A kind of method for plasticizing biomass composite material with low melting point chitosan microspheres

A technology for chitosan microspheres and biomass materials, which is applied in the field of polymer material preparation, can solve the problems of being difficult to dissolve, difficult to process and form, and achieve the effects of avoiding degradation, improving mechanical properties, and avoiding poor mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

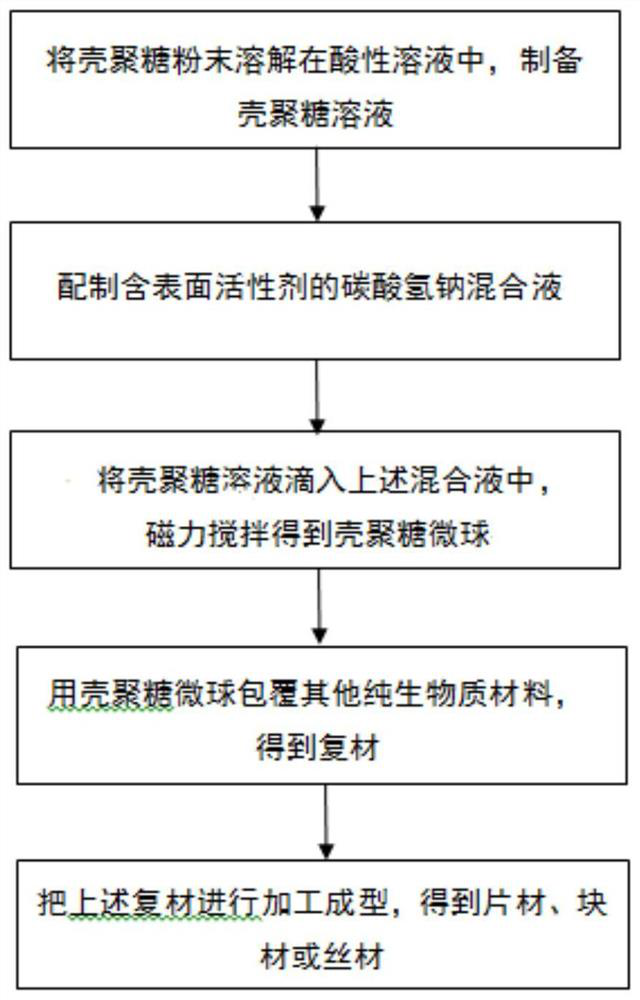

Method used

Image

Examples

Embodiment 1

[0026] (1) Prepare materials, prepare chitosan, concentrated hydrochloric acid, sodium bicarbonate and sodium lauryl sulfate;

[0027] (2) To prepare chitosan solution, first dilute concentrated hydrochloric acid to 1% dilute hydrochloric acid solution, add an appropriate amount of chitosan powder, mechanically stir to obtain chitosan solution, the rotating speed is 500r / min, and stir for 1 hour;

[0028] (3) To prepare chitosan microspheres, first add a small amount of sodium lauryl sulfate powder into the sodium bicarbonate solution to obtain a mixed solution; then drop the chitosan solution into the above-mentioned sodium bicarbonate mixed solution, and use Mechanical stirring, obtains the chitosan microsphere that separates out;

[0029] (4) Ultrasonic dispersion is carried out to the mixed solution containing chitosan microspheres to further refine the particle size, the ultrasonic time is preferably 30min, and the ultrasonic power is preferably 300W, and then the solutio...

Embodiment 2

[0032] (1) prepare materials, prepare chitosan, acetic acid, sodium bicarbonate and sodium lauryl sulfate;

[0033] (2) To prepare chitosan solution, first dilute acetic acid to 1% acetic acid solution, add an appropriate amount of chitosan powder, mechanically stir to obtain chitosan solution, the rotating speed is 300r / min, and stir for 2 hours;

[0034] (3) To prepare chitosan microspheres, first add a small amount of sodium lauryl sulfate powder into the sodium bicarbonate solution to obtain a mixed solution; then drop the chitosan solution into the above-mentioned sodium bicarbonate mixed solution, and use Mechanical stirring, obtains the chitosan microsphere that separates out;

[0035] (4) Ultrasonic dispersion is carried out to the mixed solution containing chitosan microspheres to further refine the particle size, the ultrasonic time is preferably 30min, and the ultrasonic power is preferably 300W, and then the solution freeze-drying after the ultrasonic wave is obtai...

Embodiment 3

[0038] (1) prepare materials, prepare chitosan, formic acid, sodium bicarbonate and sodium lauryl sulfate;

[0039] (2) To prepare chitosan solution, at first dilute formic acid to 1% formic acid solution, add an appropriate amount of chitosan powder, mechanically stir to obtain chitosan solution, the rotating speed is 300r / min, stir for 2 hours;

[0040] (3) To prepare chitosan microspheres, first add a small amount of sodium lauryl sulfate powder into the sodium bicarbonate solution to obtain a mixed solution; then drop the chitosan solution into the above-mentioned sodium bicarbonate mixed solution, and use Mechanical stirring, obtains the chitosan microsphere that separates out;

[0041] (4) Ultrasonic dispersion is carried out to the mixed solution containing chitosan microspheres to further refine the particle size, the ultrasonic time is preferably 30min, and the ultrasonic power is preferably 300W, and then the solution freeze-drying after the ultrasonic wave is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com