A new type of superhard abrasive grinding wheel with high thermal conductivity phase change heat storage and preparation method thereof

A phase-change heat storage, super-hard abrasive technology, applied in the field of grinding wheels, can solve the problems of gas-liquid phase change heat transfer process and efficiency weakening, hindering the movement of the cold end to release heat and condensation, increasing the thermal resistance of the heat pipe, etc. Liquid-to-two-phase conversion efficiency, novel grinding wheel structure, and the effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

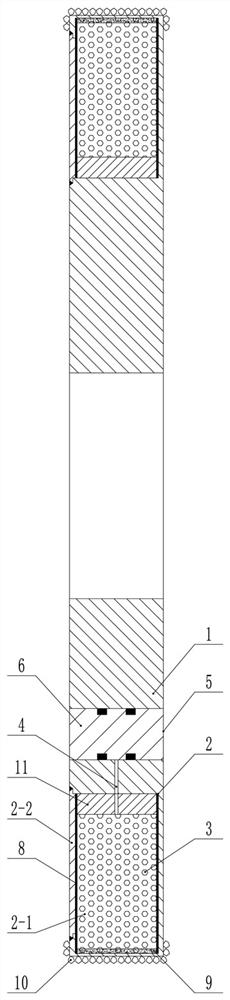

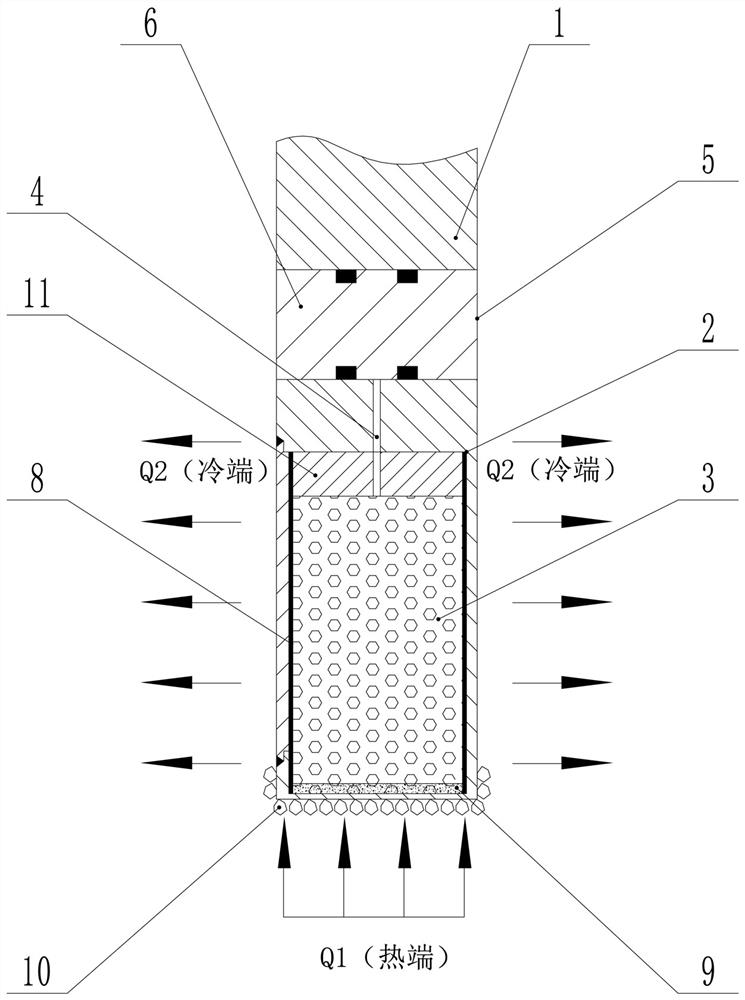

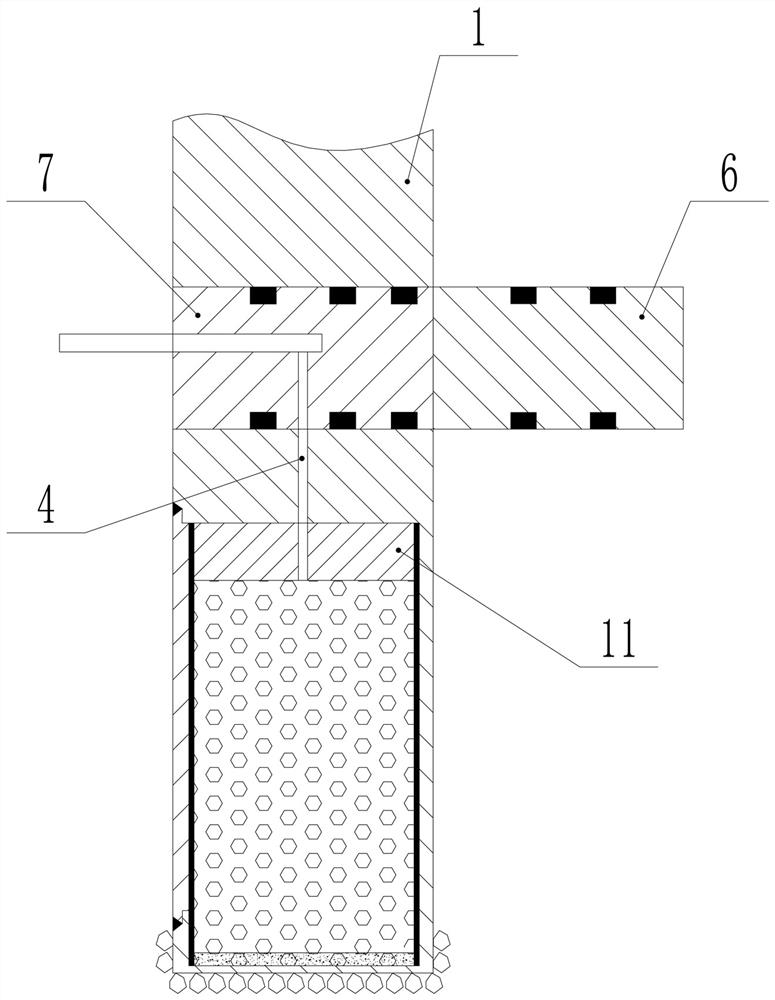

[0036] Such as Figure 1-3 As shown, a new type of high thermal conductivity phase change heat storage superabrasive grinding wheel includes a grinding wheel base 1 and abrasive materials 10. An annular lumen 2 is provided at the inner and outer ends of the grinding wheel base 1, and the annular lumen 2 is filled with There is an annular metal foam 3, such as copper foam, and a gas-liquid phase change heat transfer working medium is also provided in the annular tube cavity 2. The pore diameter of the foam copper is 5-80PPi, and the through-hole ratio is higher than 95%. In this embodiment, due to the step structure at the entrance of the outer peripheral side of the annular lumen, the copper foam cannot completely fill the entire annular lumen, resulting in an assembly gap between the foam copper and the inner side of the annular lumen. Therefore, it is necessary to Metal filling blocks 11 are filled in the gaps. The copper foam 3 and the metal filling block 11 adopt a block-...

Embodiment 2

[0050] A method for manufacturing a novel high thermal conductivity phase change heat storage superabrasive grinding wheel, comprising the following steps:

[0051] 1) According to the design size, make the grinding wheel base, end cover, foam metal, metal filling block, copper foil / graphite composite sheet, vacuum pumping, liquid injection and sealing structure;

[0052] 2) Place the copper foil / graphite composite sheet on one side of the annular lumen in an equal area, attach another copper foil / graphite sheet to one side of the metal foam, and then splice the metal foam into the ring groove After that, apply structural glue on both sides of each metal filling block, insert it into the assembly gap between the copper foam and the grinding wheel base, and connect and fix the three after curing, and fill the structural glue between adjacent metal foams for fixing;

[0053] 3) Assemble the cover plate on the annular groove and weld it;

[0054] 4) Finish the grinding wheel bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com