Method for treating organic complex chromium wastewater and synchronously controlling generation of hexavalent chromium

An organic complexation and synchronous control technology, which is applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of easily accumulating hexavalent chromium to remove Cr, reduce treatment costs, and cumbersome, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method of treating organic complexed chromium wastewater and synchronously controlling the generation of hexavalent chromium in this embodiment uses tap water to prepare Cr-EDTA wastewater with a concentration of 0.2mmol / L, adjusts pH to 3±0.02 by HCl / NaOH, and current density 15mA / cm 2 , the dosage of ozone is 7.4mg / L, the self-made cathode and anode electrodes are 5×8cm titanium mesh, the material covering the titanium mesh is 5×8cm activated carbon fiber, and the self-made cathode and anode are Ti / IrO 2 Combined with carbon fiber, the aeration flow rate is 0.5L / min, and the reaction time is 120min.

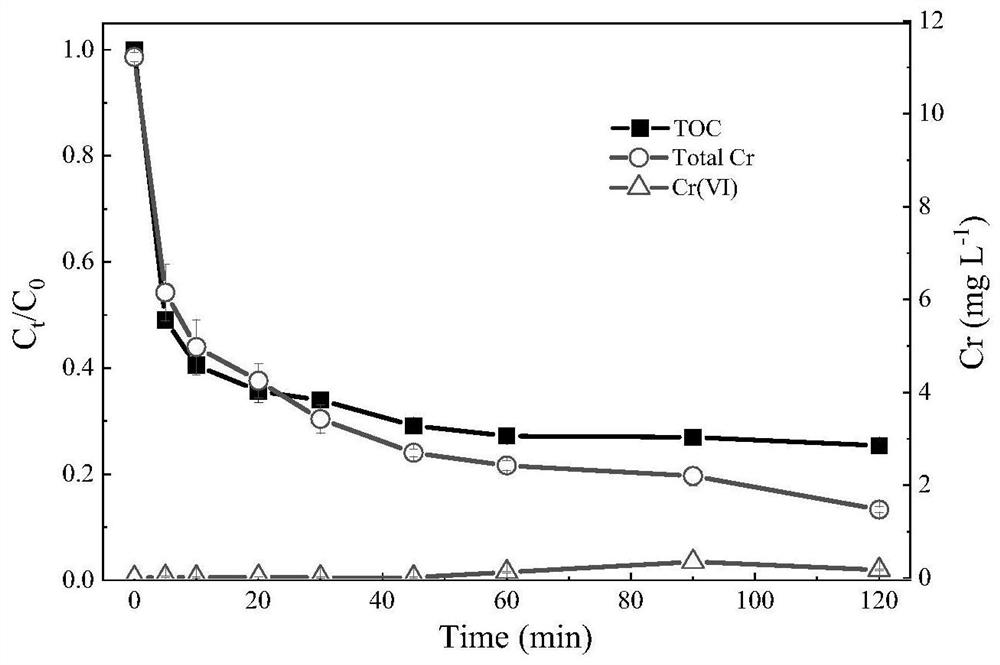

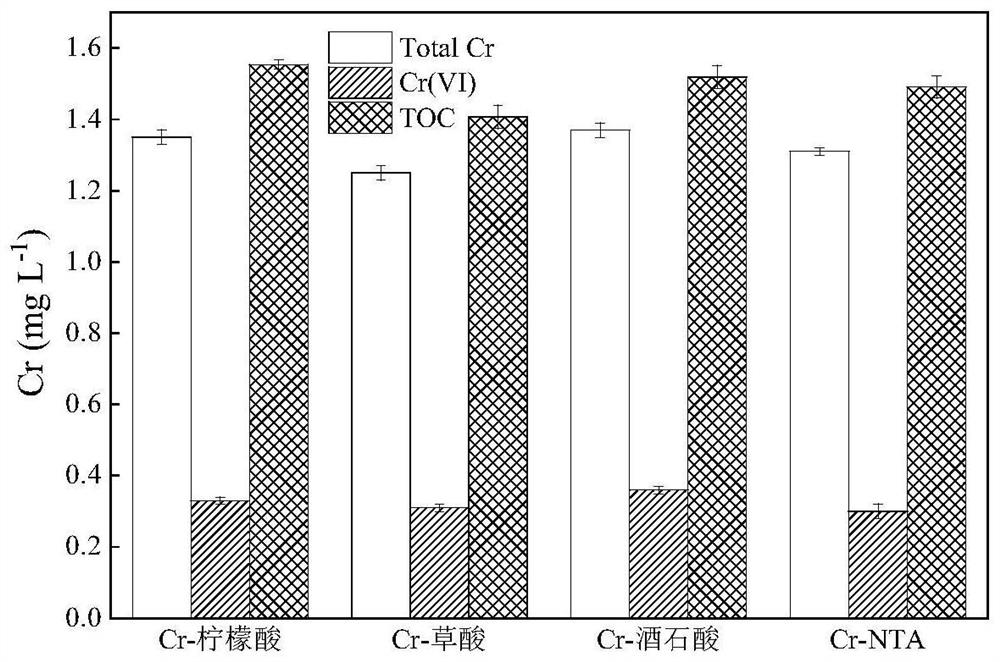

[0056] Experimental results: if figure 1 As shown, after 120 minutes of reaction, the total chromium was reduced to 1.35 mg / L, the concentration of Cr(VI) was 0.22 mg / L, and the removal rate of total organic carbon (TOC) was 73%.

[0057] It can be seen from the experimental results that the residual concentration of total chromium in the solution is lower than 1.5 m...

Embodiment 2

[0059] A method of treating organic complexed chromium wastewater and synchronously controlling the generation of hexavalent chromium in this embodiment is to prepare three parts of Cr-EDTA wastewater with tap water at a concentration of 0.2mmol / L, and adjust the pH to 3±0.02 by HCl / NaOH. The current density is respectively 10, 15, 20mA / cm 2 , the dosage of ozone is 7.4mg / L, the self-made cathode and anode electrodes are 5×8cm titanium mesh, the material covering the titanium mesh is 5×8cm activated carbon fiber, the self-made anode is a combination of Ti and carbon felt, and the self-made cathode is stainless steel Combined with graphite felt, the aeration flow rate is 0.5L / min, and the reaction time is 120min.

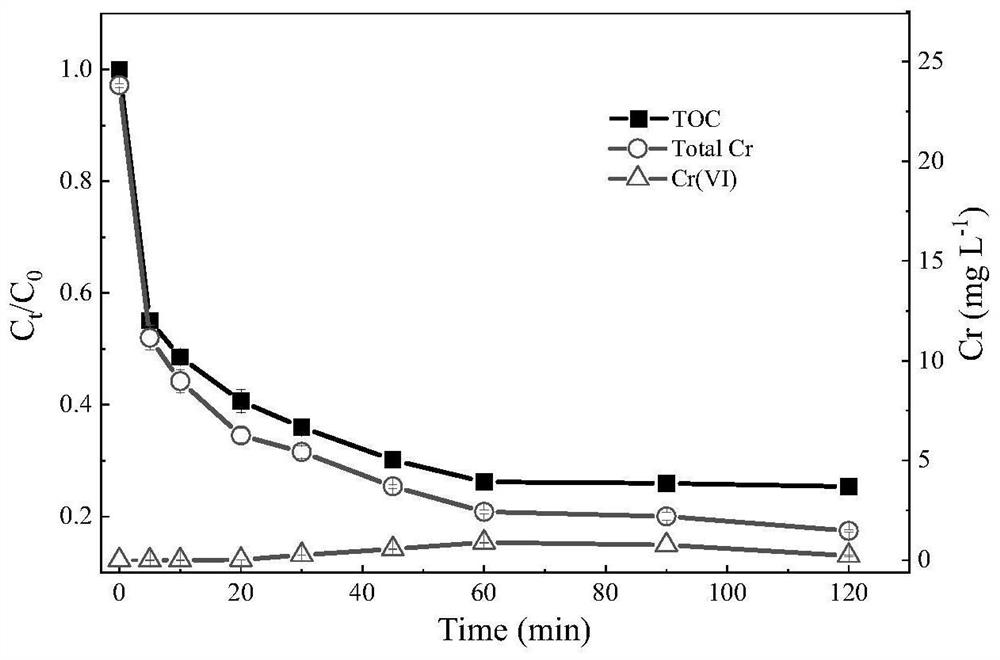

[0060] Experimental results: the current density is 10mA / cm 2 After 120 minutes of reaction, the total chromium in the solution was reduced to 3.25mg / L, Cr(VI) was generated to 0.75mg / L, and the removal rate of TOC was 77%; the current density was 15mA / cm 2 After 1...

Embodiment 3

[0063] A method of treating organic complexed chromium wastewater and synchronously controlling the generation of hexavalent chromium in this embodiment is to prepare three parts of Cr-EDTA wastewater with tap water at a concentration of 0.2mmol / L, and adjust the pH to 3±0.02 by HCl / NaOH. The current density is 15mA / cm 2 , the dosage of ozone is 2.4, 7.4, 15.6mg / L respectively, the self-made cathode and anode electrodes are 5×8cm titanium mesh, the material covering the titanium mesh is 5×8cm activated carbon fiber, the self-made anode is Pt and mesh glass Combination of Carbon, Homemade Cathode as TiO 2 Combined with PTFE carbon, the aeration flow rate is 0.5L / min, and the reaction time is 120min.

[0064] Experimental results: the dosage of ozone is 2.4mg / L, after 120 minutes of reaction, the total chromium in the solution is reduced to 2.80mg / L, Cr(VI) is generated to 0.05mg / L, and the removal rate of TOC reaches 67%. After 120 minutes of reaction, the total chromium in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com