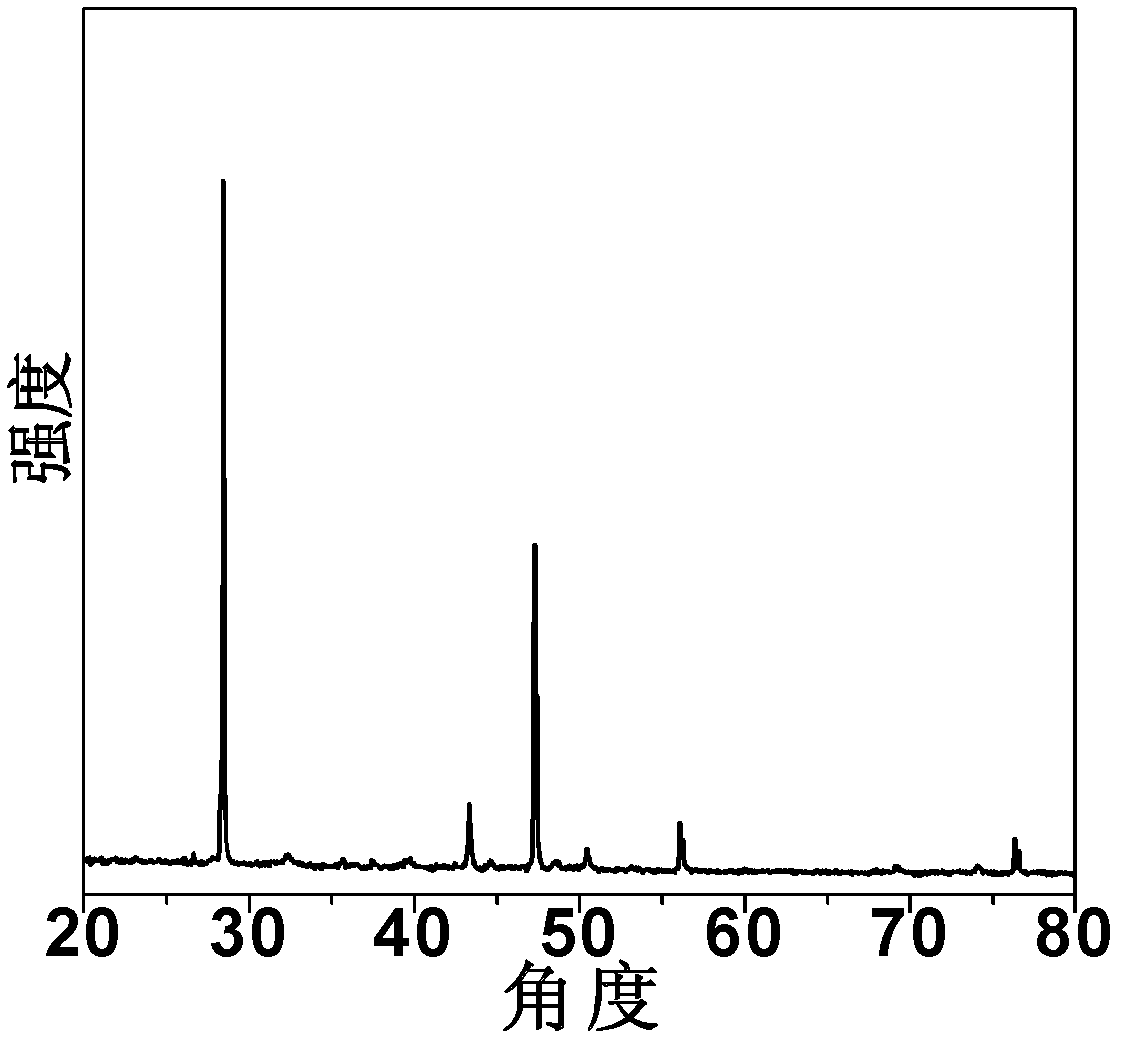

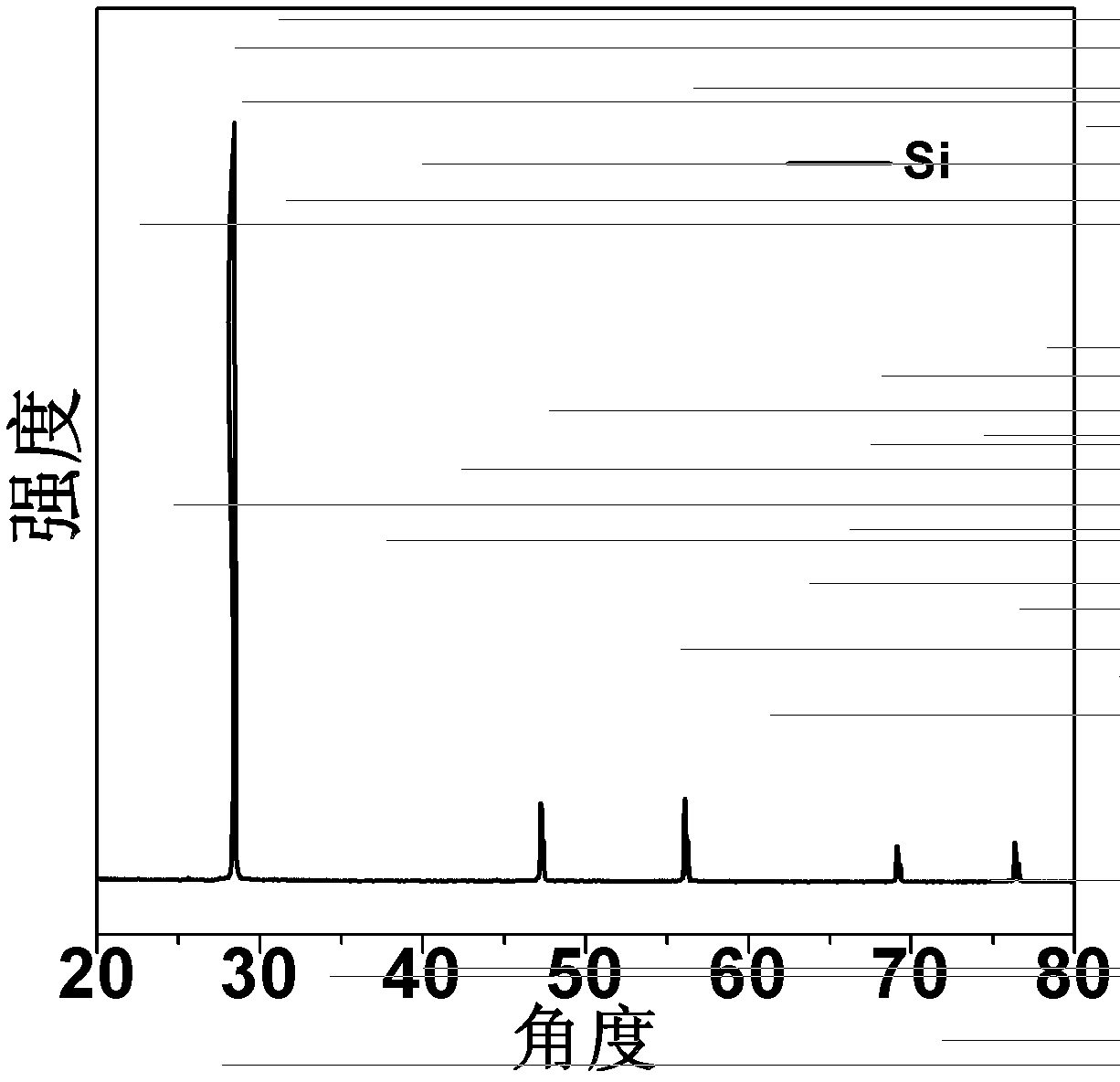

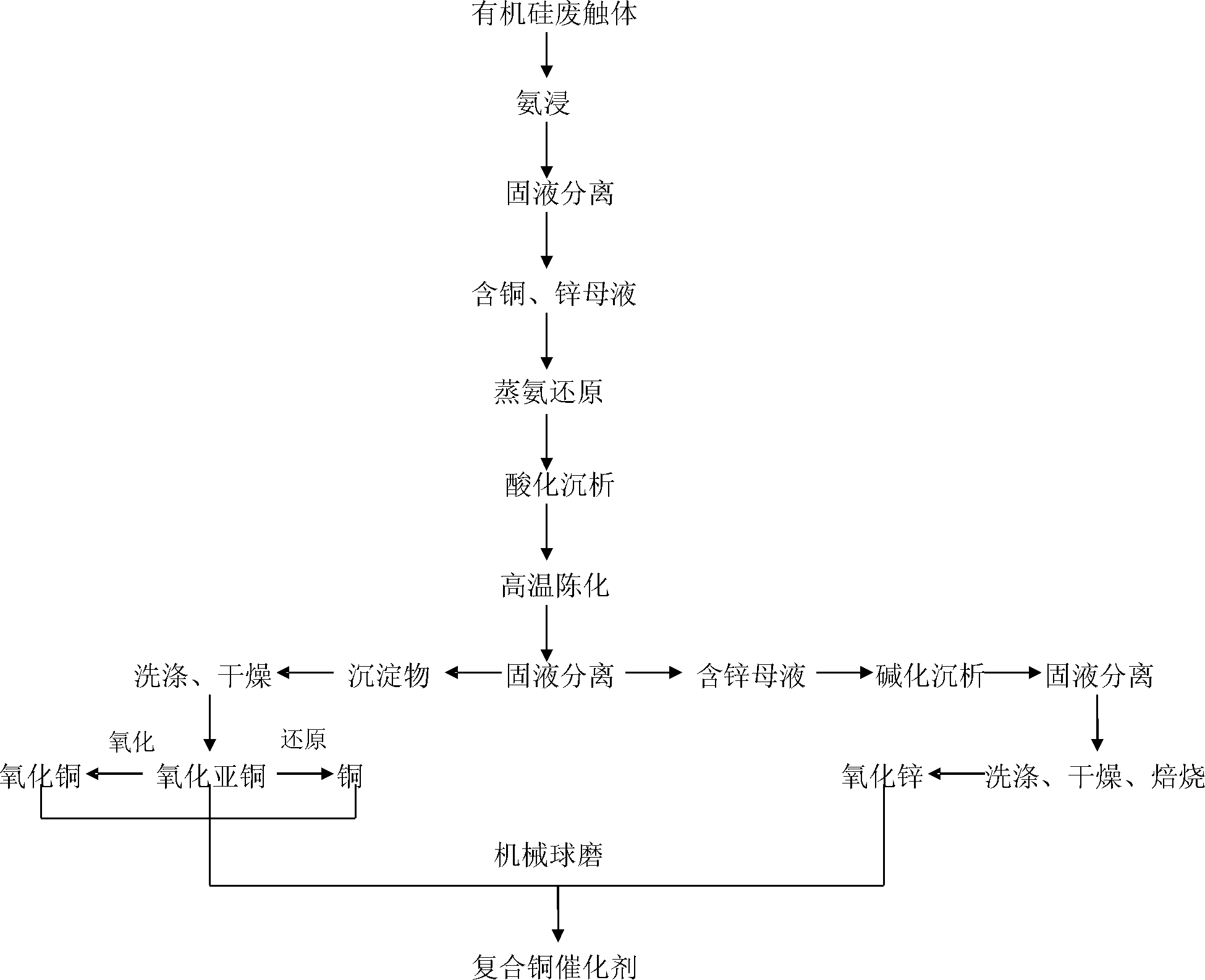

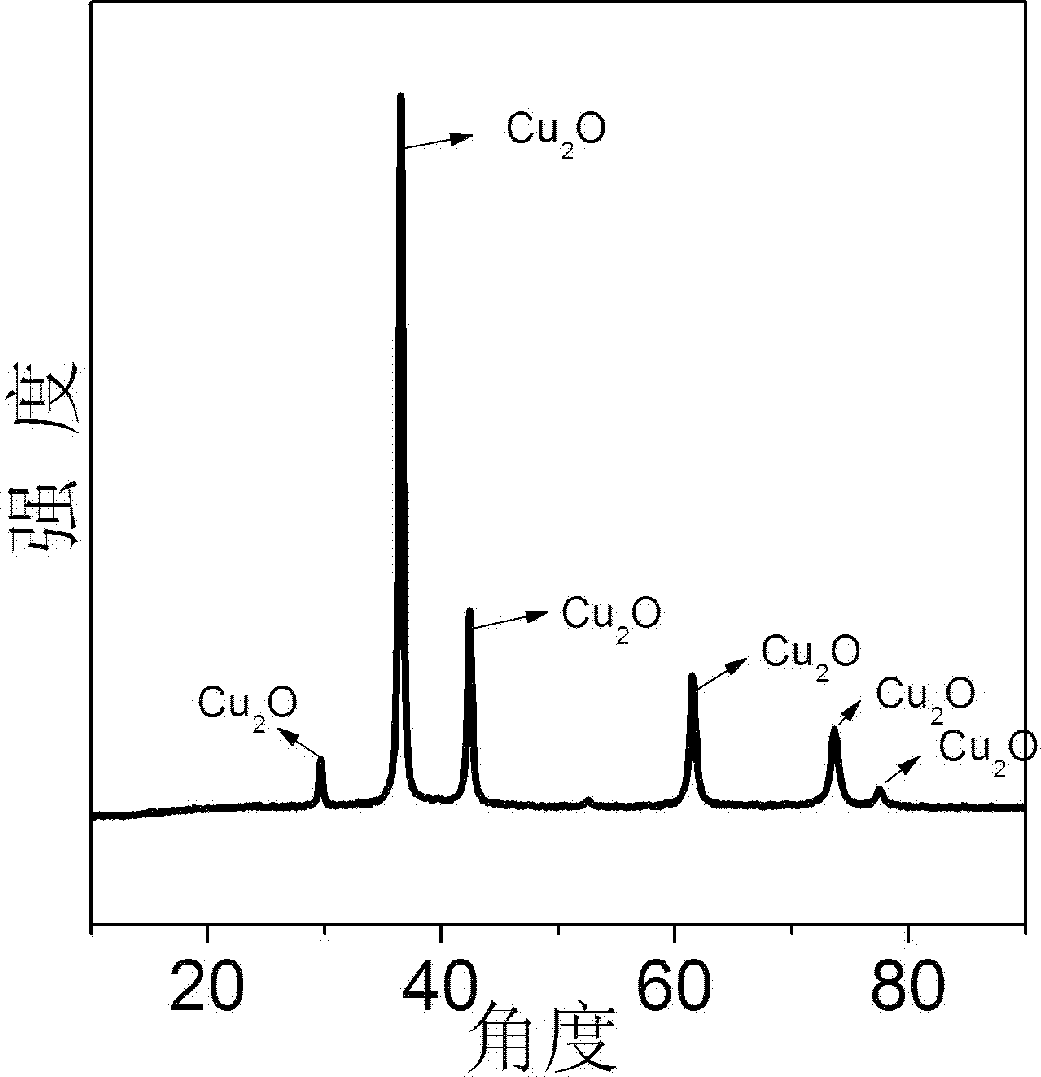

Method for preparing composite copper catalyst by recycling organic silicon waste contacts

InactiveCN102614885ARealize green processingAvoid secondary pollutionGroup 4/14 element organic compoundsChemical recyclingCopper oxideSulfite

The invention relates to a method for preparing a composite copper catalyst by recycling organic silicon waste contacts. The method comprises the following steps of: performing ammonia leaching on the organic silicon waste contacts, adding sulfite into the solution, and performing ammonia distilling reduction; acidizing for precipitating, aging at high temperature to obtain zinc-containing mother liquor and precipitates, and treating the precipitates to obtain cuprous oxide powder; alkalinizing the zinc-containing mother liquor for precipitating, and treating to obtain zinc oxide powder; oxidizing a part of cuprous oxide powder to obtain copper oxide powder, and reducing a part of cuprous oxide powder to obtain copper powder; and mixing the cuprous oxide powder, the zinc oxide powder, the copper oxide powder and the copper powder, and grinding to obtain the composite copper catalyst. According to the composite copper catalyst for synthesizing methyl chlorosilane, products obtained by recycling the waste contacts are used as raw materials, so that the production cost of the copper catalyst is saved greatly, the recycling of the copper catalyst in the industry of organic silicon is realized, and the method has the obvious economic and environment-friendly benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

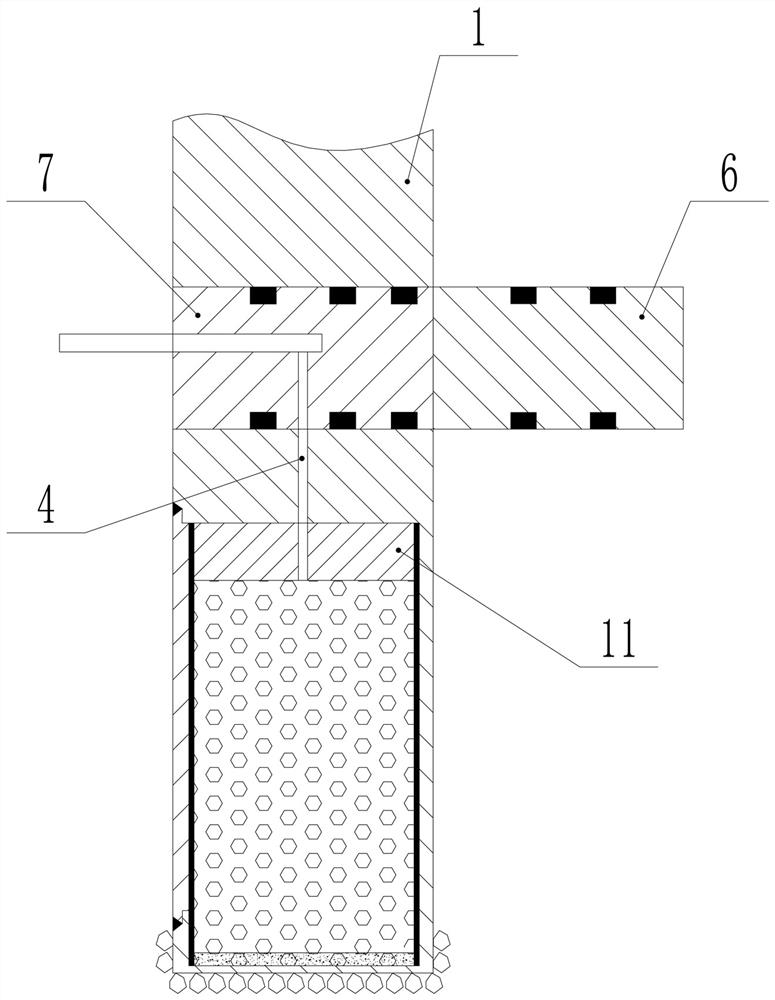

Nitrogen flow jetting type hard cutting machining device and cutting method

InactiveCN108393741APrevent oxidationImprove surface qualityMaintainance and safety accessoriesChemical reactionEngineering

The invention relates to the technical field of hard cutting machining, in particular to a nitrogen flow jetting type hard cutting machining device. According to the device and the method, a superhardcutter is adopted to perform cutting machining on a quenched workpiece, in the machining process, normal-temperature nitrogen separated by a nitrogen making machine from air passes from a nitrogen controller to a high-pressure nitrogen jet head to be jetted to the machining surface of the quenched workpiece at a high speed, on one hand, functions of strong-gas cleaning, lubricating and proper cooling are achieved through the gas medium, on the other hand, the nitrogen is used for isolating and protecting the surface of the workpiece against being oxidized, the machining surface is promoted toundergo friction chemical reaction with the nitrogen, a nitrogen-enriched layer which is beneficial to enhancing the surface quality is generated on the surface of the workpiece, and the method is awater-saving, material-saving and energy-saving green machining novel method without a cutting fluid required, with rough grinding replaced by lathe turning for machining the quenched workpiece.

Owner:GUANGZHOU UNIVERSITY

Technology for strengthening high surface hardness of TC4 titanium alloy by electrical spark

The invention discloses a method for improving surface hardness of a TC4 titanium alloy and relates to a method for strengthening the surface of the TC4 titanium alloy by electrical spark, belonging to the technical field of nontraditional machining. Different solid powder materials are added in a near-dry working medium to implement the technology for strengthening the high surface hardness of the TC4 titanium alloy. The method for improving the surface hardness of the TC4 titanium alloy is implemented by the following steps: the TC4 titanium alloy is strengthened by a powder-mixture near-dry electrical spark surface-strengthening method; and the solid powder materials mixed in the working medium respectively are C powder, B4C powder, and a mixture of the C powder and the B4C powder. Experiment parameters in the process of strengthening the surface by powder-mixture near-dry electrical spark are that the pulse interval toff is equal to 150Mus, the pulse width ton is equal to 150Mus, the pulse current ie is equal to 14A, the interelectrode discharge voltage is 120V, the machining depth h is equal to 0.1mm and a tool electrode used is graphite. The technology has the advantages that a strengthened layer and a matrix are combined well, the surface mechanical property is improved remarkably, and the like. The TC4 titanium alloy with the surface being strengthened by the method is up to 1382HV in microhardness, which is increased by 300% compared with that of the original alloy.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

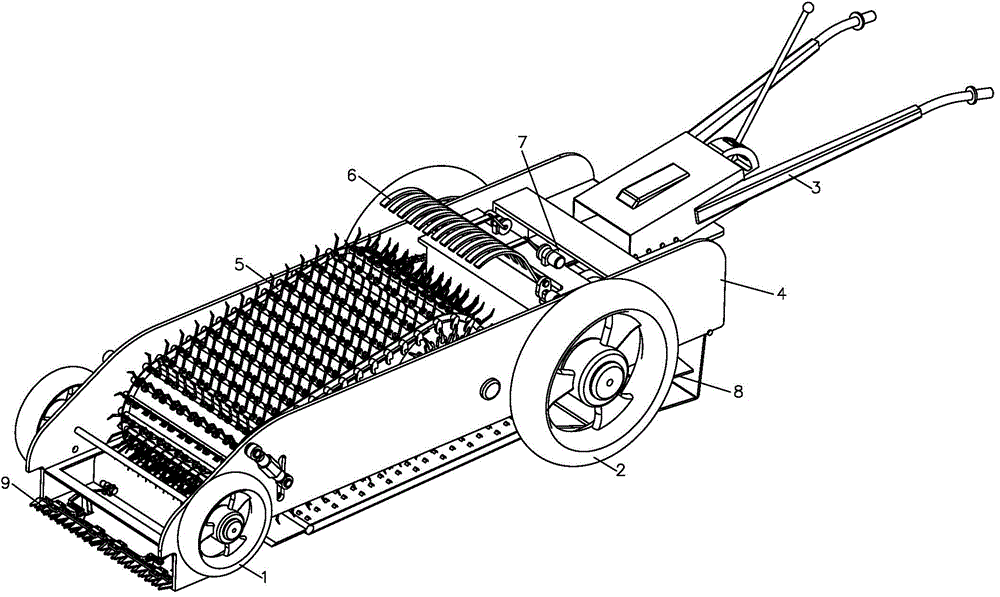

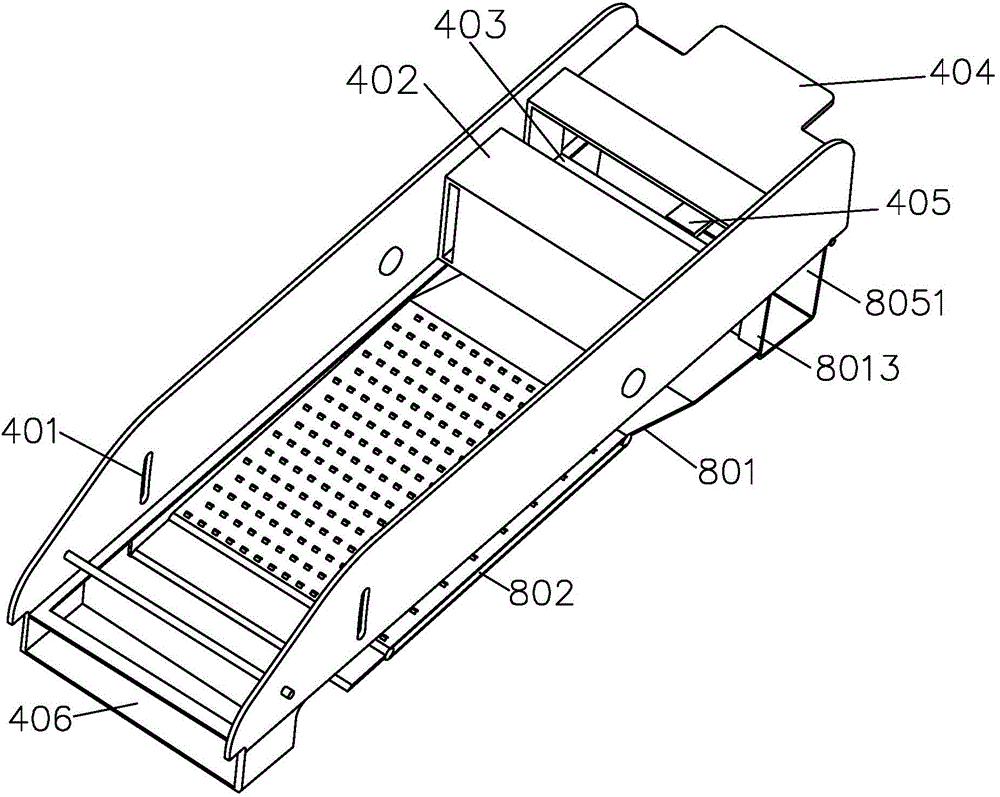

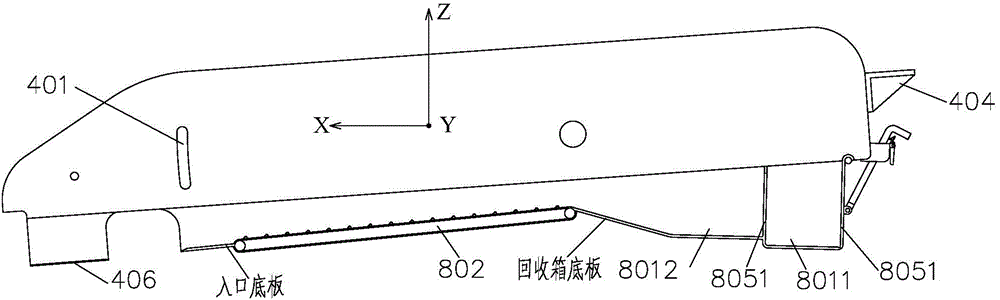

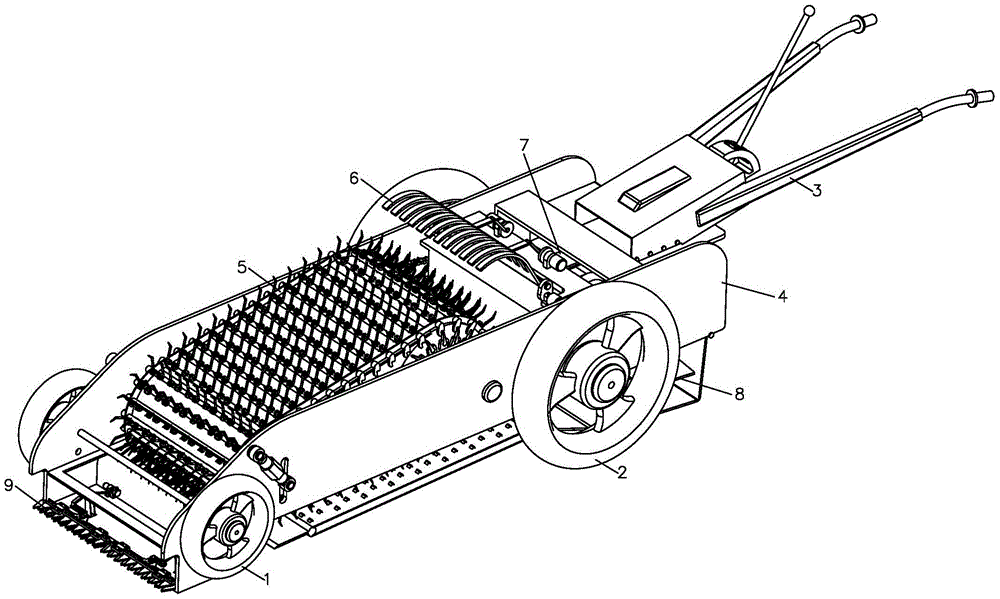

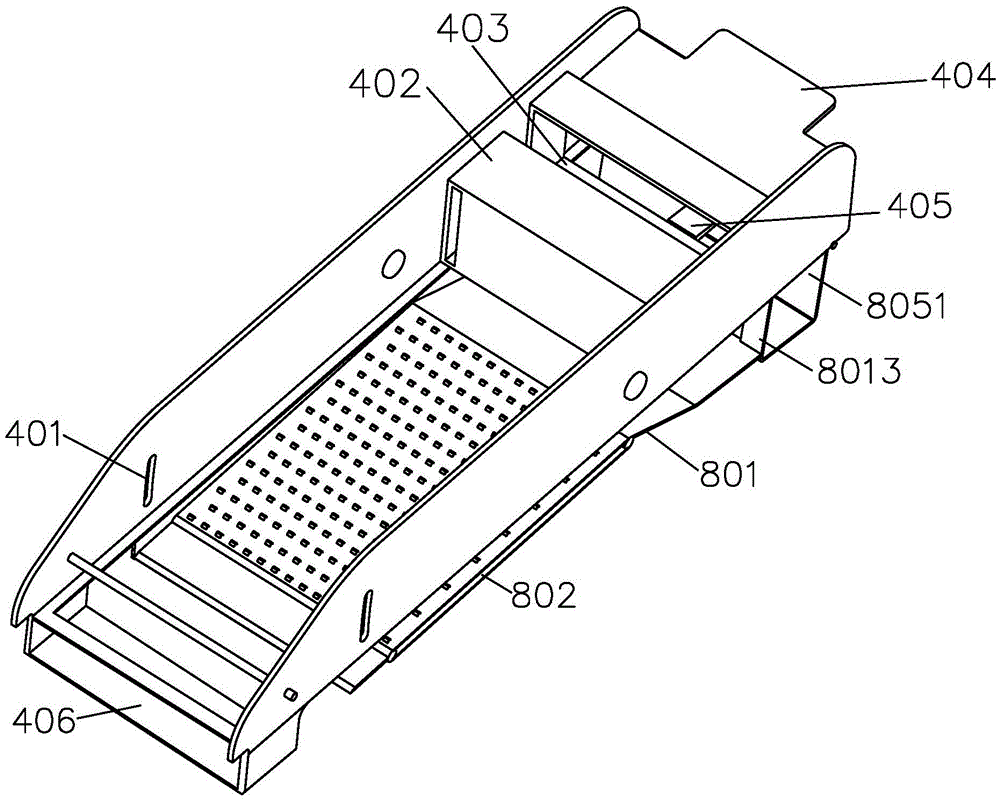

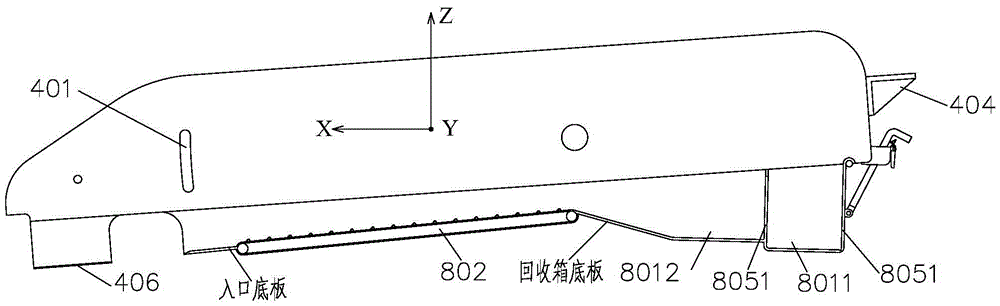

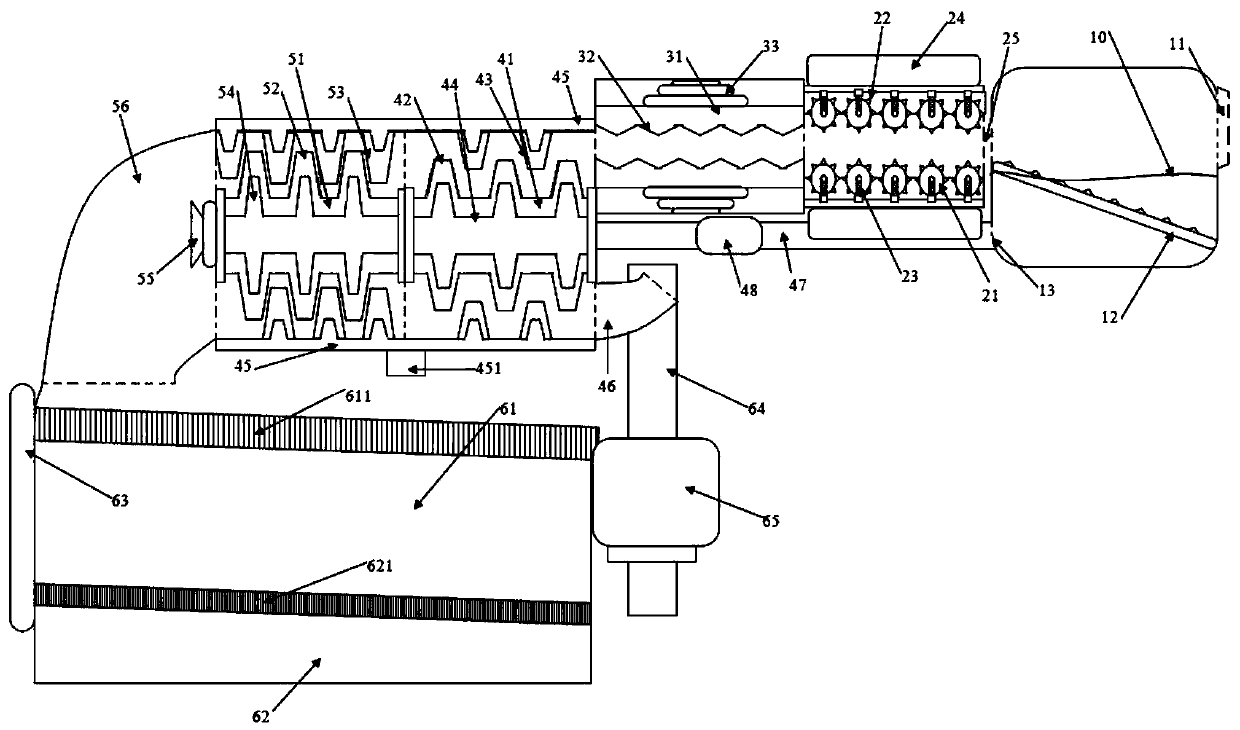

Combine cleaning vehicle for leaves on lawns

InactiveCN104429647AAchieve rotationPrevent reversalHops/wine cultivationTurf growingTorsion springEnvironmentally friendly

The invention discloses a combine cleaning vehicle for leaves on lawns. The combine cleaning device comprises front wheels, rear wheels, handlebars, a frame, a main collecting device, a simulated stripping device, a driving device, a recycling and compressing device and a weeding device. The main collecting device comprises a big roller, a small roller, a main conveying belt, elastic rake teeth, front rake corner adjusting devices, rear rake corner adjusting devices and accelerating devices. The front rake corner adjusting devices comprise suspending rods, adjusting screw tubes and supporting rods. The rear rake corner adjusting devices comprise pawl turnplates, ratchet shifting shanks, rotating shafts, torsion springs, pawls and pawl fixing blocks. The simulated stripping device comprises a large cam, a stripping comb, first connecting rods, second connecting rods and rotating discs. According to the arrangement, the elastic rake teeth are high in adaptability to the lawns with different conditions; the simulated stripping device adopts a design simulating hand stripping movements; by the use of the recycling and compressing device, garbage including leaves is processed environmentally friendly, and wide-range application is available to the schools, the parks and the like.

Owner:ANHUI UNIV OF SCI & TECH

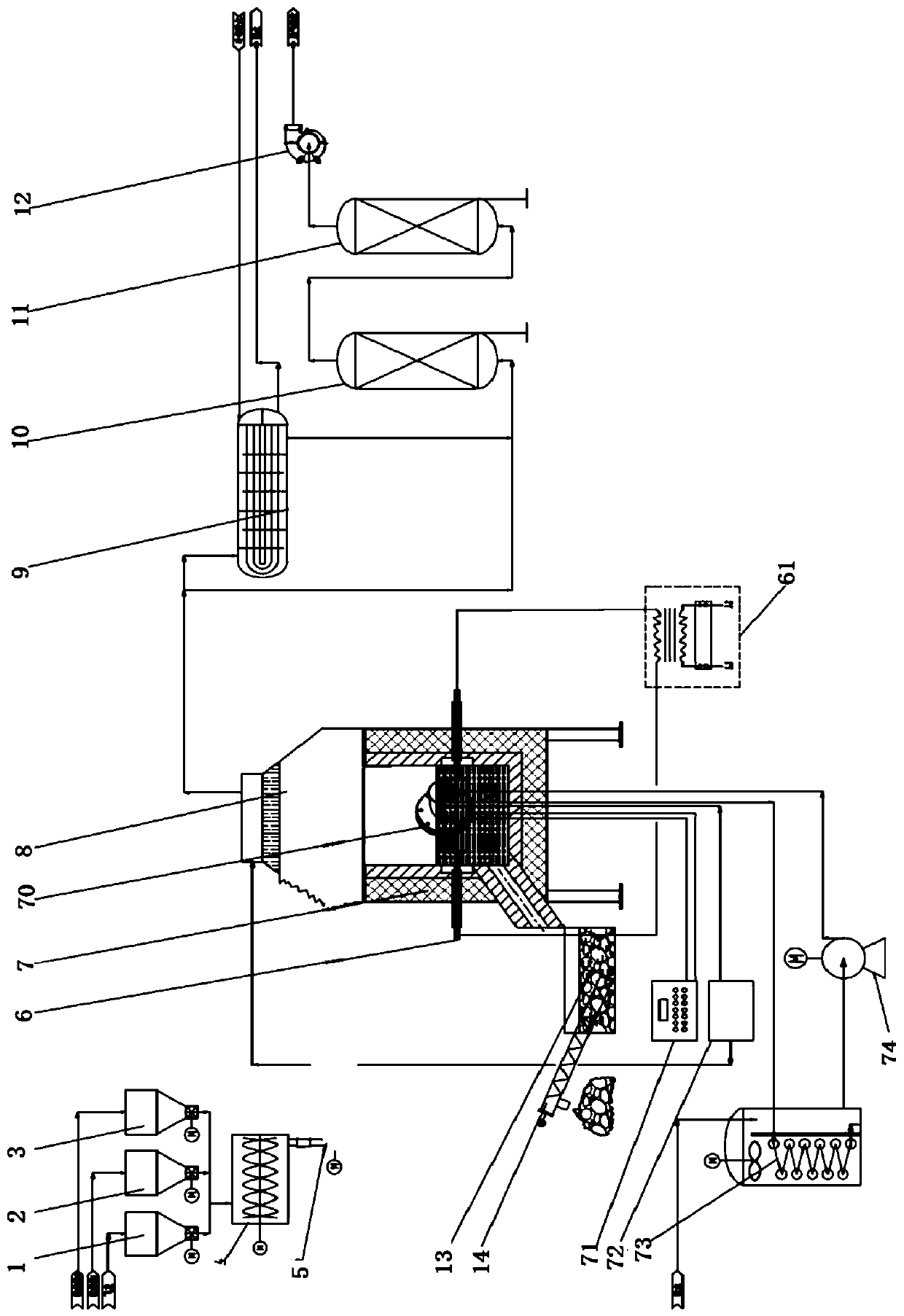

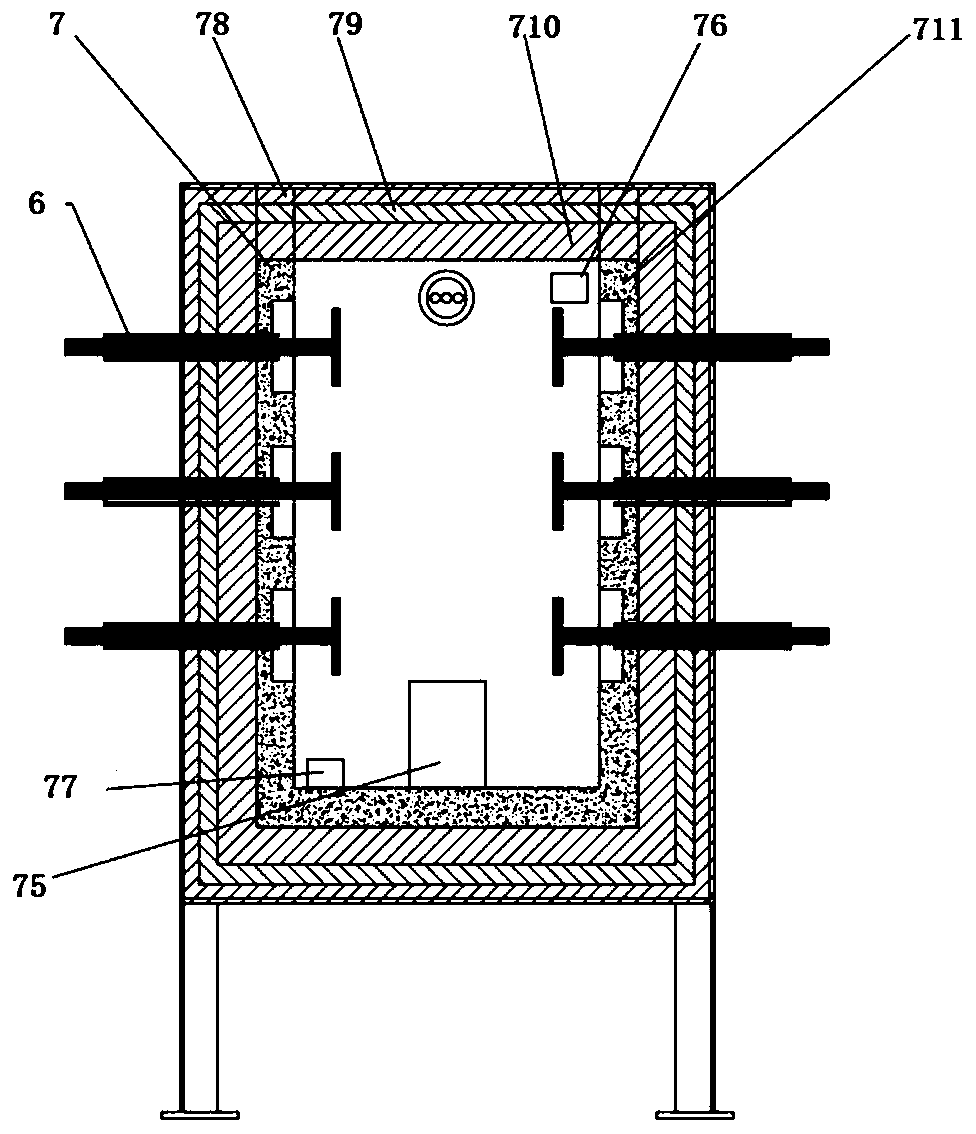

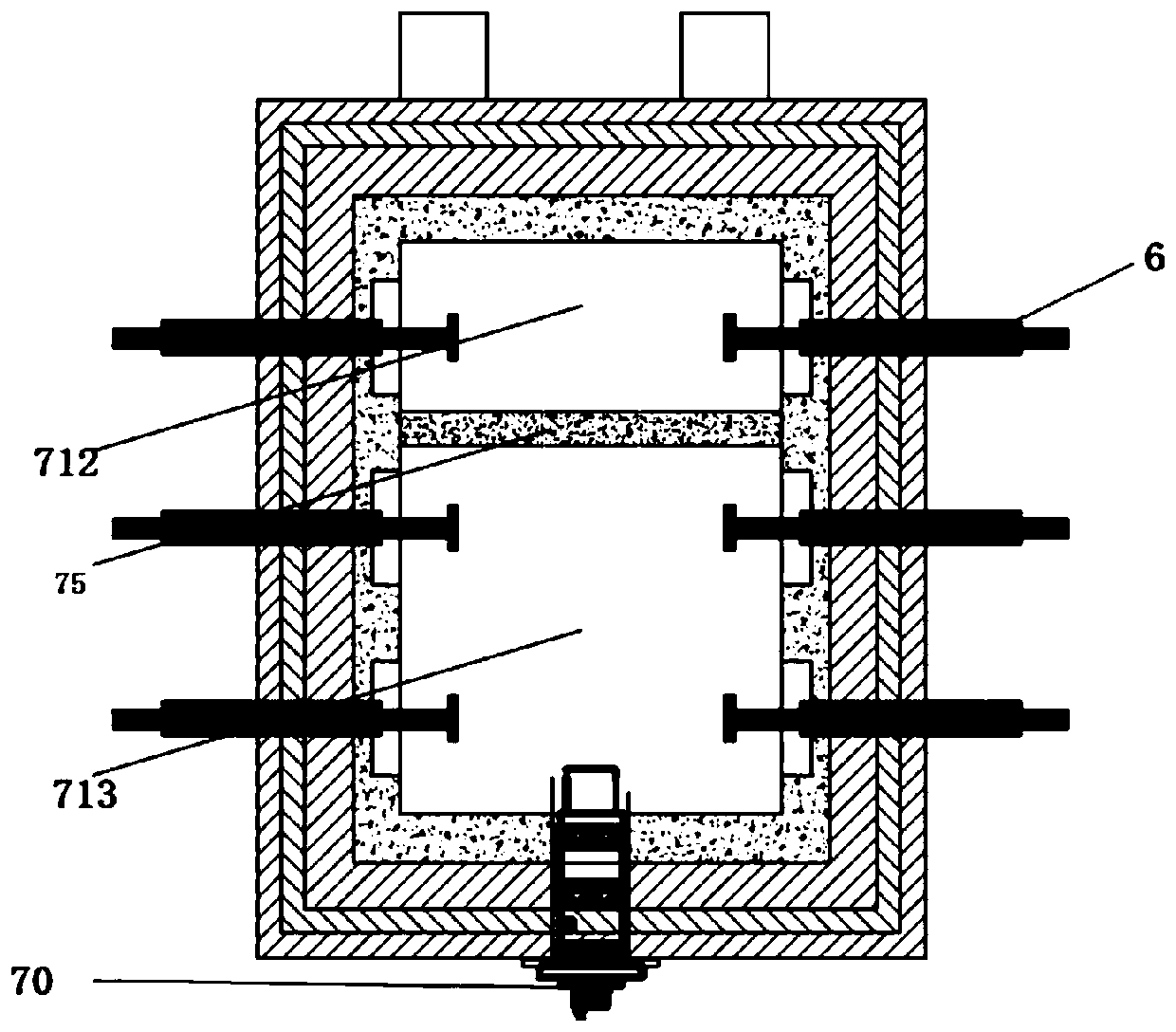

Plasma synergistic resistance furnace fly ash treatment system and treatment method

PendingCN110860553AReduce oxidationExtended service lifeGas treatmentTransportation and packagingSilicon oxygenAtmospheric pollution

The invention provides a plasma synergistic resistance furnace fly ash treatment system and a treatment method. Broken glass (or silicon dioxide powder) is melted by a plasma torch to form a mother solution, the power supply of the plasma torch is cut off, then an electrode power supply is started to be heated by utilizing an electrode, and then the fly ash and the broken glass and the lime are mixed according to a certain proportion (the silicon and calcium ratio is 2-3) and then are uniformly stirred, and then the fly ash and the broken glass and the lime are fed into a melting furnace to besubjected to glass stabilization through a material scattering machine. The organic matters such as dioxin in the fly ash are subjected to high-temperature decomposition, heavy metal cadmium, chromium, lead, copper and other heavy metals enter a grid structure formed by silicon oxygen to be cured and stabilized, and the heavy metal leaching concentration in the glass of the melting furnace is farlower than that of the leaching standard limit value in the GB5085.3-2007, and the fly ash are converted into glass bodies to be subjected to resource utilization after water quenching, the residualorganic matters in the fly ash treated by oxygen-free high-temperature decomposition to generate gas pollutants, and the gas pollutants are subjected to cooling, desulfurization and denitrification treatment, and then discharge is carried out after reaching the atmospheric pollutant emission standard of a GB9078 industrial kiln.

Owner:成都启川新能源科技有限公司

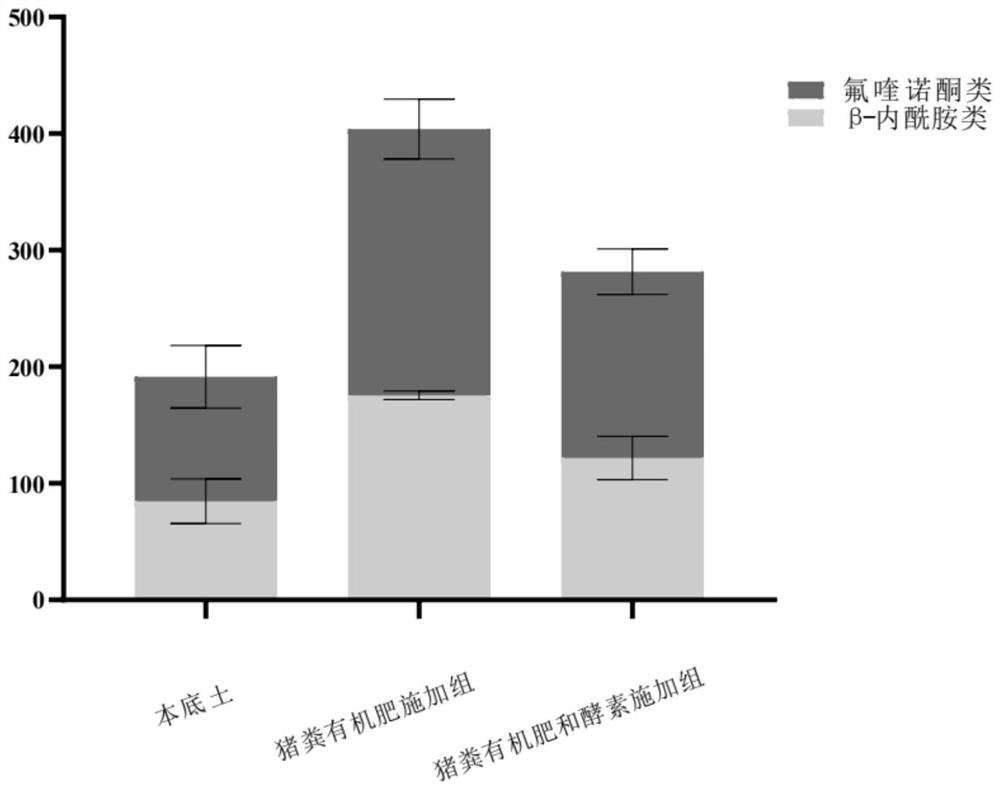

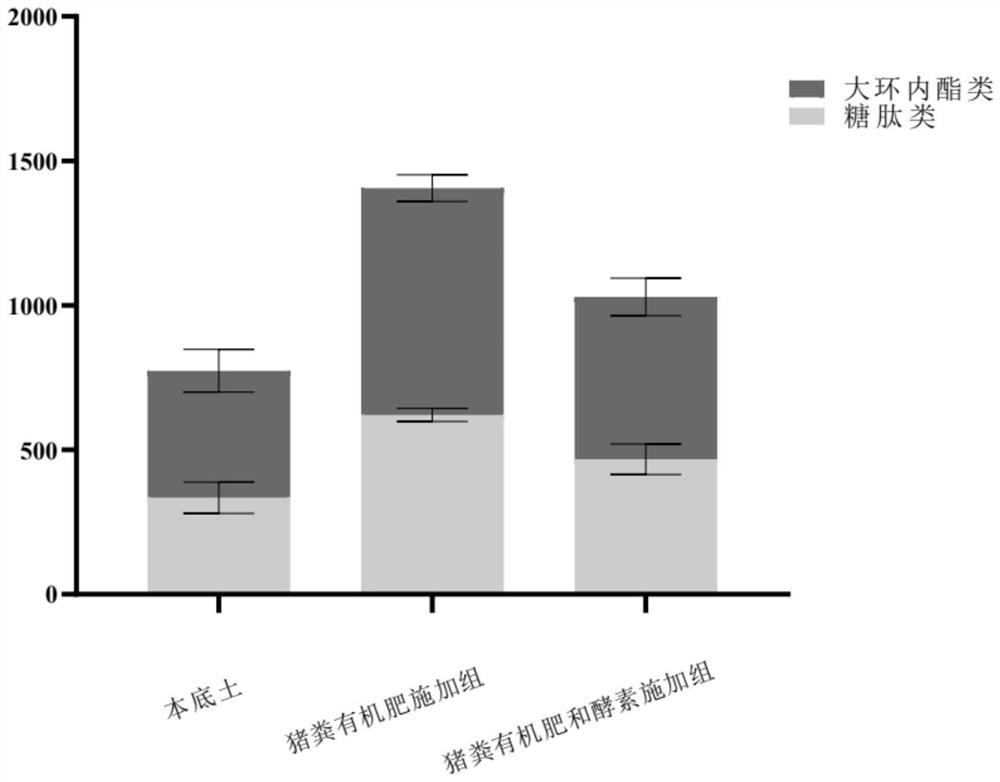

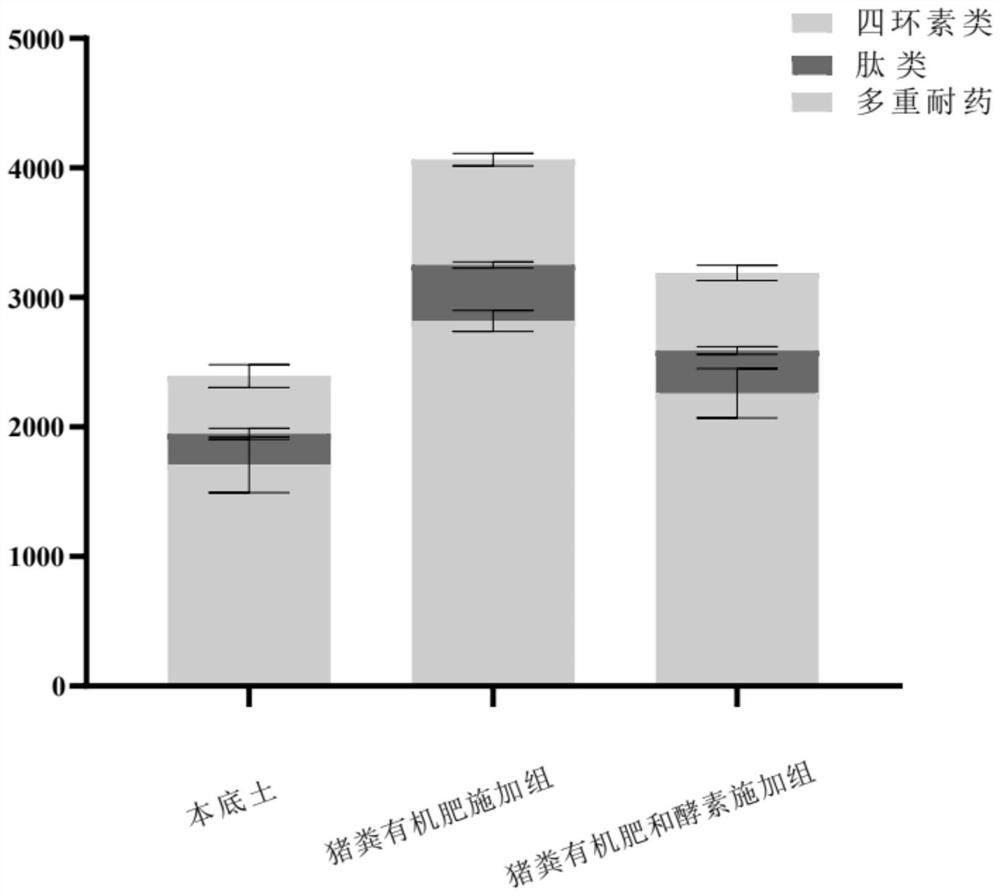

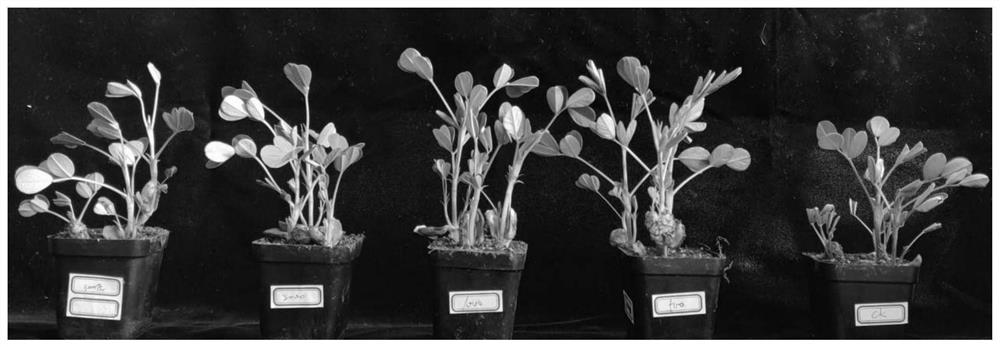

Method for preventing and controlling soil antibiotic resistance gene pollution

PendingCN113943756AReduce proliferationReduce spreadContaminated soil reclamationFermentationBiologyFermentation

The invention discloses a method for preventing and controlling soil antibiotic resistance gene pollution; an agricultural enzyme is used as an impedance agent to be directly applied to polluted soil to be treated or applied to the soil to be treated after fertilizer is applied or applied to the soil to be treated after being evenly mixed with the fertilizer; the agricultural enzyme is a liquid fermentation product obtained by fermenting food wastes; and the polluted soil to be treated is soil polluted by antibiotic resistance genes taking actinomycetes as host bacteria. According to the method, proliferation and diffusion of antibiotic resistance genes in soil are reduced by means of inhibition of the agricultural enzyme on survival of microorganisms such as actinomycetes, namely selection of host microorganisms; and the method is an efficient, broad-spectrum, green, environment-friendly and low-price agricultural environment restoration technology.

Owner:ZHEJIANG GONGSHANG UNIVERSITY +1

Method for recycling copper oxide and zinc oxide from organosilicon spent contact mass

InactiveCN102795653BRealize green processingAvoid secondary pollutionZinc oxides/hydroxidesCopper oxides/halidesCopper oxideZinc

The invention relates to the field of recycling of organosilicon spent contact masses, particularly a method for recycling copper oxide and zinc oxide from an organosilicon spent contact mass, which comprises the following steps: 1) extracting a spent contact mass with an oxidizer-containing ammonia-ammonium salt mixed solution at 20-100 DEG C for 1-8 hours, separating to obtain a copper-ammonia zinc-ammonia complex solution and a solid, and washing and drying the solid to obtain silicon powder; 2) evaporating ammonia from the copper-ammonia zinc-ammonia complex solution at 40-100 DEG C for 1-10 hours to precipitate a copper compound precipitate, separating to obtain the precipitate and a zinc-containing mother solution, washing the precipitate, drying and roasting to obtain copper oxide powder; and 3) adding an ammonium salt into the zinc-containing mother solution obtained in the step 2), regulating the temperature to 20-80 DEG C and the pH value to 4-8 to obtain a basic zinc carbonate precipitate, separating, washing, drying and roasting to obtain zinc oxide powder. The yield and purity of the copper oxide obtained by treating the spent contact mass with an ammonia process are respectively higher than 95%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

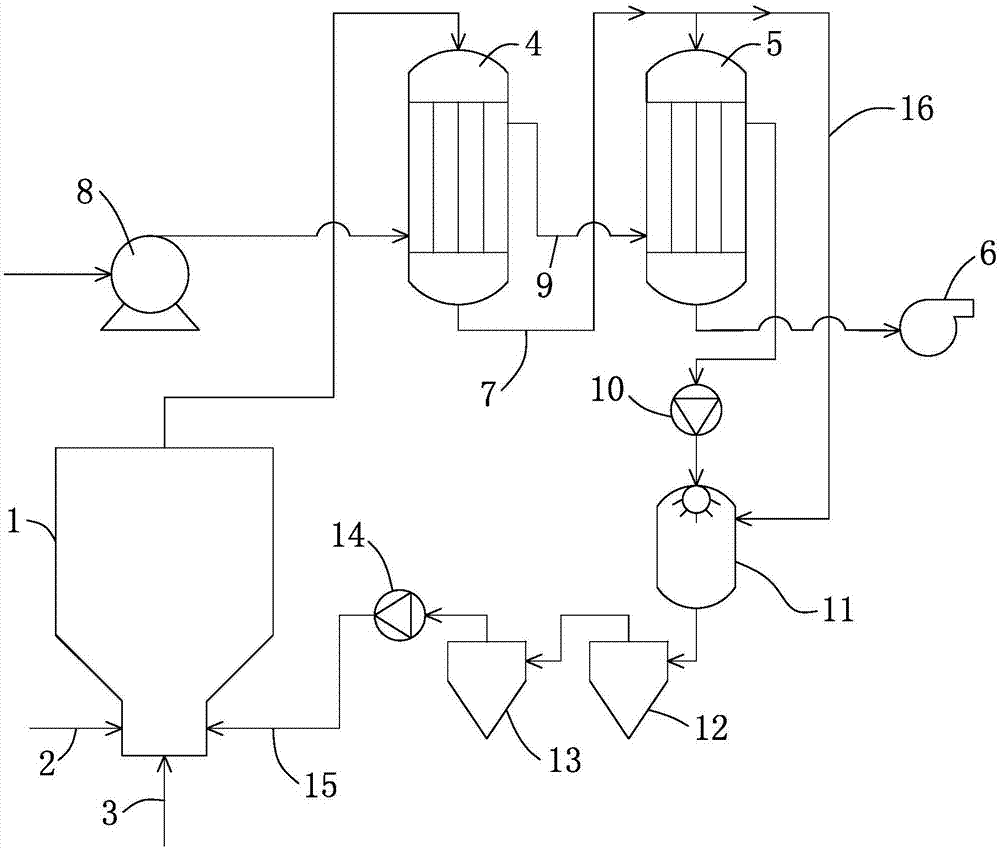

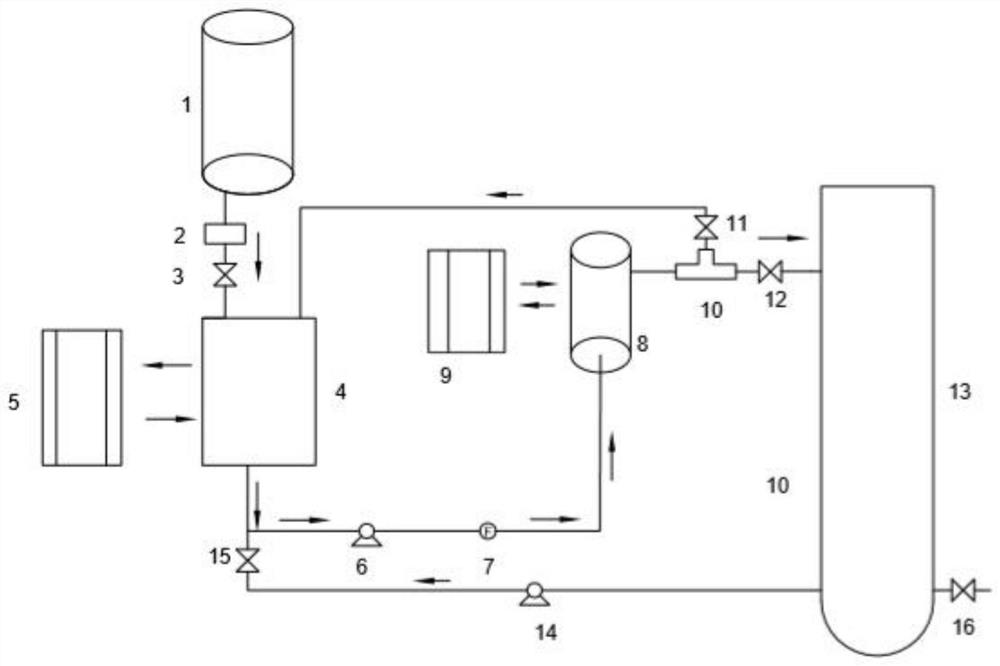

High-ammonia-nitrogen wastewater treatment method and device

PendingCN107963680ANo pollution in the processIncrease heatWater contaminantsWater/sewage treatment by heatingAmmoniacal nitrogenProcess engineering

The invention provides a high-ammonia-nitrogen wastewater treatment method and device and solves technical problems of poor treatment effects, poor environment protection effects and high cost in existing high-ammonia-nitrogen wastewater treatment. Salt-containing high-ammonia-nitrogen wastewater is subjected to two-stage heat exchange by heat generated in hydrogen and air combustion, and heated wastewater is subjected to gas-solid separation to obtain double-salt solid used as a fertilizer; after a heat exchange process, ammonia-nitrogen-containing gas is mixed with hydrogen and air combustion flame to continue combustion at a certain temperature and decomposed into nitrogen and water, and part of furnace gas is exhausted through a draught fan after second-stage heat exchange. The high-ammonia-nitrogen wastewater treatment method and device can be widely applied to high-ammonia-nitrogen wastewater treatment.

Owner:山东众音化学科技有限公司

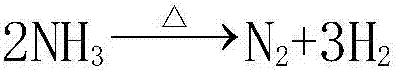

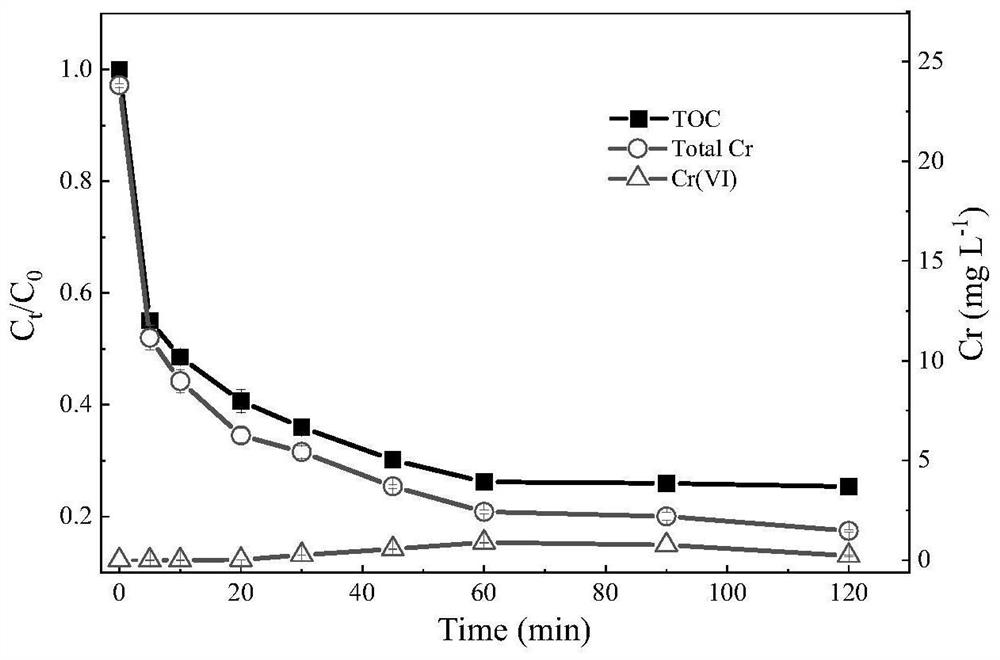

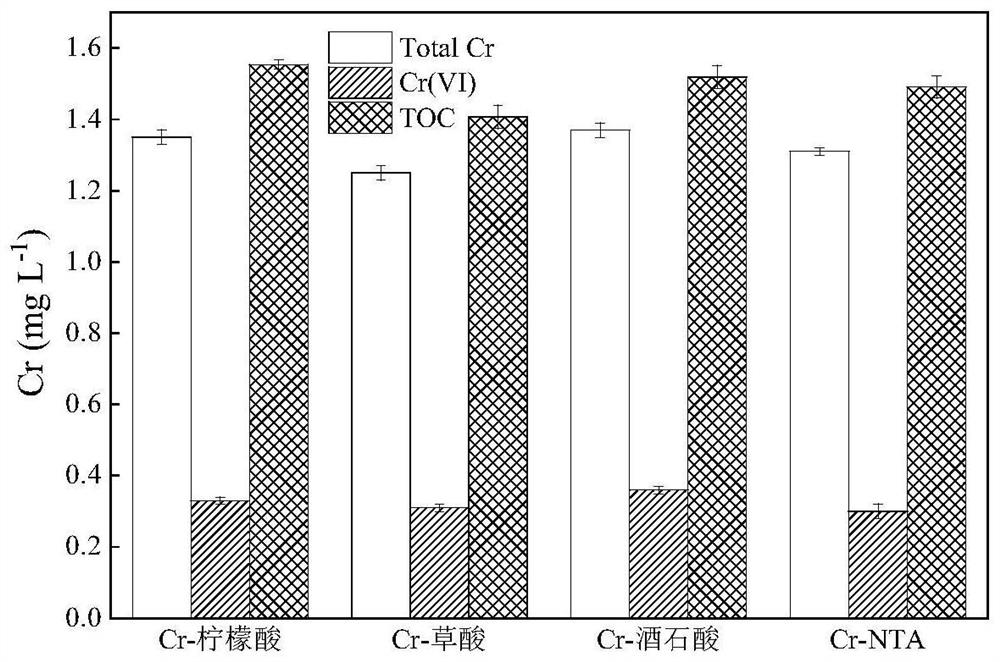

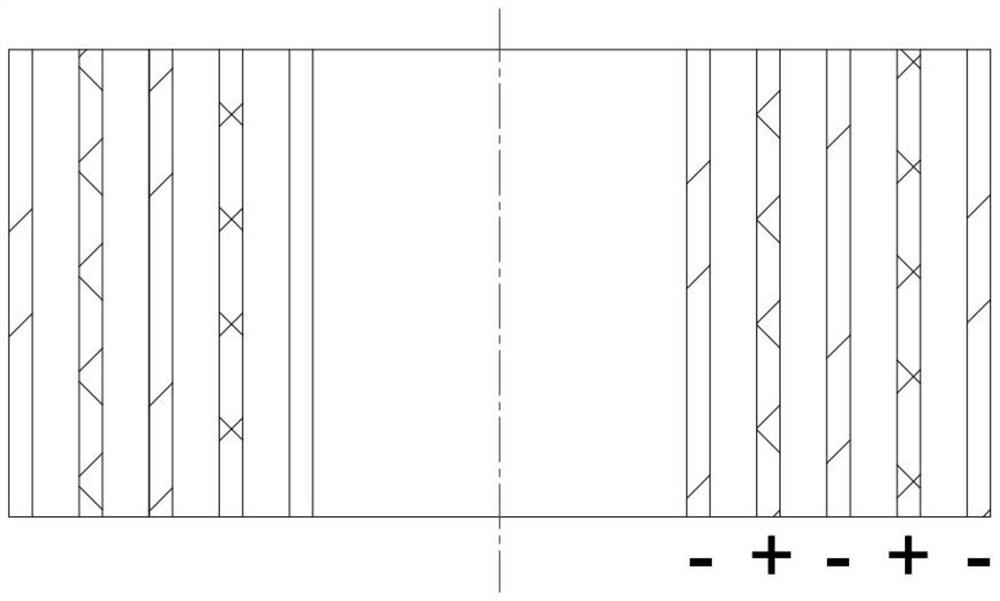

Method for treating organic complex chromium wastewater and synchronously controlling generation of hexavalent chromium

ActiveCN113072142ASimple and fast operationGood effectWater contaminantsProcess efficiency improvementSludgeEngineering

The invention discloses a method for treating organic complex chromium wastewater and synchronously controlling generation of hexavalent chromium, and belongs to the field of wastewater treatment. The method comprises the following steps: adding a trivalent chromium-containing complexing simulation solution or wastewater with adjusted pH into a reaction container, inserting a prepared anode and cathode into a reaction solution, and switching on a power supply; continuously aerating a mixed gas of O2 and O3 into the reaction container through a microporous aeration head, and carrying out hydraulic stirring while aerating to ensure that the reaction is carried out uniformly; and after the reaction is carried out for 30-120 minutes, depositing / adsorbing chromium on the cathode and anode materials. While the organic complex chromium is efficiently cracked by utilizing H2O2 generated by the carbon-based material in cooperation with O3, the generation of hexavalent chromium is controlled through the combination of multiple actions such as electrogenerated H2O2 reduction, cathode electroreduction and anode electroadsorption, and finally the chromium is transferred to the electrode material in an electrodeposition or electroadsorption manner, so that the accumulation of Cr (VI) is greatly reduced, the generation of chromium sludge hazardous wastes is reduced, The treatment cost is greatly reduced, and green treatment of the organic complex chromium wastewater is realized.

Owner:WENZHOU UNIVERSITY

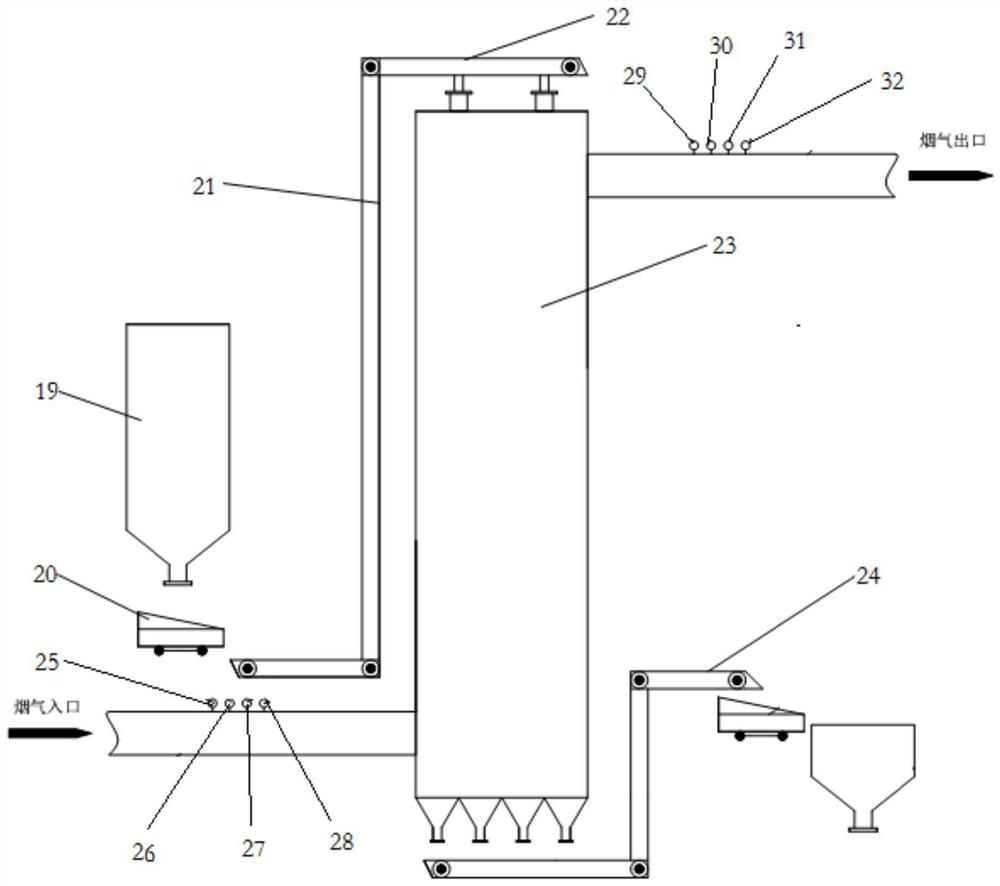

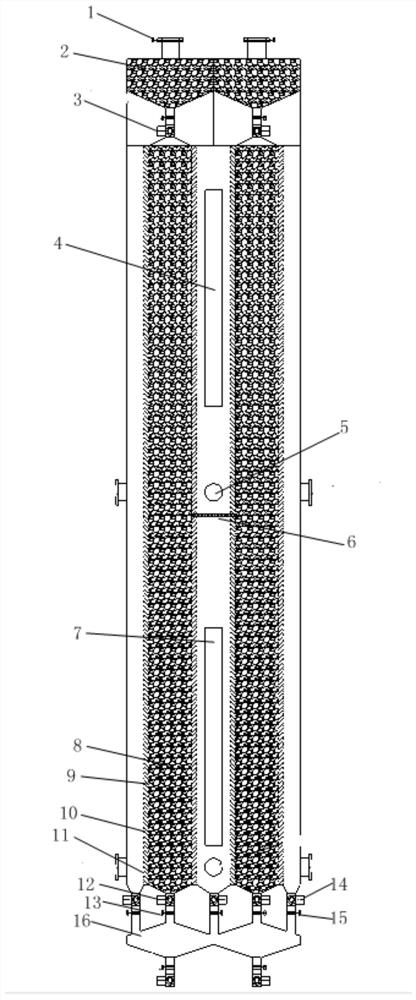

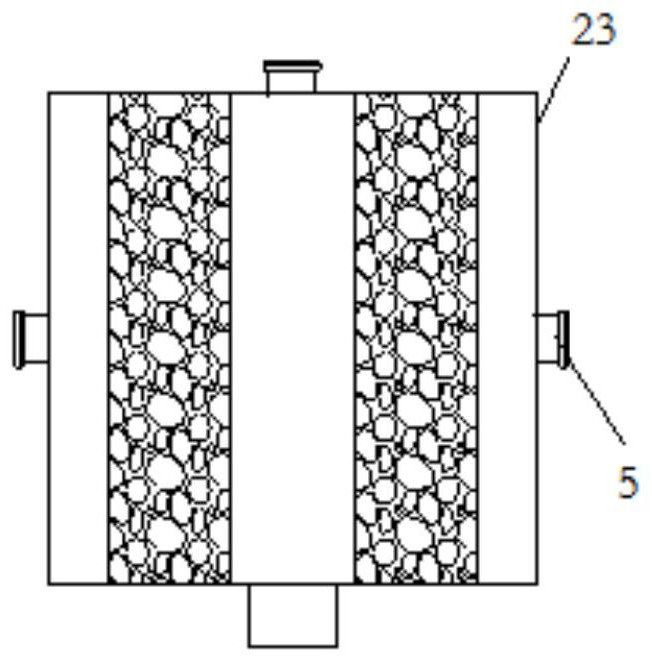

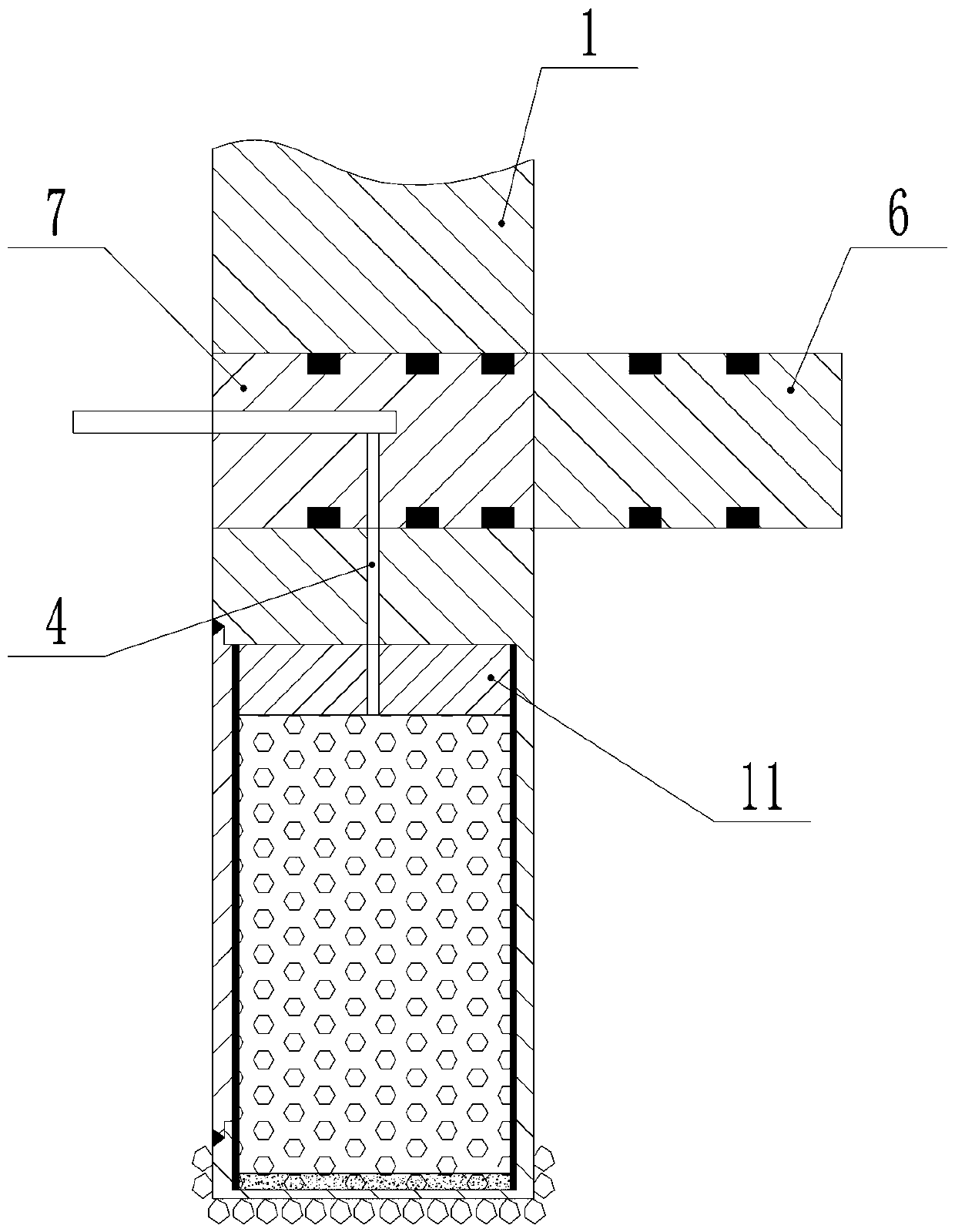

Moving bed device and process for dry flue gas desulfurization

PendingCN114272744AEfficient use ofRealize green processingDispersed particle separationThermodynamicsFlue gas

The invention provides a moving bed device and process for dry flue gas desulfurization. The moving bed device comprises a desulfurizing agent feeding unit, the desulfurizing agent conveying unit is connected with the desulfurizing agent feeding unit so as to convey a desulfurizing agent; the desulfurizing tower is provided with a flue gas inlet, a flue gas outlet, a desulfurizing agent feeding port and a desulfurizing agent discharging port, a partition blind plate is arranged between the flue gas inlet and the flue gas outlet, and the desulfurizing agent feeding port is connected with the desulfurizing agent conveying unit. Efficient utilization of the desulfurizing agent is realized through recycling of the desulfurizing agent; no wastewater or solid waste is generated, the pressure drop, the temperature drop and the occupied area are small, the energy consumption is low, dust and white can be removed, and green treatment of SOx is realized; the operation process is simple and the investment and operation cost is low.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Electrochemical treatment method of maleic anhydride acid water

ActiveCN113754141ARealize green processingAvoid cloggingWater treatment parameter controlElectrolysis componentsButanedioic acidAcid water

The invention discloses an electrochemical treatment method of maleic anhydride acid water, wherein the electrochemical treatment method comprises the steps: converting maleic acid in waste acid water generated in the process of producing maleic anhydride by oxidizing n-butane into succinic acid in a segmented electrolysis manner under the condition of not adding other chemical agents, and proposing a calculation formula for guiding the segmentation time. Cost increase caused by excessive segmentation and reactor blockage caused by succinic acid crystallization due to non-segmentation or too few segmentation are avoided, and green treatment of the acid water is realized.

Owner:ZHEJIANG UNIV OF TECH

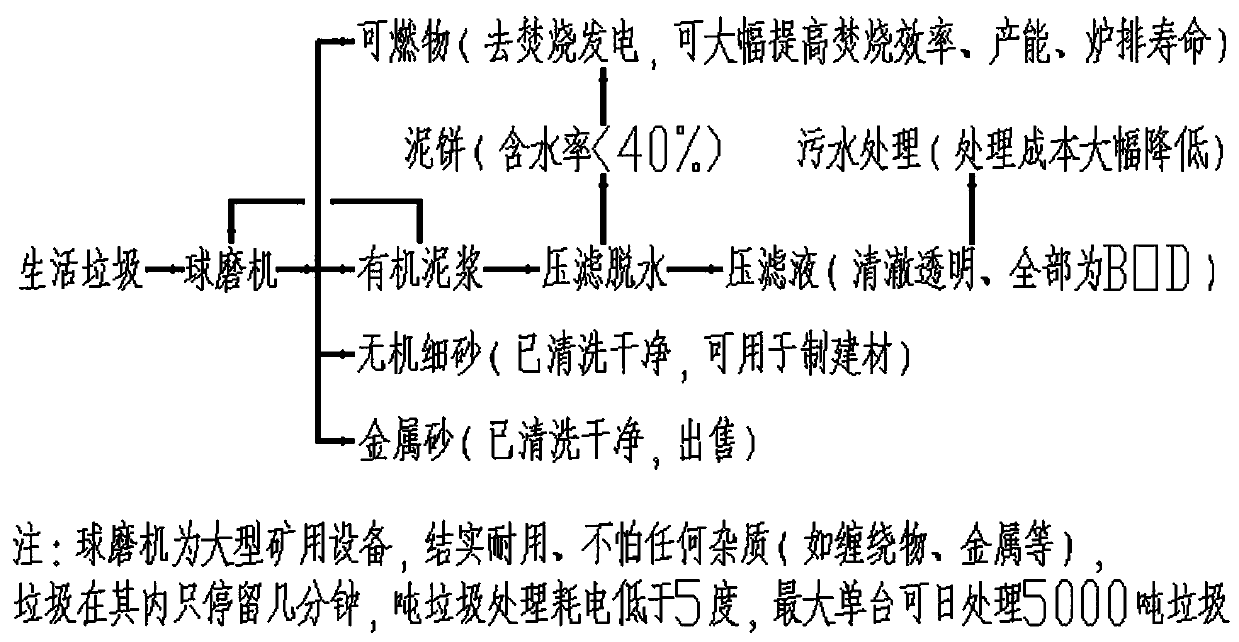

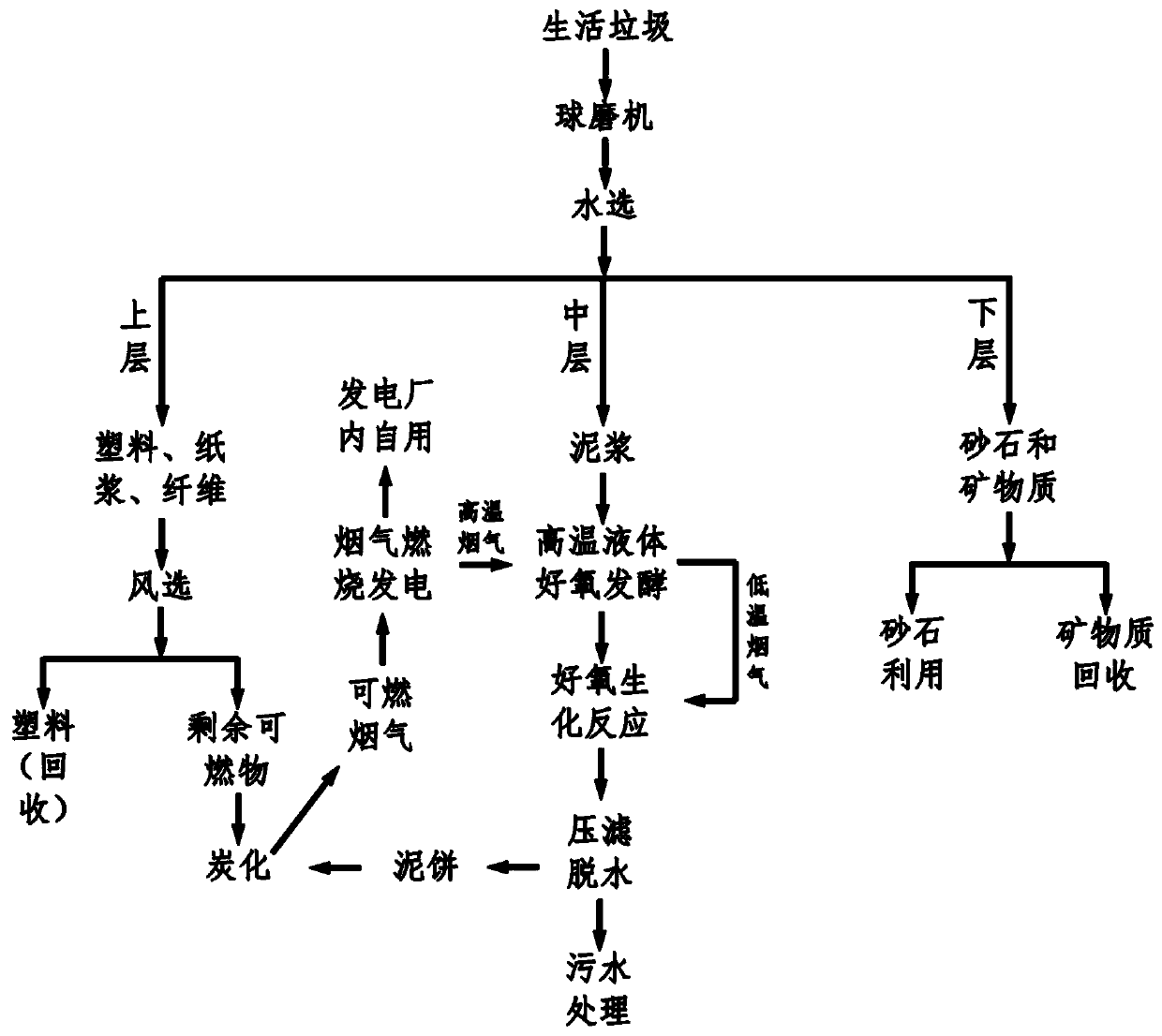

Garbage three-phase separation treatment process

InactiveCN110252781ARealize green processingImprove utilization efficiencyTransportation and packagingSolid waste disposalChemical industryClassification treatment

The invention relates to a garbage three-phase separation treatment process. The process effectively realizes the purpose of garbage separation, classification treatment and recycling facilitation. According to the technical scheme, the process comprises the following steps of 1 garbage crushing, 2 garbage sorting, 3 garbage slurry treating, 4 solid-liquid separation, and 5 waste gas treatment. Compared with an existing solid, liquid and gas three-phase separate treatment method, the process adopts a solid, liquid and gas synchronous treatment technology, a product after garbage treatment can be reused or recycled, the utilization efficiency of resources is improved, the green treatment of the garbage is realized, meanwhile, adopted equipment is commonly used equipment in the industry, the chemical industry and the like, the equipment is regular in operation and convenient to use, so that the method does not involve high-threshold technologies, so that the process does not involve excessively-high labor training cost, and the practicability is strong.

Owner:郑州同济环保工程有限公司

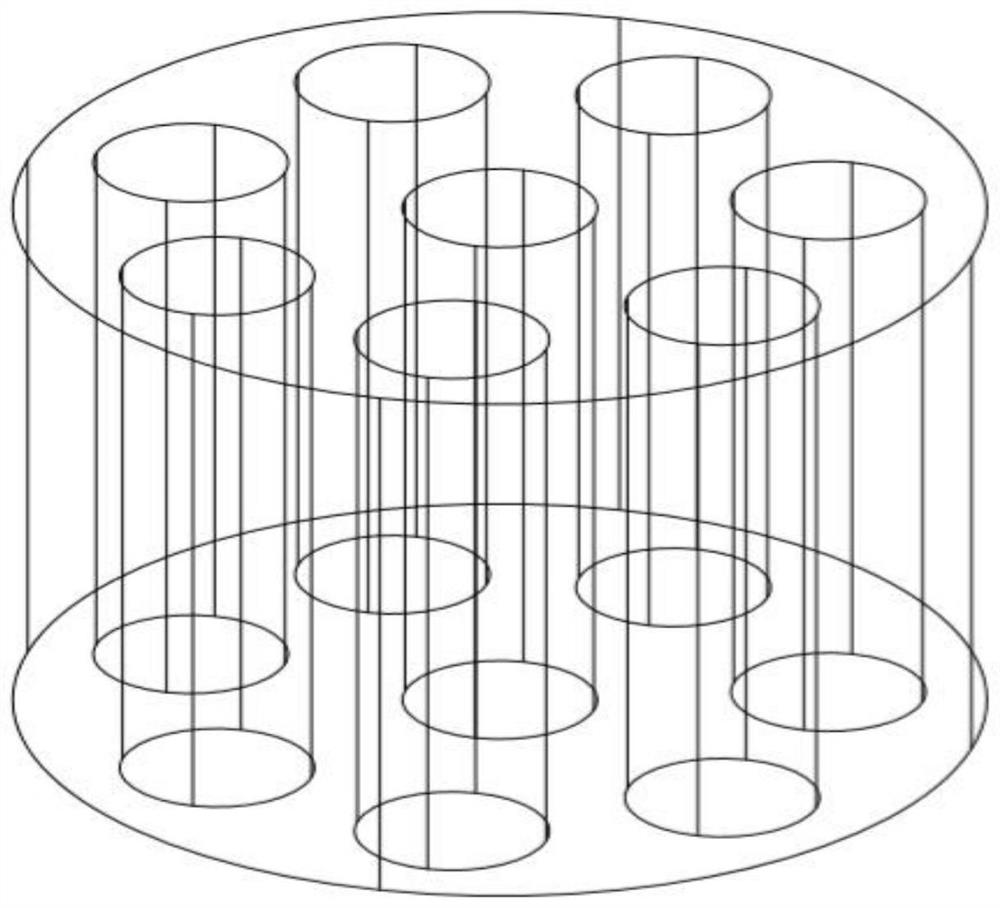

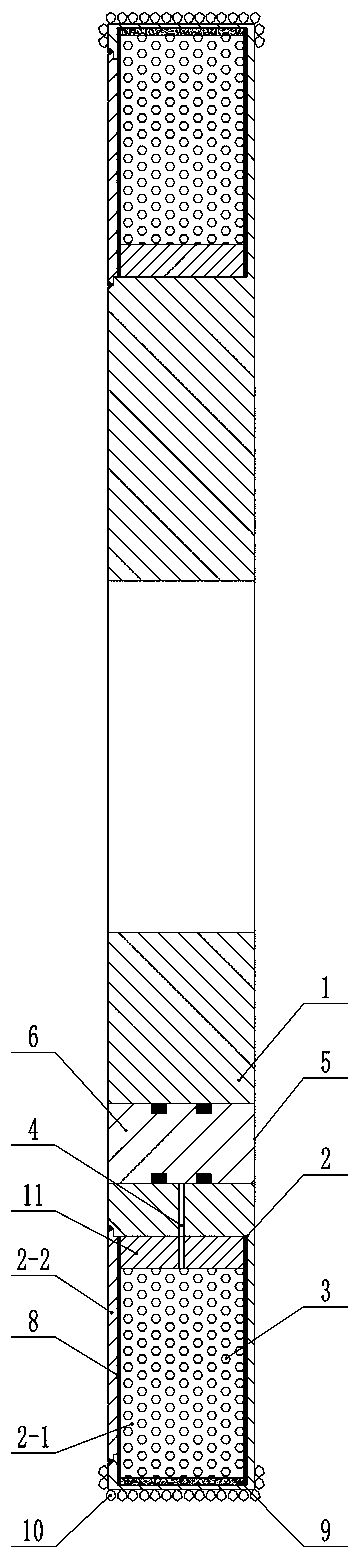

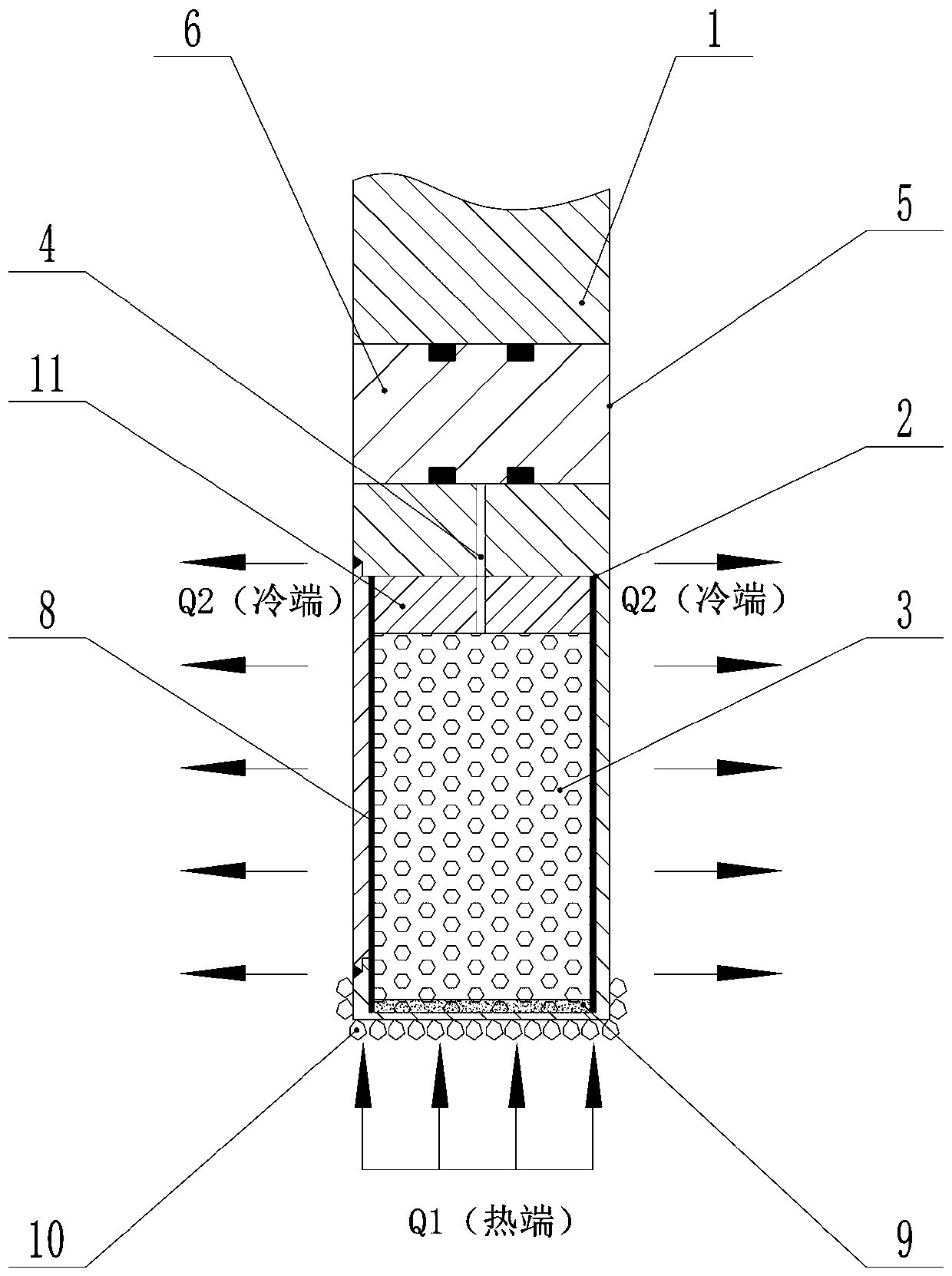

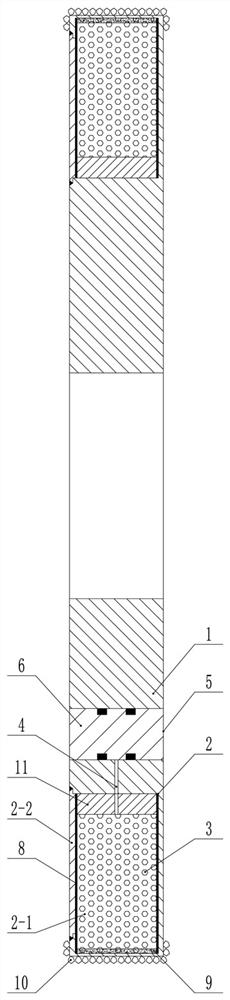

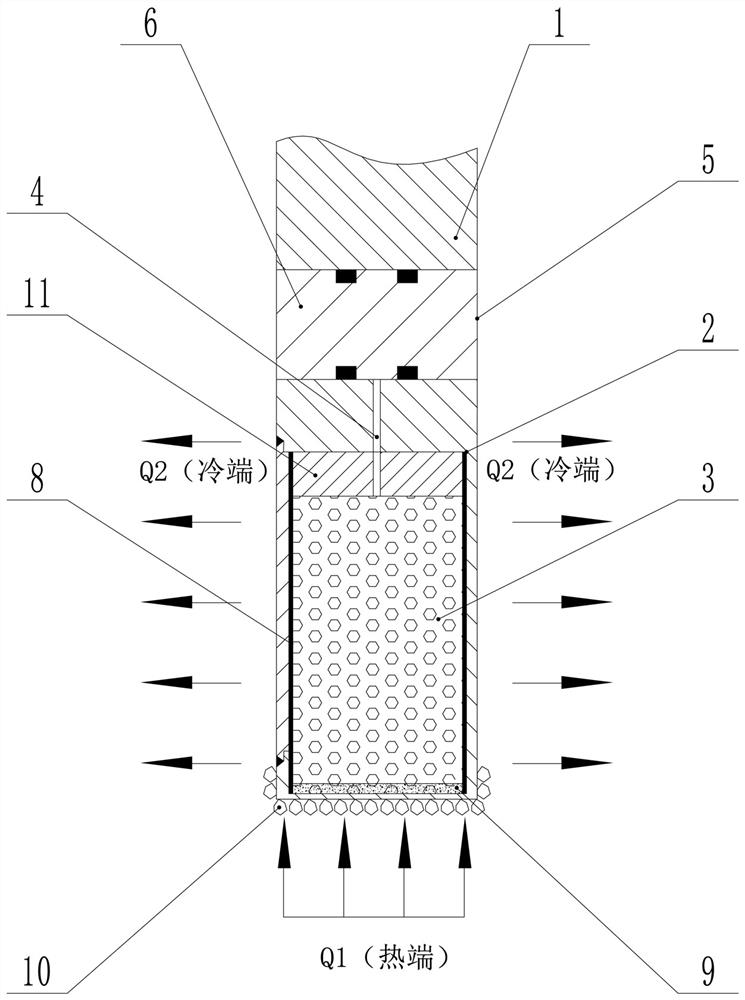

Novel high-thermal-conductivity phase-change heat storing superhard abrasive grinding wheel and preparation method thereof

ActiveCN109571292APhase change heat transfer efficiency improvementHighlight substantiveBonded abrasive wheelsGrinding devicesHeat conductingEngineering

The invention provides a novel high-thermal-conductivity phase-change heat storing superhard abrasive grinding wheel. The abrasive grinding wheel comprises a grinding wheel base body, wherein an annular pipe cavity is arranged in the position, close to the outer end, of the grinding wheel base body, annular foam metal fills the annular pipe cavity, and a gas-liquid phase-change heat transfer working medium is further arranged in the annular pipe cavity. An assembling gap is arranged between the foam metal and the inner side of annular tube cavity, metal filling blocks fill the assembling gap,and copper foil / graphite composite sheets are attached to the two side walls of the annular pipe cavity. The novel high-thermal-conductivity phase-change heat storing superhard abrasive grinding wheelhas the advantages that the heat conducting capability is high, the heat transfer performance is hardly influenced by the action of centrifugal force, and the grinding temperature can be effectivelycontrolled by using a small amount of cooling liquid.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

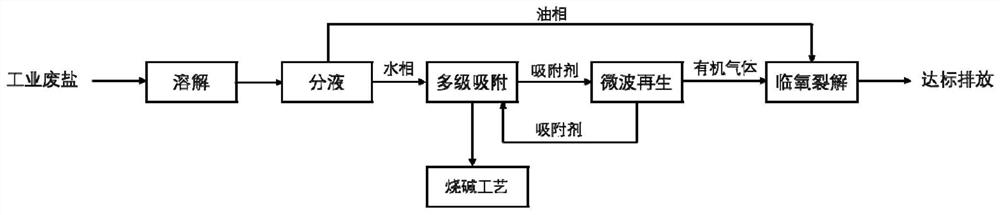

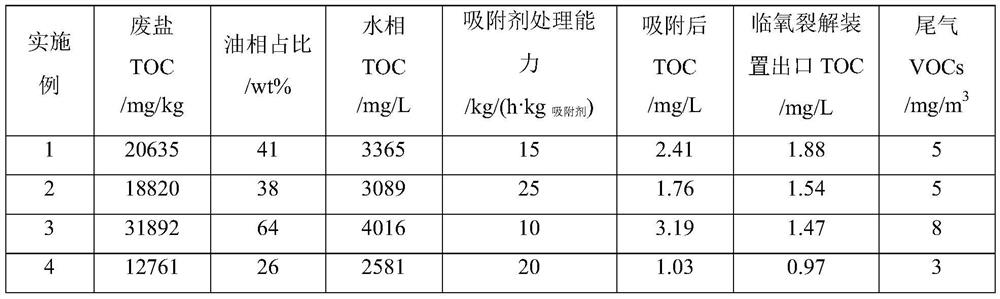

Comprehensive treatment and reutilization method for industrial inorganic waste salt containing organic pollutants

ActiveCN111847483ARealize green processingImprove processing efficiencyAlkali metal chloridesAlkali metal halide purificationAir atmospherePtru catalyst

The invention belongs to the field of environmental protection, and discloses a comprehensive treatment and reutilization method of industrial inorganic waste salt containing organic pollutants, whichcomprises the following steps of: dissolving, layering and separating the industrial waste salt to obtain an oil phase and a waste salt solution; enabling the waste salt solution to enter an adsorption unit for adsorption treatment, adsorbing organic matters by an adsorbent, and purifying to obtain an industrial salt solution; enabling the saturated adsorbent to enter a microwave regeneration device, performing microwave pyrolysis regeneration in a nitrogen atmosphere, enabling generated gas containing organic matters and an oil phase obtained by liquid separation to enter an oxygen crackingdevice, and performing catalytic oxidative cracking treatment in an air atmosphere under the action of a catalyst to realize deep purification. According to the method, various sodium chloride industrial waste salts can be systematically and efficiently treated, the TOC removal rate reaches 98% or above, and the final recovery rate of sodium chloride reaches 99%. By adopting the method to treat the industrial waste salt, purification treatment and resource reutilization of the waste salt can be realized, and the method has very high social and economic benefits.

Owner:NANJING UNIV OF TECH +1

Device and method for grinding and finishing coating of low-pressure turbine case of engine

InactiveCN114434266ALow trimming efficiencyImprove trimming accuracyGeometric CADGrinding feed controlDust controlCam

The invention discloses an engine low-pressure turbine case coating grinding and finishing device and method, and belongs to the technical field of engines, the engine low-pressure turbine case coating grinding and finishing device comprises a device body, a control device is fixedly installed on one side of the device body, and a dust removal device is fixedly installed on the other side of the device body; the top of one side of the device body is fixedly connected with an accompanying measuring device. According to the method, deformation data of the reference A of the inner ring of the casing coating is obtained in a non-contact measurement mode, data point cloud reflecting real deformation is obtained by processing the deformation data, a machining geometric curve is obtained through NURBS curve fitting, and then a coating grinding tool path driven by machining geometric characteristics is achieved through UG / CAM secondary development. NC codes are generated through post-processing to drive the device body to complete follow-up grinding and finishing of the casing coating, the finishing efficiency and finishing precision of the coating are improved, and meanwhile the cost and the labor intensity of workers are reduced.

Owner:天津仁爱学院

A combined cleaning vehicle for lawn leaves

InactiveCN104429647BImprove applicabilityHigh raking efficiencyHops/wine cultivationTurf growingCircular discEngineering

The invention discloses a combine cleaning vehicle for leaves on lawns. The combine cleaning device comprises front wheels, rear wheels, handlebars, a frame, a main collecting device, a simulated stripping device, a driving device, a recycling and compressing device and a weeding device. The main collecting device comprises a big roller, a small roller, a main conveying belt, elastic rake teeth, front rake corner adjusting devices, rear rake corner adjusting devices and accelerating devices. The front rake corner adjusting devices comprise suspending rods, adjusting screw tubes and supporting rods. The rear rake corner adjusting devices comprise pawl turnplates, ratchet shifting shanks, rotating shafts, torsion springs, pawls and pawl fixing blocks. The simulated stripping device comprises a large cam, a stripping comb, first connecting rods, second connecting rods and rotating discs. According to the arrangement, the elastic rake teeth are high in adaptability to the lawns with different conditions; the simulated stripping device adopts a design simulating hand stripping movements; by the use of the recycling and compressing device, garbage including leaves is processed environmentally friendly, and wide-range application is available to the schools, the parks and the like.

Owner:ANHUI UNIV OF SCI & TECH

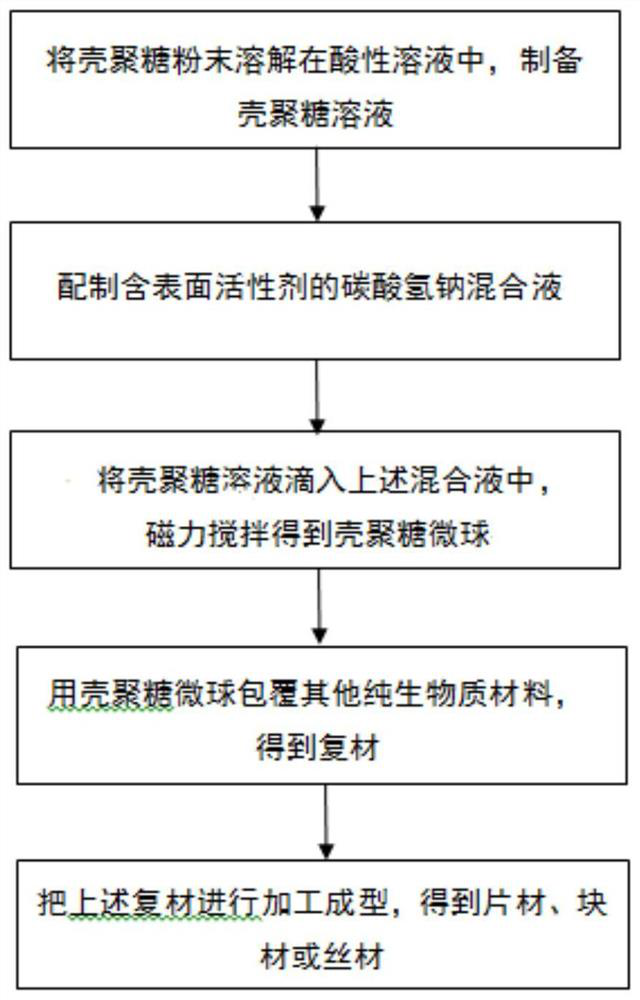

A kind of method for plasticizing biomass composite material with low melting point chitosan microspheres

The invention belongs to the field of polymer material preparation, and discloses a preparation method of a low-melting-point chitosan microsphere plasticized biomass composite material. The method comprises the following steps: (a) selecting an acidic solution to dissolve chitosan powder to form a chitosan solution, adding an alkaline solution into the chitosan solution to form a mixed solution,adjusting the pH value of the mixed solution to be 7 or above, and stirring the mixed solution until nano-scale chitosan spherical particles are separated out; and (b) mixing the nano-scale chitosan spherical particles with a biomass material, so that the chitosan is coated on the surface of the biomass material to form a biomass composite material, wherein the phenomenon that the biomass materialis agglomerated and is not melted during melt processing is avoided by the small-size effect of the nano-scale chitosan spherical particles. According to the method, the chitosan particles are nanocrystallized, the melting point of the chitosan particles is reduced, agglomeration of the chitosan biomass composite material during melt processing is avoided, and the mechanical property of the chitosan biomass composite material is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

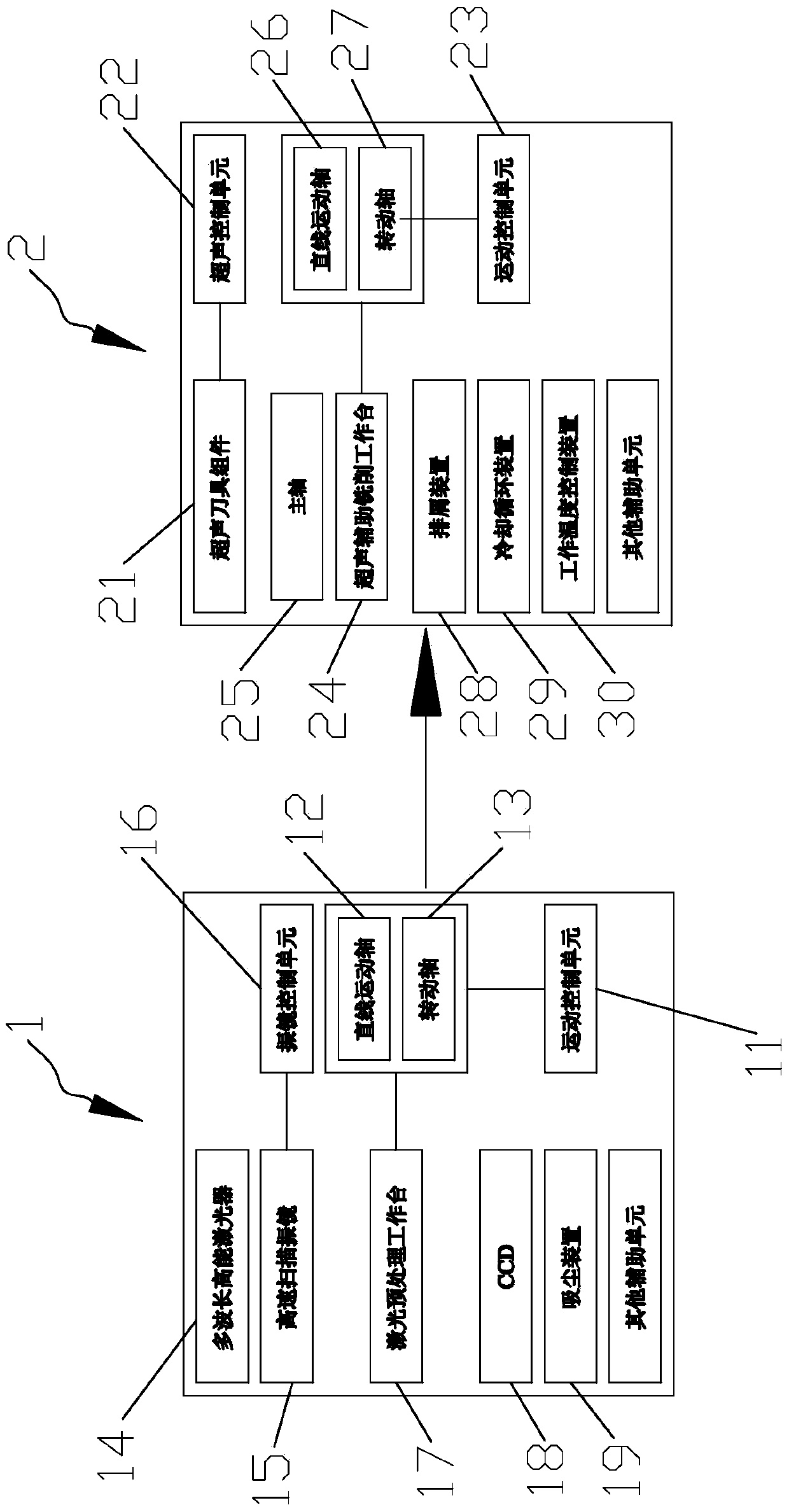

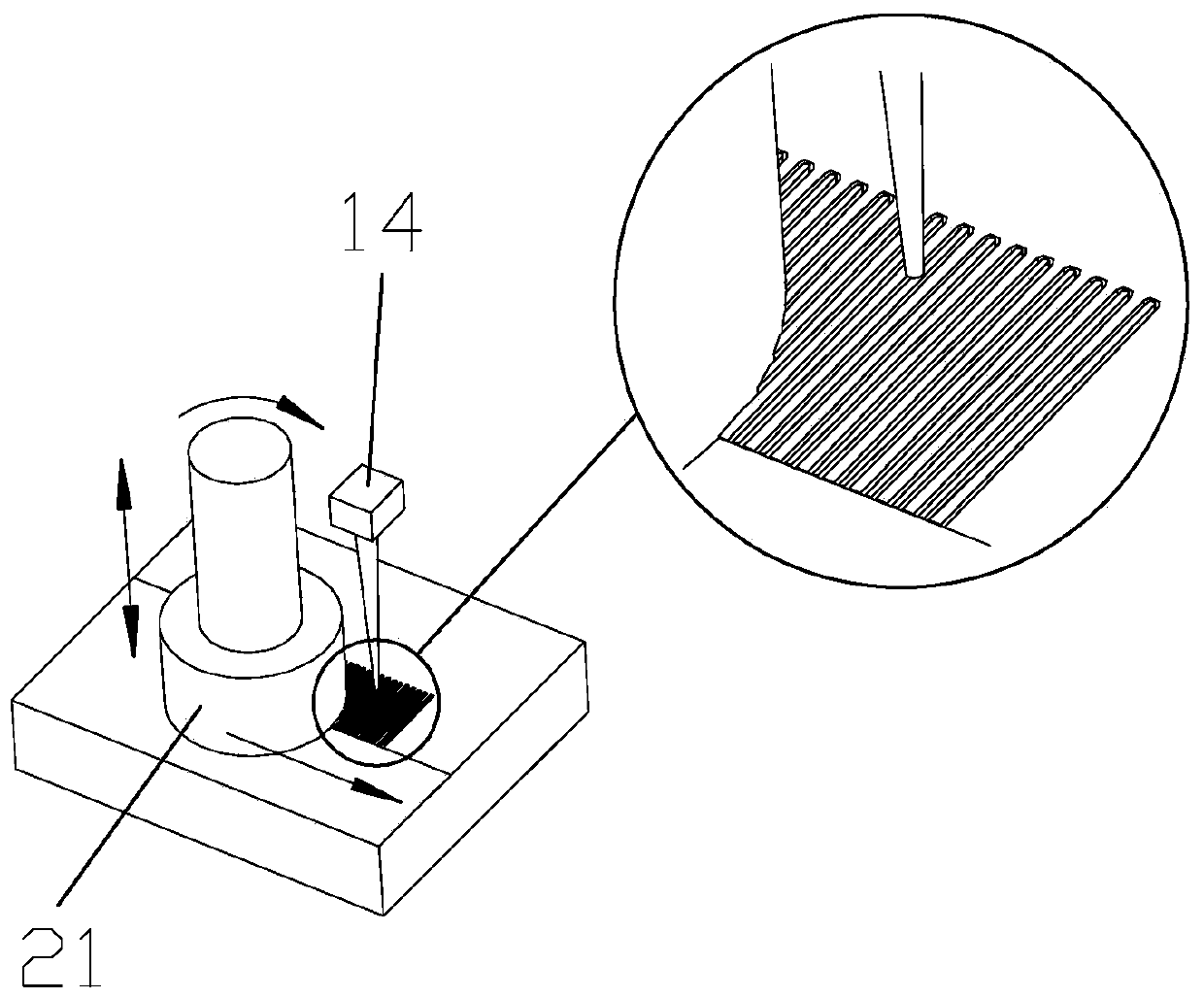

A laser prefabricated micro-texture assisted ultrasonic milling process method and processing system

ActiveCN106271493BImprove machinabilityReduce processing difficultyOther manufacturing equipments/toolsUltrasonic vibrationMicro texture

The invention provides an auxiliary ultrasound milling technological method for laser micro-texture prefabricating. The technological method comprises a laser pretreatment step and an ultrasound auxiliary milling step. The laser pretreatment step comprises the sub-steps that a position parameter of a to-be-machined material is adjusted, so that the position parameter of the to-be-machined material is in accordance with a first predetermined position parameter; and a laser beam is generated, and the spatial posture, corresponding to the to-be-machined material, of the laser beam is adjusted. The ultrasound auxiliary milling step comprises the sub-steps that the position parameter of the to-be-machined materials subjected to laser pretreatment is adjusted, so that the position parameter of the to-be-machined material is in accordance with a second predetermined position parameter; ultrasound vibration of an ultrasound cutter assembly is controlled; the ultrasound cutter assembly is rotated, and the rotation freedom degree, corresponding to the to-be-machined material subjected to laser pretreatment, of the ultrasound cutter assembly is adjusted; and the position relation between the ultrasound cutter assembly and the to-be-machined material subjected to laser pretreatment in the X direction, the Y direction and the Z direction is changed. The invention further relates to an auxiliary ultrasound milling machining system for laser micro-texture prefabricating.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing composite copper catalyst by recycling organic silicon waste contacts

InactiveCN102614885BRealize green processingAvoid secondary pollutionGroup 4/14 element organic compoundsChemical recyclingPartial oxidationCopper oxide

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

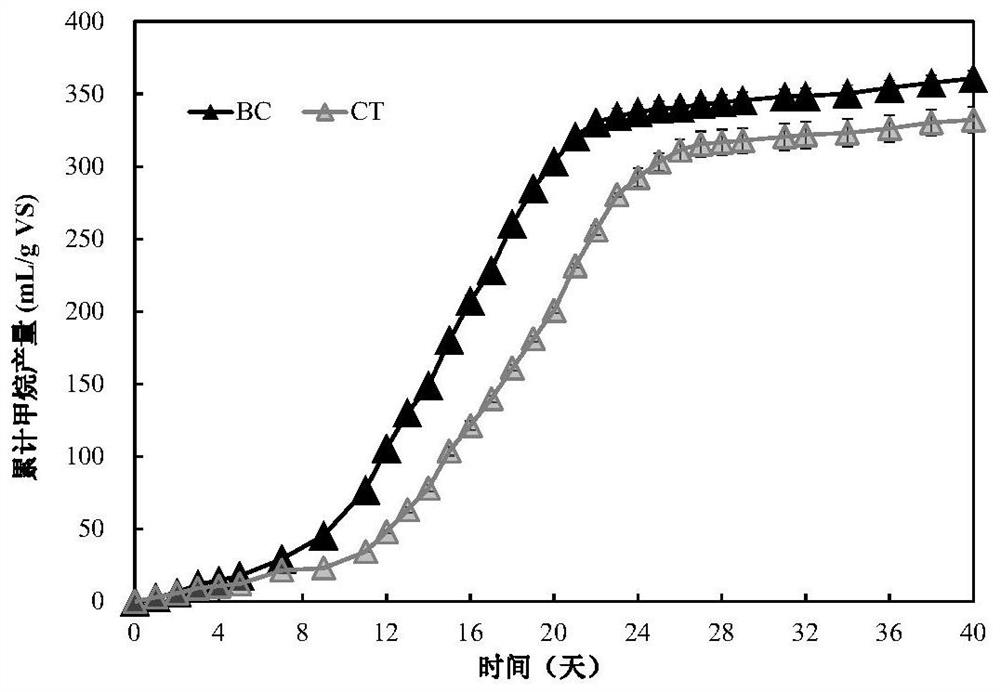

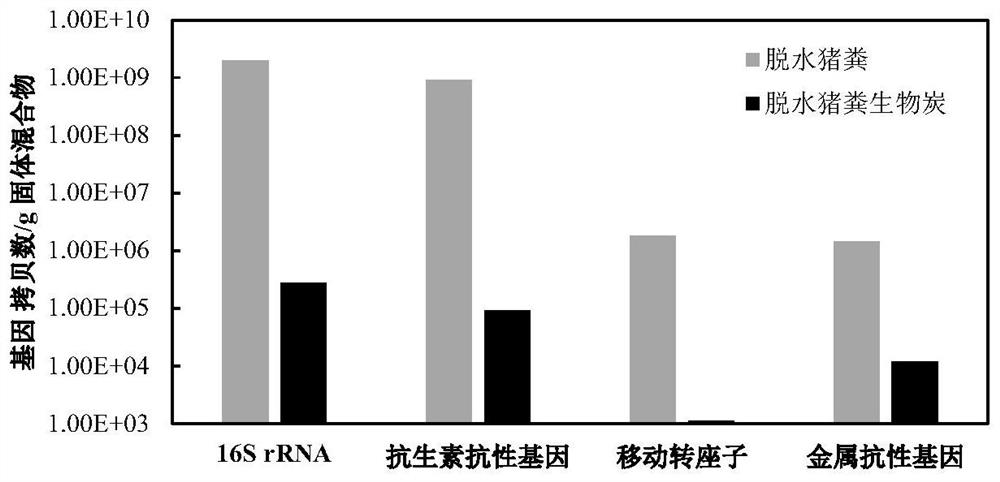

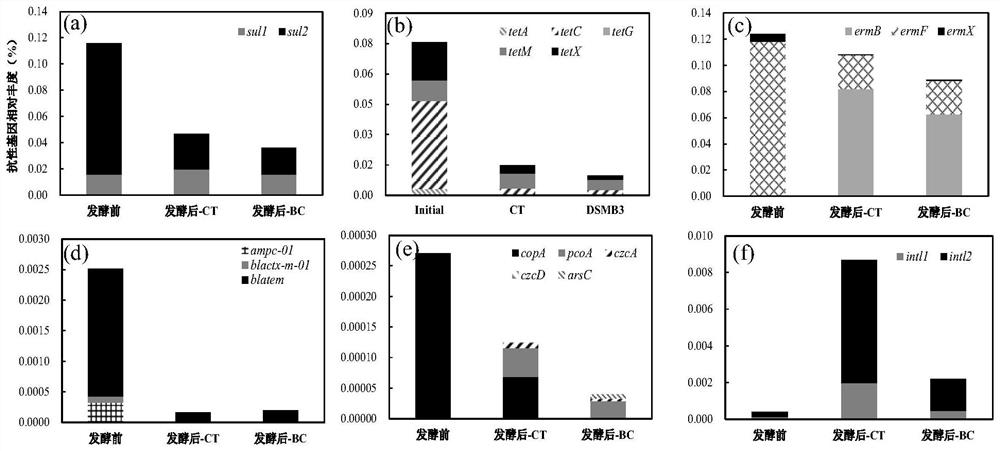

Resource treatment method for pig farm waste

PendingCN114314825AImprove resource efficiencyEasy to operateSludge treatment by pyrolysisByproduct vaporizationBiotechnologyPig farms

The invention discloses a pig farm waste recycling treatment method. The method comprises the following steps: step 1, drying dehydrated pig manure produced in a pig farm, and performing pyrolysis treatment at 300 DEG C to prepare dehydrated pig manure biochar; step 2, applying the dehydrated pig manure biochar to an anaerobic fermentation system of swine wastewater for anaerobic fermentation treatment; 3, evaluating the promotion effect of the addition of the dehydrated pig manure biochar on the fermentation efficiency of the pig manure wastewater by monitoring the soluble COD, the volatile fatty acid concentration and the biogas yield in the anaerobic fermentation process; the abundance of the resistance genes contained in the dehydrated pig manure before and after pyrolysis treatment is measured, and the reduction effect of the charcoal prepared through pyrolysis on the resistance genes in the dehydrated pig manure is evaluated; by comparing the abundance of the resistance genes in the swine wastewater fermentation liquor before and after the addition of the dehydrated pig manure biochar, the reduction effect of the addition of the dehydrated pig manure biochar on the swine wastewater fermentation resistance genes is evaluated. The method realizes green treatment of two kinds of pig farm wastes.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Metal ceramic cutter with gradient structure and preparation method thereof

ActiveCN101838766BImprove high temperature oxidation resistanceHigh hardnessOxidation resistantMechanical property

The invention discloses a metal ceramic cutter with a gradient structure and a preparation method thereof, belongs to a metal ceramic material, and solves the problem that the conventional method for preparing the metal ceramic cutter has higher cost and lower comprehensive mechanical property. The metal ceramic cutter of the invention is characterized in that a hard phase in finally generated phases is (Ti, W, Mo, Ta, Nb) (C, N) and a bonding phase is Ni, wherein the hard phase and the bonding phase are in symmetrical gradient distribution from a surface layer to a middle layer. The method of the invention sequentially comprises the steps of raw material preparation and mixing, layer-by-layer paving and compression molding, degreasing and vacuum sintering. The method is simple and has low cost; the surface hardness of the manufactured metal ceramic cutter is 92.5 to 92.8HRA, the bending strength is more than or equal to 2,000MPa, and the fracture toughness KIC is more than or equal to 12.0MPa.m<1 / 2>; and the metal ceramic cutter has the advantages of good high-temperature red hardness, abrasion resistance, chemical stability and impact toughness resistance and strong high-temperature oxidation resistance, is suitable for high-speed efficient cutting and processing and dry cutting, and can reduce the using amount of cutting fluid or does not use cutting fluid.

Owner:HUAZHONG UNIV OF SCI & TECH

Low-temperature gas-phase multi-element strengthening method preset with three-stage process

ActiveCN106048516AHigh hardnessAnti-oxidation energy saving and environmental protectionSolid state diffusion coatingMulti elementHeating furnace

The invention discloses a low-temperature gas-phase multi-element strengthening method preset with a three-stage process. The low-temperature gas-phase multi-element strengthening method preset with the three-stage process comprises the following steps: (1) performing sand blasting or pickling on a to-be-treated workpiece, and putting the to-be-treated workpiece subjected to sand blasting or pickling into a clamp; (2) putting the clamp into a heating furnace for heat treatment: (21) increasing a temperature in the heating furnace to 350 DEG C, preserving the heat for 20-30 minutes, warming, and introducing ammonia gas into the heating furnace; (22) when the temperature is increased to 500-560 DEG C, introducing ammonia gas and a permeating agent A into the heating furnace, preserving the heat for 1-3 hours and continuously warming; (23) when the temperature is increased to 570-670 DEG C, introducing the ammonia gas and the permeating agent A into the heating furnace again, preserving the heat for 0.5-1.5 hours, and cooling; and (24) when the temperature is reduced to 500-520 DEG C, introducing ammonia gas and a permeating agent B into the heating furnace, preserving the heat for 1-3 hours, and then, cooling and discharging. The low-temperature gas-phase multi-element strengthening method preset with the three-stage process solves the problem that temperature range is relatively narrow, and can carry out alpha-Fe high-temperature-section surface modifying and strengthening treatment at a temperature being 500-670 DEG C.

Owner:赵海军

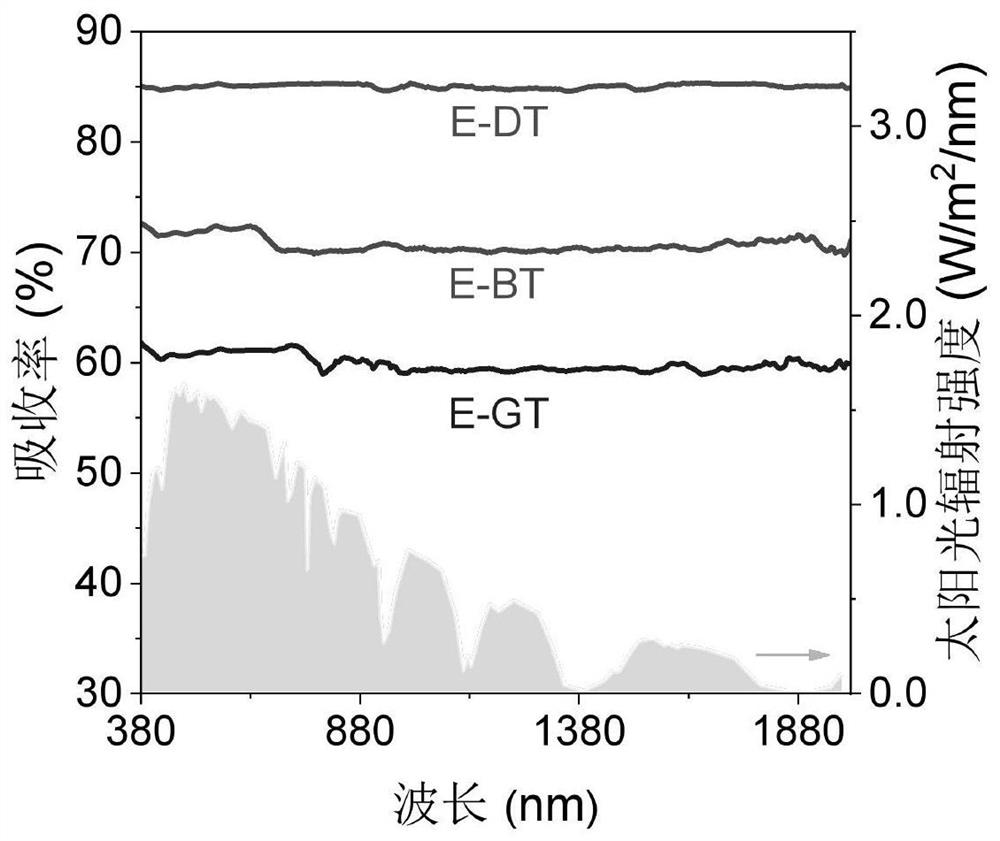

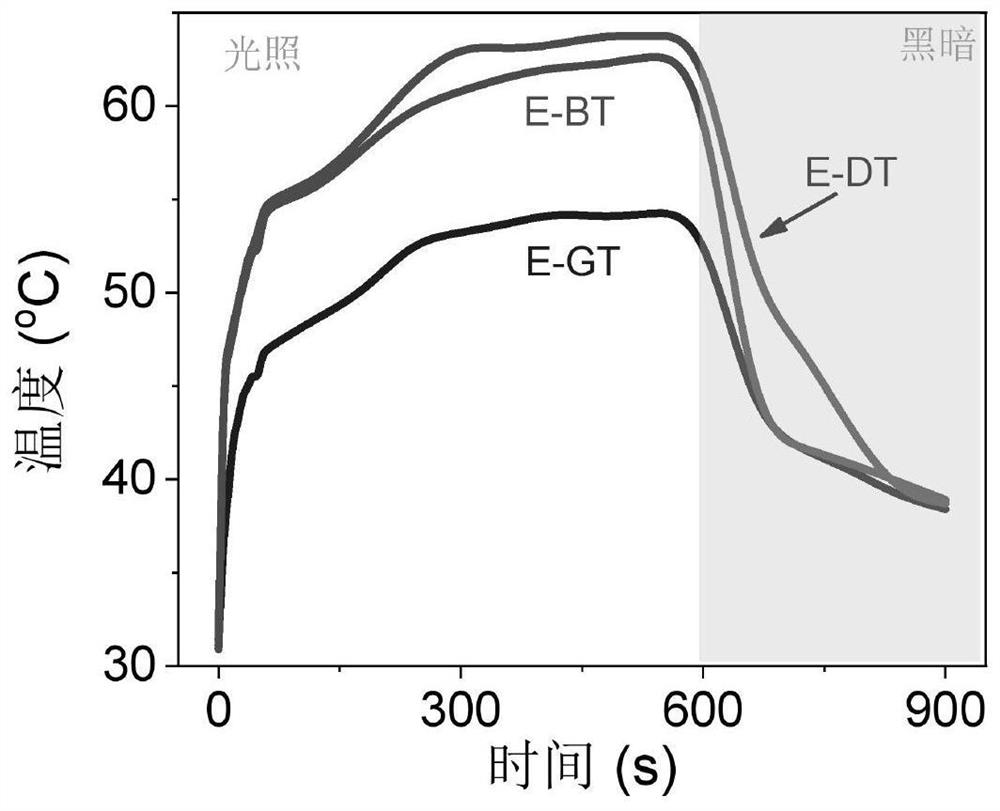

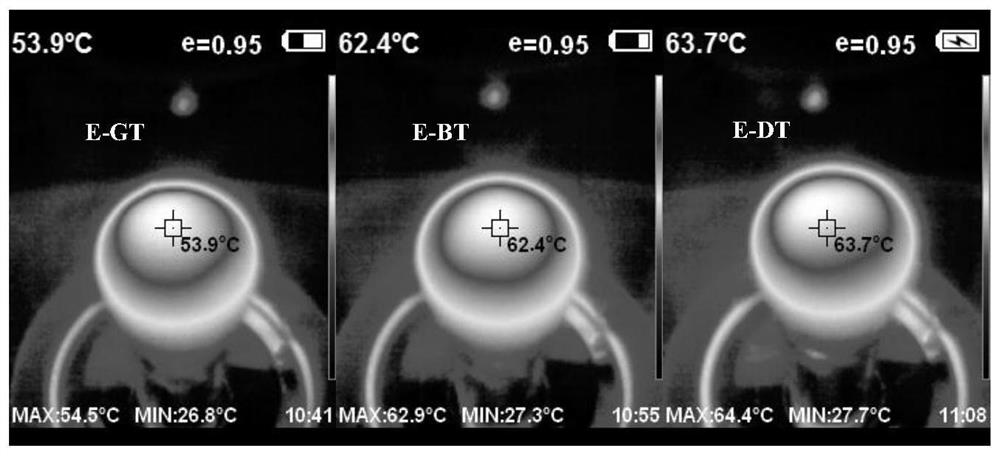

Preparation method of photo-thermal seawater desalination film based on tea and photo-thermal seawater desalination film

PendingCN113181778ARealize multiple recyclingLow priceGeneral water supply conservationSeawater treatmentMaterials scienceChemical engineering

The invention provides a preparation method of a tea-based photo-thermal seawater desalination film and the photo-thermal seawater desalination film prepared by the method. The method comprises the following steps: (1) drying tea, and grinding into tea powder; (2) dispersing the tea powder into a solvent to obtain a dispersion liquid; and (3) carrying out vacuum filtration on the dispersion liquid to a filter membrane to obtain the photo-thermal seawater desalination membrane. According to the method provided by the invention, the raw materials are cheap and easy to obtain, the membrane preparation operation is simple and convenient, and the prepared membrane material can be recycled for multiple times and has industrial practicability.

Owner:HUBEI UNIV OF TECH

A new type of superhard abrasive grinding wheel with high thermal conductivity phase change heat storage and preparation method thereof

ActiveCN109571292BNovel structureSimple preparation processBonded abrasive wheelsGrinding devicesHeat conductingCopper foil

The invention provides a novel high-thermal-conductivity phase-change heat storing superhard abrasive grinding wheel. The abrasive grinding wheel comprises a grinding wheel base body, wherein an annular pipe cavity is arranged in the position, close to the outer end, of the grinding wheel base body, annular foam metal fills the annular pipe cavity, and a gas-liquid phase-change heat transfer working medium is further arranged in the annular pipe cavity. An assembling gap is arranged between the foam metal and the inner side of annular tube cavity, metal filling blocks fill the assembling gap,and copper foil / graphite composite sheets are attached to the two side walls of the annular pipe cavity. The novel high-thermal-conductivity phase-change heat storing superhard abrasive grinding wheelhas the advantages that the heat conducting capability is high, the heat transfer performance is hardly influenced by the action of centrifugal force, and the grinding temperature can be effectivelycontrolled by using a small amount of cooling liquid.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

Dyeing enzyme for improving pilling resistance of polyester-cotton knitted fabric and preparation method of dyeing enzyme

InactiveCN110306346AImprove wettabilityLittle power lossAbrasion resistant fibresVegetal fibresBiomassChemistry

The invention discloses dyeing enzyme for improving pilling resistance of a polyester-cotton knitted fabric, and belongs to the technical field of textile dyeing. The dyeing enzyme comprises, by weight, 5-15 parts of heat-resistant weak-acidic pectinase, 5-15 parts of cutinase, 5-25 parts of wide pH (potential of hydrogen) cellulose, 1-5 parts of C21 monocyclic binary acid salt, 10-30 parts of biomass polyoxy alkyl ether, 1-5 parts of N-alkyl phthalimide and 40-70 parts of water. According to the dyeing enzyme for improving pilling resistance of the polyester-cotton knitted fabric, refining and oil removing, polishing and polyester dyeing can be completed once, energy, water and time are saved, emission is reduced, energy conservation and emission reduction requirements of green printing and dyeing are met, COD (chemical oxygen demand) content of waste water can be reduced, and a product and a printing and dyeing process are innovated.

Owner:GUANGDONG ZHAN FENG FINE CHEM CO LTD

Chamfering machine cutter

The invention provides a chamfering machine cutter which comprises a cutter handle and a plurality of cutter grains used for cutting workpieces. One end of the cutter handle is connected with the output end of a motor, the other end of the cutter handle is provided with an assembling groove used for assembling the cutter grains, and the cutter grains are detachably arranged in the assembling groove; due to the split type design, a user can conveniently replace the cutter grains; and in addition, the assembling groove can be provided with turning tool grains, rough boring tool grains, rough tool grains, C angle tool grains, R angle tool grains and finish milling tool grains, and the chamfering machine cutter has the advantages that customers can select more targeted and suitable tool grains according to the requirements of machined parts, meanwhile, waste tool grains used on a machine tool can be used as the tool grains, green machining is achieved, and the consumable cost is saved. A customer can select a rolling bearing of phi 7 / phi 9 / phi 13 / phi 15 / phi 17 / phi 19 / phi 24 according to the diameter of a round hole of a machined part.

Owner:东莞市航元五金工具有限公司

A precision crushing device for rare earth hot ore

The invention provides an accurate crushing device for rare earth hot ore, and belongs to the field of crushing equipment. The accurate crushing device for rare earth hot ore comprises a preheating chamber, an ultrasonic chamber, an impact chamber, a primary breaking chamber, a fine crushing chamber and a screening device, wherein the preheating chamber, the ultrasonic chamber, the impact chamber,the primary breaking chamber and the fine crushing chamber are sequentially connected in sequence from left to right, and the screening device is arranged below a discharging port of the fine crushing chamber. According to the device, the ultrasonic chamber is arranged, so that the size of the rare earth ore can be preliminarily determined in advance, and particles with fixed sizes can be more easily formed in the subsequent impact and crushing processes; through the cooperation of the primary breaking chamber, the fine crushing chamber and the screening device, so that the control over the size consistency of ore particles is realized; the heat in the primary breaking process and the fine crushing process are recycled, so that the green treatment of the heat energy is realized; and the accurate crushing device has the advantages of being high in ore particle size consistency, low in pulverization rate, green and clean and the like.

Owner:UNIV OF SCI & TECH BEIJING

Method and application of one-step conversion of shrimp and crab shells to prepare water-soluble small molecule active substances

ActiveCN111647026BProcess technology green environmental protectionSafe and efficient process technologyBiocidePlant growth regulatorsCellulosePhosphoric acid

The present invention "a method for one-step conversion of shrimp and crab shells to obtain water-soluble small molecule active substances and its application" relates to environmental protection processing technology, and is characterized in that the organic and inorganic matrix materials represented by shrimp and crab shells are crushed to a particle size smaller than 20 mesh, dissolve with polyphosphoric acid-choline chloride deep eutectic solvent composite system at 80°C-95°C under stirring conditions for 2-4 hours; under heat preservation conditions, add 0.1-1% catalyst aqueous solution to catalyze degradation for 1-3 hours A steady state water-soluble active substance solution is obtained. The polyphosphoric acid-choline chloride deep eutectic solvent complex system used in it has good solubility, and has good solubility to cellulose, protein and inorganic salts in the organic-inorganic mixed matrix, and can dissolve shrimp in one step. Crab shells are used to prepare steady-state water-soluble active substance solutions rich in amino-oligosaccharins, soluble calcium elements, soluble small molecule peptides, and amino acids, which can be prepared in a low-cost, environmentally friendly, and high-efficiency way using organic and inorganic matrix waste as raw materials. A product for many uses.

Owner:王士奎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com