Chamfering machine cutter

A chamfering machine and cutting tool technology, which is applied in the direction of lathe cutting tools, milling cutters, manufacturing tools, etc., can solve the problems of cumbersome operation and waste, and achieve the effect of green processing and saving the cost of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

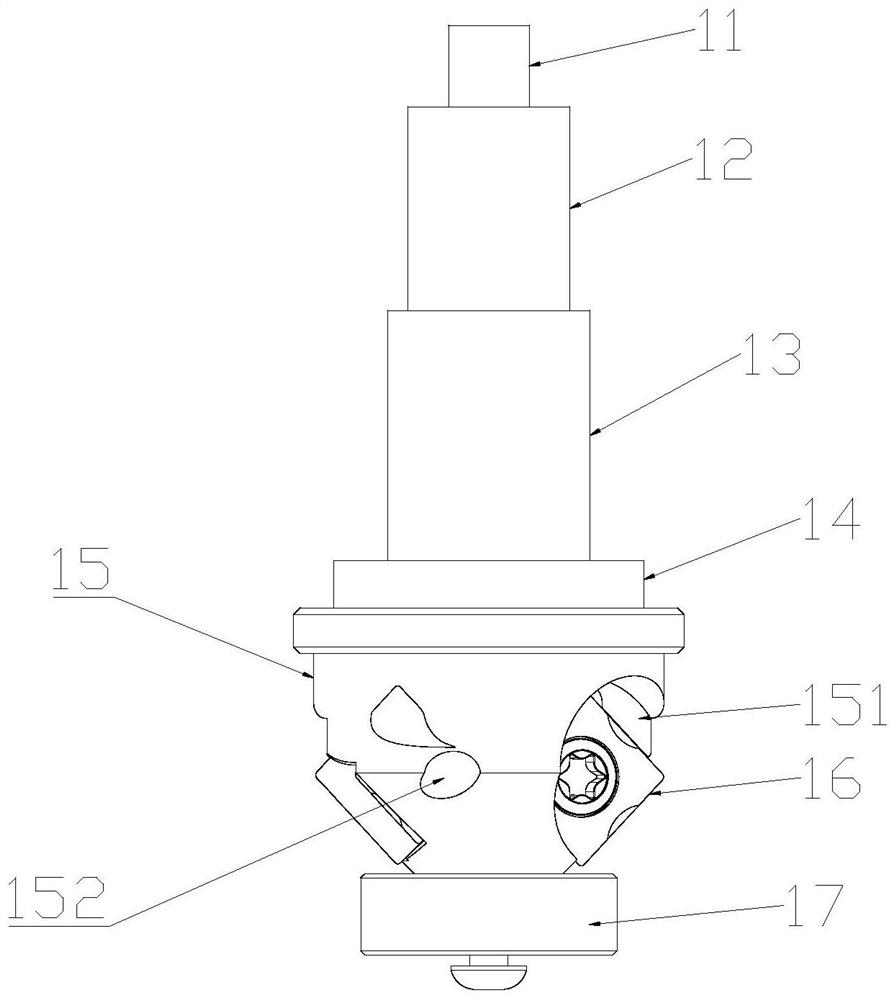

[0014] see figure 1 As shown, the present invention is about a kind of chamfering machine cutter, and it is characterized in that: wherein said cutter comprises handle, several cutter grains 16 for cutting workpiece, wherein one end of handle is connected with the output end of motor, handle The other end of the handle is provided with an assembly groove 151 for two assembling knife grains 16, wherein the knife grain 16 is detachably arranged in the assembly groove 151, and the other end of the handle is also equipped with a rolling bearing 17; wherein the two assembly grooves 151 are about the knife The axis of the handle is symmetrical.

[0015] In this application, the tool includes a knife handle and several cutter grains 16 for cutting workpieces, wherein one end of the knife handle is connected to the output end of the motor, and the other end of the knife handle is provided with an assembly groove 151 for assembling the knife grains 16, wherein The cutter grain 16 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com