Comprehensive treatment and reutilization method for industrial inorganic waste salt containing organic pollutants

A technology for comprehensive treatment of organic pollutants, applied in the field of comprehensive treatment and reuse of industrial inorganic waste salt, can solve the problems of uneven heating, difficult high temperature, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

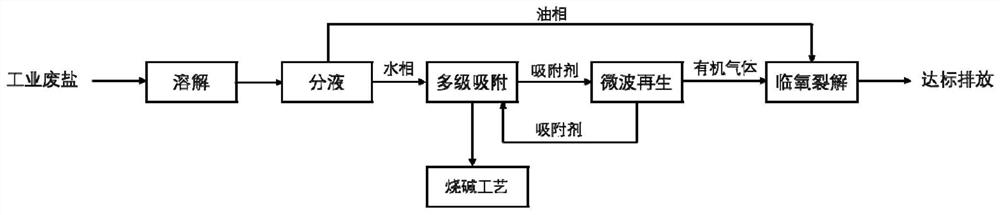

Image

Examples

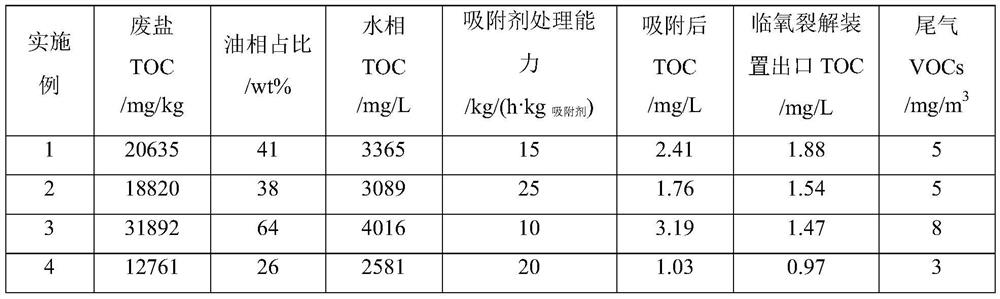

Embodiment 1

[0028] The composition of sodium chloride waste salt to be treated: the mass fraction of sodium chloride is 90%, the mass fraction of ethylene glycol monomethyl ether is 2%, the mass fraction of catechol is 1%, and the mass fraction of benzene is 0.5% , waste salt TOC is 20635mg / kg.

[0029] Such as figure 1, sodium chloride waste salt to be treated is added with water, and stirred at room temperature until no obvious precipitated particles are prepared, and a solution with a mass fraction of sodium chloride of 25% is prepared; The phase accounts for 41wt% of the total organic matter in the sodium chloride waste salt to be treated. The TOC in the water phase obtained by liquid separation is 3365mg / L, and the water phase enters a multi-stage adsorption device composed of 5 adsorption towers connected in series at a flow rate of 150kg / h, and is adsorbed through the adsorption towers from bottom to top. Each adsorption tower is equipped with There are 10kg 40 mesh coconut shell...

Embodiment 2

[0032] The composition of sodium chloride waste salt to be treated: the mass fraction of sodium chloride is 95%, the mass fraction of phenol is 1%, the mass fraction of catechol is 1%, the mass fraction of benzene is 0.5%, and the waste salt TOC is 18820mg / kg.

[0033] Add water to sodium chloride waste salt, stir at room temperature until there are no obvious precipitated particles, and prepare a solution with a mass fraction of sodium chloride of 25%; stand for stratification, separate liquids, and separate the oil phase (4.99kg), which accounts for chlorine 38wt% of sodium chloride waste salt organic matter total amount. The TOC in the water phase obtained by liquid separation is 3089mg / L, and the water phase is sent to a multi-stage adsorption device composed of 5 adsorption towers in series at a flow rate of 250kg / h for adsorption. Each adsorption tower is equipped with 10kgMCM-41 molecular sieve , the processing capacity of MCM-41 molecular sieve is 25kg / (h·kg 吸附剂 ). ...

Embodiment 3

[0036] The composition of sodium chloride waste salt to be treated: the mass fraction of sodium chloride is 92%, the mass fraction of methyl acetate is 2%, the mass fraction of toluene is 1%, the mass fraction of tert-butanol is 1%, n-butanol The mass fraction is 1%, and the TOC in the waste salt is 31892mg / kg.

[0037] Add water to sodium chloride waste salt, stir at room temperature until no obvious precipitated particles, stir and dissolve to prepare a solution with a mass fraction of sodium chloride of 25%; let stand for layering, separate liquids, separate oil phase (14.3kg), oil The phase accounts for 64wt% of the total organic matter of sodium chloride waste salt. The TOC in the aqueous phase obtained by liquid separation is 4016mg / L, and it is sent to a multi-stage adsorption device composed of 5 adsorption towers in series at a flow rate of 100kg / h for adsorption. Each adsorption tower is equipped with 10kg of 40 mesh wooden activated carbon. , the processing capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com