Method for recycling copper oxide and zinc oxide from organosilicon spent contact mass

A technology of organosilicon waste contact body and copper oxide, which is applied in copper oxide/copper hydroxide, chemical instruments and methods, zinc oxide/zinc hydroxide, etc., can solve the problems of secondary environmental pollution treatment cost, complex process flow, etc. , to achieve the effect of being conducive to large-scale treatment, high economic benefits, and no three-waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

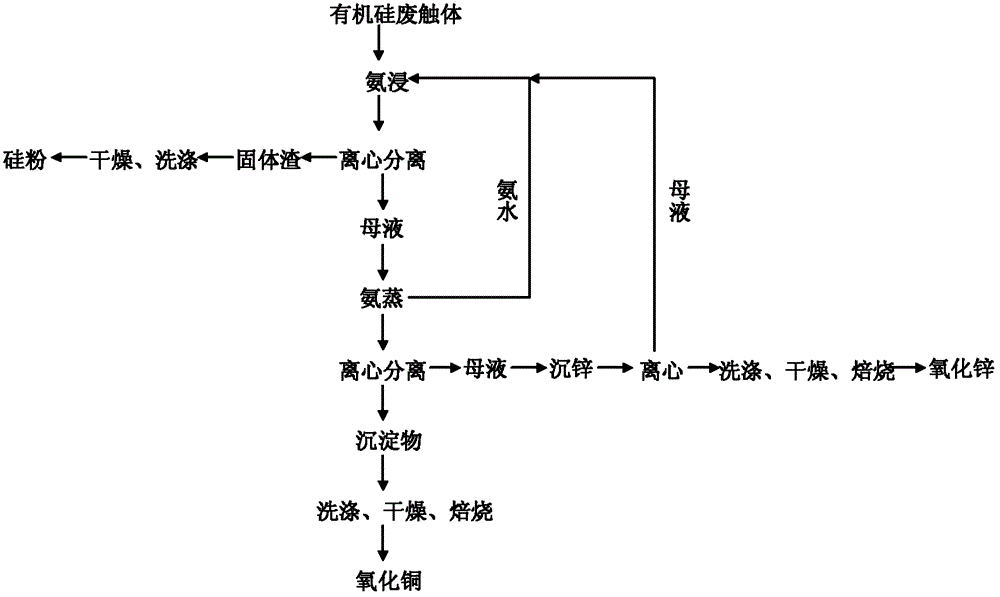

Method used

Image

Examples

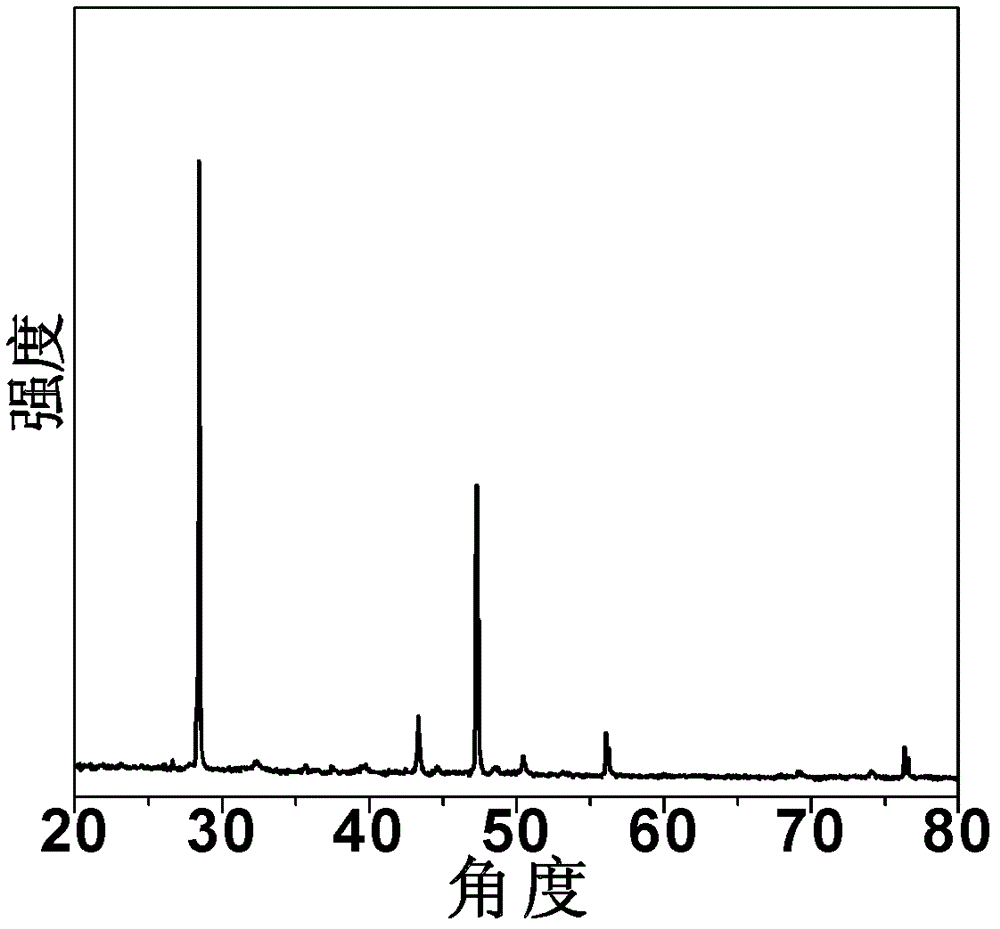

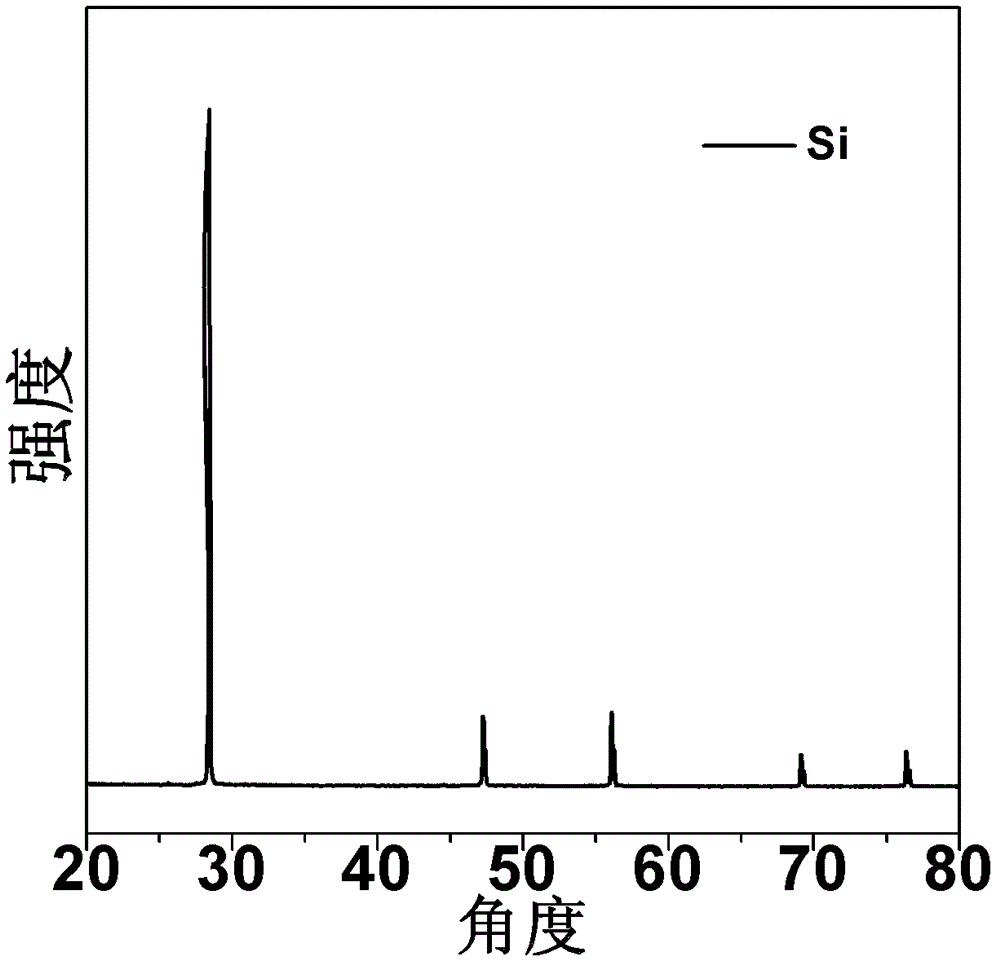

Embodiment 1

[0034]72.0kg of ammonia (25.0wt%) and 34.0kg of ammonium carbonate are added to 250.0kg of water to form a mixed solution (the mol ratio of ammonia to ammonium carbonate is 3.0), and then 100.0kg of waste contacts (containing copper 15.0wt%, zinc 1.5wt%, the mass ratio of ammonia-ammonium salt to waste contact body is 1.06), and stirred in air at 20°C for 8h. After filtering or centrifuging, the solid slag was washed and dried to obtain 80.0kg of silicon powder. Raise the temperature of the mother liquor after centrifugation to 40°C and keep it warm for 10 hours. A large amount of blue-green precipitates will be produced in the solution. At the same time, the released ammonia gas can be absorbed by 10wt% ammonia water and can be recycled as a raw material for impregnating waste contacts. After filtration or centrifugal separation, the precipitate was washed, dried, and calcined at 450° C. for 5 hours to obtain 18.0 kg of finished copper oxide with a purity of 97% and a total re...

Embodiment 2

[0041] 80.0kg of ammonia water (25.0wt%) and 45.0kg of ammonium carbonate are added to 200kg of water to form a mixed solution (the mol ratio of ammonia to ammonium carbonate is 2.5), and then 100.0kg of waste contacts (containing copper 15.0wt%, zinc 1.5 wt%, the mass ratio of ammonia-ammonium salt to waste contact body is 1.25), stirred at 70°C with air for 6h, filtered or centrifuged, washed and dried the solid slag to obtain 78.0kg of silicon powder. Raise the temperature of the separated mother liquor to 80° C. and keep it warm for 5 hours. A large amount of blue-green precipitates will be produced in the solution. At the same time, the released ammonia gas can be absorbed by 10wt% ammonia water and can be recycled as a raw material for impregnating waste contacts. After filtration or centrifugation, the precipitate was washed, dried, and calcined at 500°C for 4 hours to obtain 18.5kg of finished copper oxide with a purity of 96% and a total recovery of 98%. Add 3.5kg of ...

Embodiment 3

[0043] Add 91.0kg of ammonia water (25.0wt%) and 40.0kg of ammonium carbonate into 200kg of water to form a mixed solution (the mol ratio of ammonia to ammonium carbonate is 3.2), then add 100.0kg of waste contacts (containing copper 15.0wt%, zinc 1.5 % by weight, the mass ratio of ammonia-ammonium salt to waste contact body is 1.31), stirred at 100° C. with air for 1 h, filtered or centrifuged, washed and dried the solid slag to obtain 79.5 kg of silicon powder. Raise the temperature of the mother liquor after centrifugation to 100°C and keep it warm for 1 hour. A large amount of blue-green precipitates will be produced in the solution. At the same time, the released ammonia gas can be absorbed by 10wt% ammonia water and can be recycled as a raw material for impregnating waste contacts. After filtration or centrifugation, the precipitate was washed, dried, and calcined at 500°C for 6 hours to obtain 18.2kg of finished copper oxide with a purity of 96% and a total recovery of 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com