Electrochemical treatment method of maleic anhydride acid water

A treatment method and electrochemical technology, applied in chemical instruments and methods, water/sewage treatment, natural water treatment, etc., can solve the problems of waste acid water treatment efficiency, secondary pollution, economy, etc., to prevent corrosion problems and avoid costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

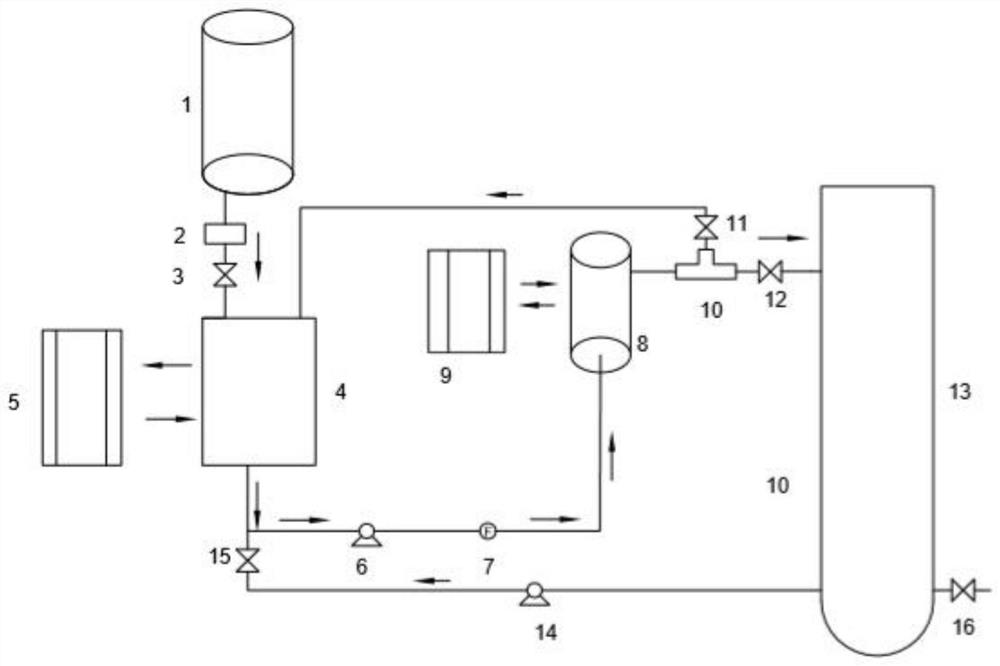

Method used

Image

Examples

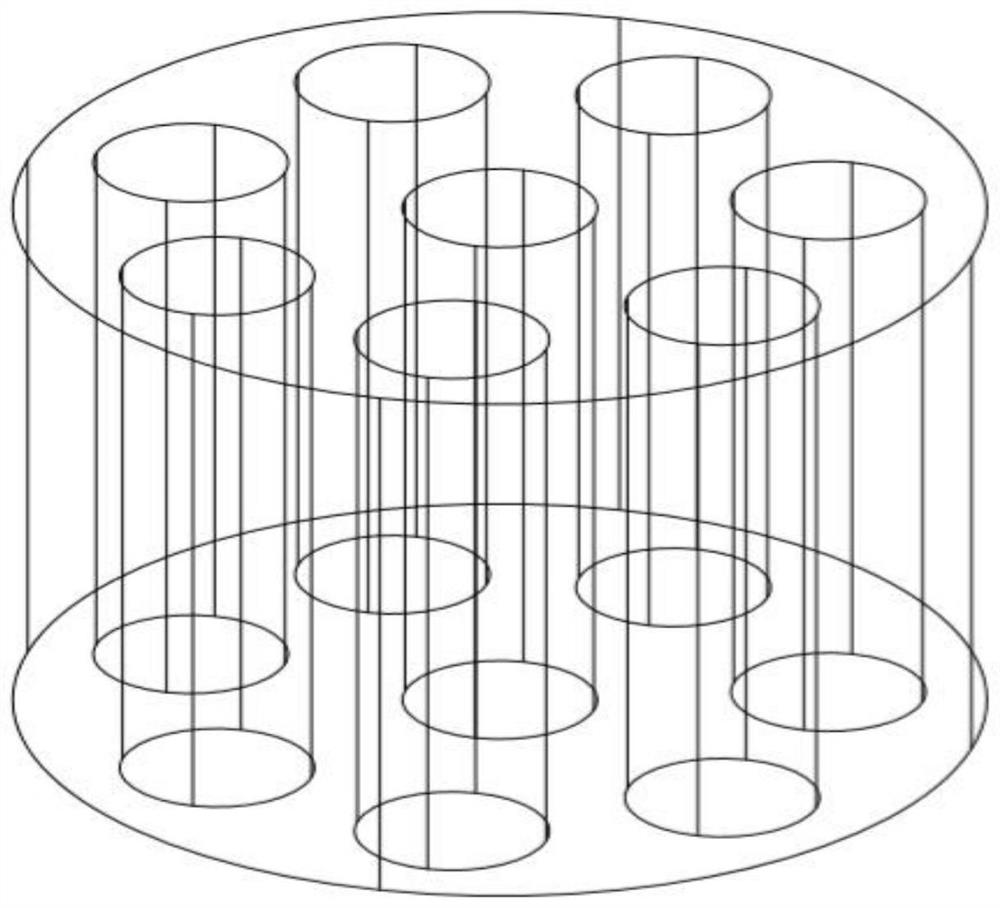

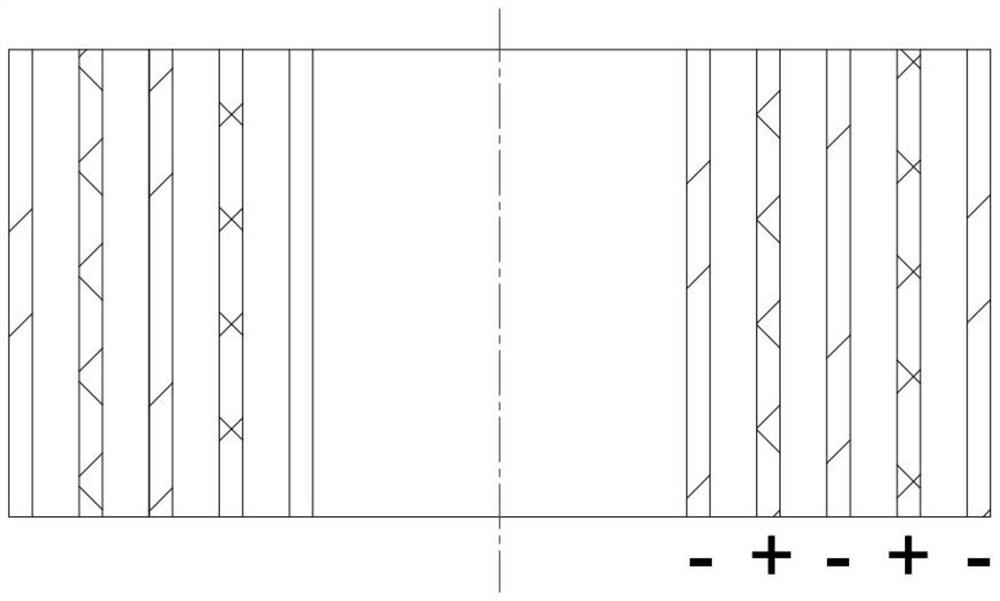

Embodiment 1

[0063] Take 500g of waste acid solution and heat it to 40°C, which contains 122.36g of maleic acid, 0.423g of fumaric acid, 7.13g of formic acid, 7.85g of acetic acid, and 8.21g of propionic acid. The cathode uses Pb electrode and the anode uses Ru-Ir / Ti-coated electrodes, the area of a single tube electrode is 0.0025m 2 ,, the number of tubes is 8, the current density is 1000A / m 2 . According to the calculation, electrolysis needs to be divided into two stages, and the electrolysis time is 1.5h and 1.3h respectively. After the second-stage electrolysis, the solid obtained by the second crystallization was dried to obtain 94.86 g of succinic acid solid, the purity of succinic acid was 98.3%, and the recovery rate of maleic acid was 74.9%. The filtrate was taken for analysis, which contained 10.41 g of maleic acid, 20.22 g of succinic acid, 0.324 g of fumaric acid, 6.35 g of formic acid, 6.87 g of acetic acid, and 7.31 g of propionic acid.

Embodiment 2

[0065] Take 500g of waste acid solution and heat it to 40°C, which contains 122.36g of maleic acid, 0.423g of fumaric acid, 7.13g of formic acid, 7.85g of acetic acid, and 8.21g of propionic acid. The cathode uses Pb electrode and the anode uses PbO 2 / Ti coated electrode, the area of a single tube electrode is 0.0025m 2, , 8 tubes, current density 1000A / m 2 . According to the calculation, electrolysis needs to be divided into two stages, and the electrolysis time is 1.5h and 1.3h respectively. After the second-stage electrolysis, the solid obtained by the second crystallization was dried to obtain 93.97 g of succinic acid solid, the purity of succinic acid was 98.8%, and the recovery rate of maleic acid was 74.5%. The filtrate was taken for analysis, which contained 11.06g of maleic acid, 20.54g of succinic acid, 0.401g of fumaric acid, 4.05g of formic acid, 5.77g of acetic acid, and 5.58g of propionic acid.

Embodiment 3

[0067] Take 500g of waste acid solution and heat it to 40°C, which contains 122.36g of maleic acid, 0.423g of fumaric acid, 7.13g of formic acid, 7.85g of acetic acid, and 8.21g of propionic acid. The cathode uses Pb electrode and the anode uses Sn-PbO 2 / Ti coated electrode, the area of a single tube electrode is 0.0025m 2, , 8 tubes, current density 1000A / m 2 . According to the calculation, electrolysis needs to be divided into two stages, and the electrolysis time is 1.5h and 1.3h respectively. After the second-stage electrolysis, the solid obtained by the second crystallization was dried to obtain 95.78 g of succinic acid solid, the purity of succinic acid was 99.1%, and the recovery rate of maleic acid was 74.7%. The filtrate was taken for analysis, which contained 10.97g of maleic acid, 21.98g of succinic acid, 0.311g of fumaric acid, 3.05g of formic acid, 4.32g of acetic acid, and 4.13g of propionic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com