A laser prefabricated micro-texture assisted ultrasonic milling process method and processing system

A micro-texture and laser pretreatment technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem of small depth of cut and feed speed, difficulty in greatly improving processing efficiency, limitations of tool wear resistance and toughness, etc. and other problems, to achieve the effect of diversification of structural configuration, improvement of material removal rate, and reduction of tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

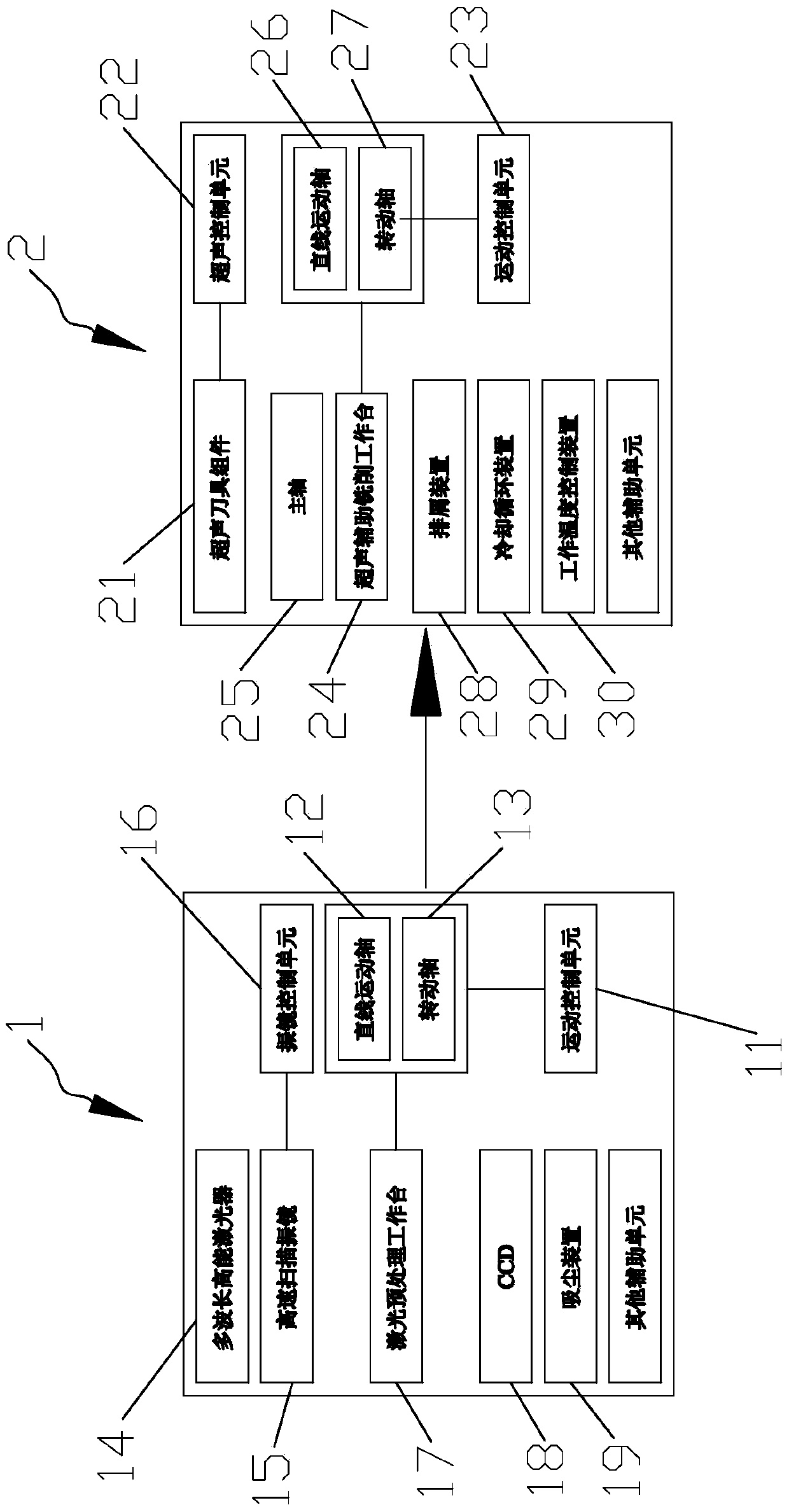

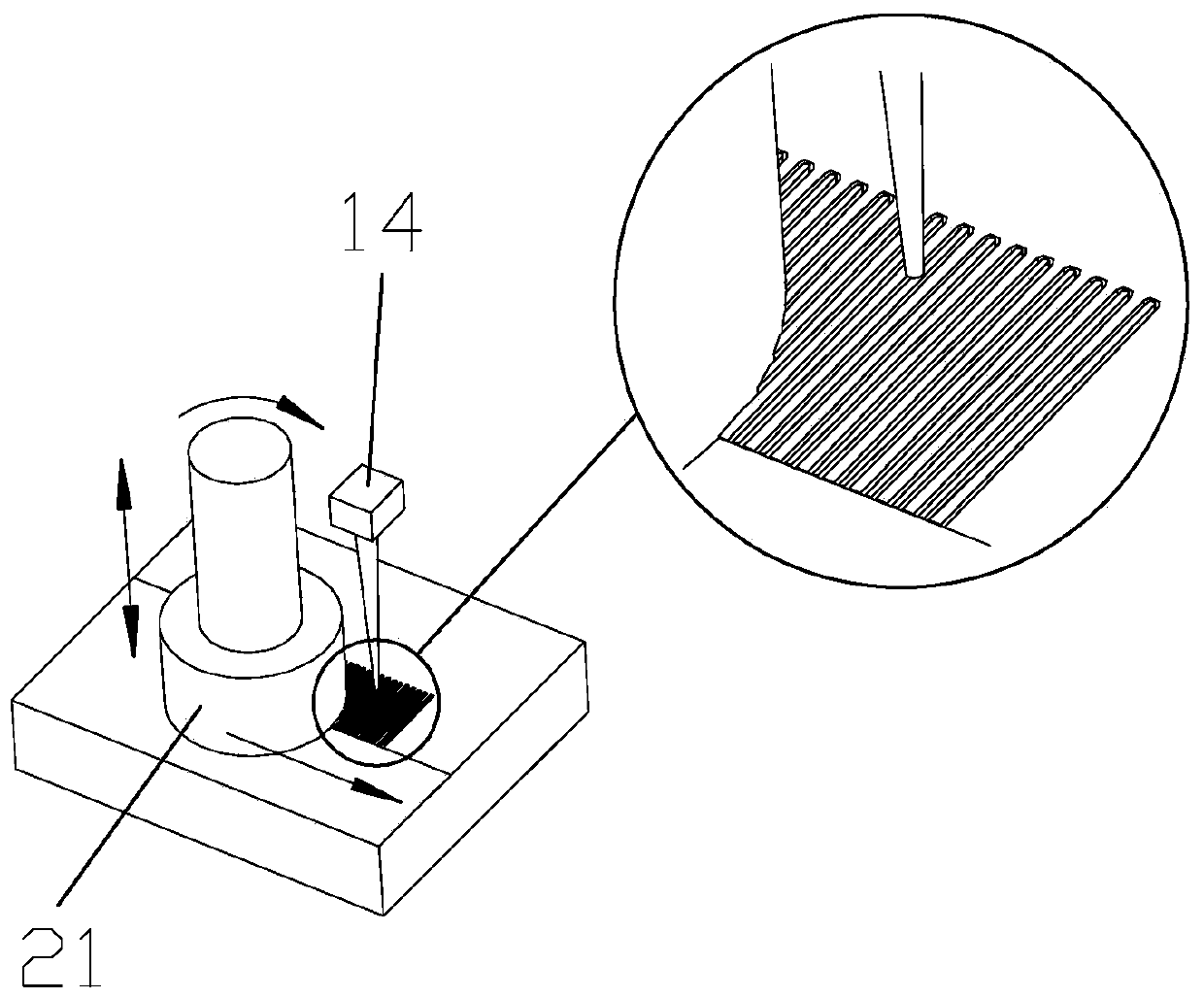

[0039] see figure 1 , the laser prefabricated micro-texture-assisted ultrasonic milling processing system provided by the present invention includes a multi-axis linkage laser processing system 1 and a multi-axis linkage ultrasonic-assisted milling processing system 2, wherein the multi-axis linkage laser processing system 1 is used for the material to be processed Laser pretreatment is performed to form a prefabricated micro-texture on the material to be processed, and the multi-axis linkage ultrasonic-assisted milling system 2 is used to mill the material to be processed after laser pretreatment to form the desired product. The prefabricated micro-textures include vertical micro-groove arrays, chute arrays with a certain angle to the feed direction, grid arrays, circular hole arrays, curved groove arrays, and horizontal micro-groove arrays (see Figure 5A-5F for details).

[0040] The multi-axis linkage laser processing system 1 includes a first motion control unit 11, three ...

Embodiment 2

[0053] The functional structure of the laser prefabricated microtexture assisted ultrasonic milling processing system in this embodiment is basically the same as that of the laser prefabricated microtexture assisted ultrasonic milling processing system in Embodiment 1. The difference is that the multi-axis linkage laser processing system 1 and the multi-axis linkage ultrasonic-assisted milling processing system 2 in this embodiment are integrated online to realize dynamic synchronous large-scale matching processing, and the degree of freedom of rotation of the material to be processed relative to the ultrasonic tool is determined by The swing of the ultrasonic-assisted milling table 24 of the multi-axis linkage ultrasonic-assisted milling processing system 2 is realized, and the spatial attitude of the material to be processed after laser pretreatment relative to the laser beam is realized by the swing of the laser beam.

[0054] In the working state, the laser beam of the mult...

Embodiment 3

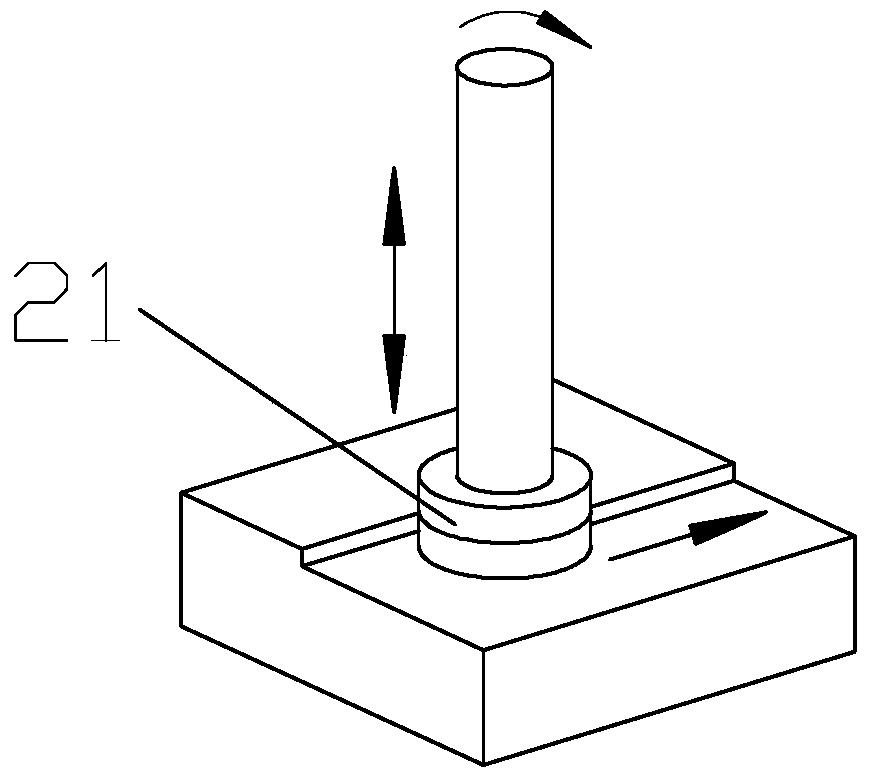

[0057] The functional structure of the laser prefabricated microtexture assisted ultrasonic milling processing system in this embodiment is basically the same as that of the laser prefabricated microtexture assisted ultrasonic milling processing system in Embodiment 2. The difference is that the degree of freedom of rotation of the material to be processed relative to the ultrasonic tool after laser pretreatment is realized by the swing of the spindle 25 of the multi-axis linkage ultrasonic-assisted milling system 2, and the spatial attitude of the material to be processed relative to the laser beam is determined by the laser beam swing implementation.

[0058] Compared with the structure shown in Embodiment 2, this structure is more suitable for processing large-scale structural workpieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com