Method for preparing composite copper catalyst by recycling organic silicon waste contacts

A technology for organosilicon waste contact, recovery and treatment, applied in physical/chemical process catalysts, organic chemistry, chemical instruments and methods, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

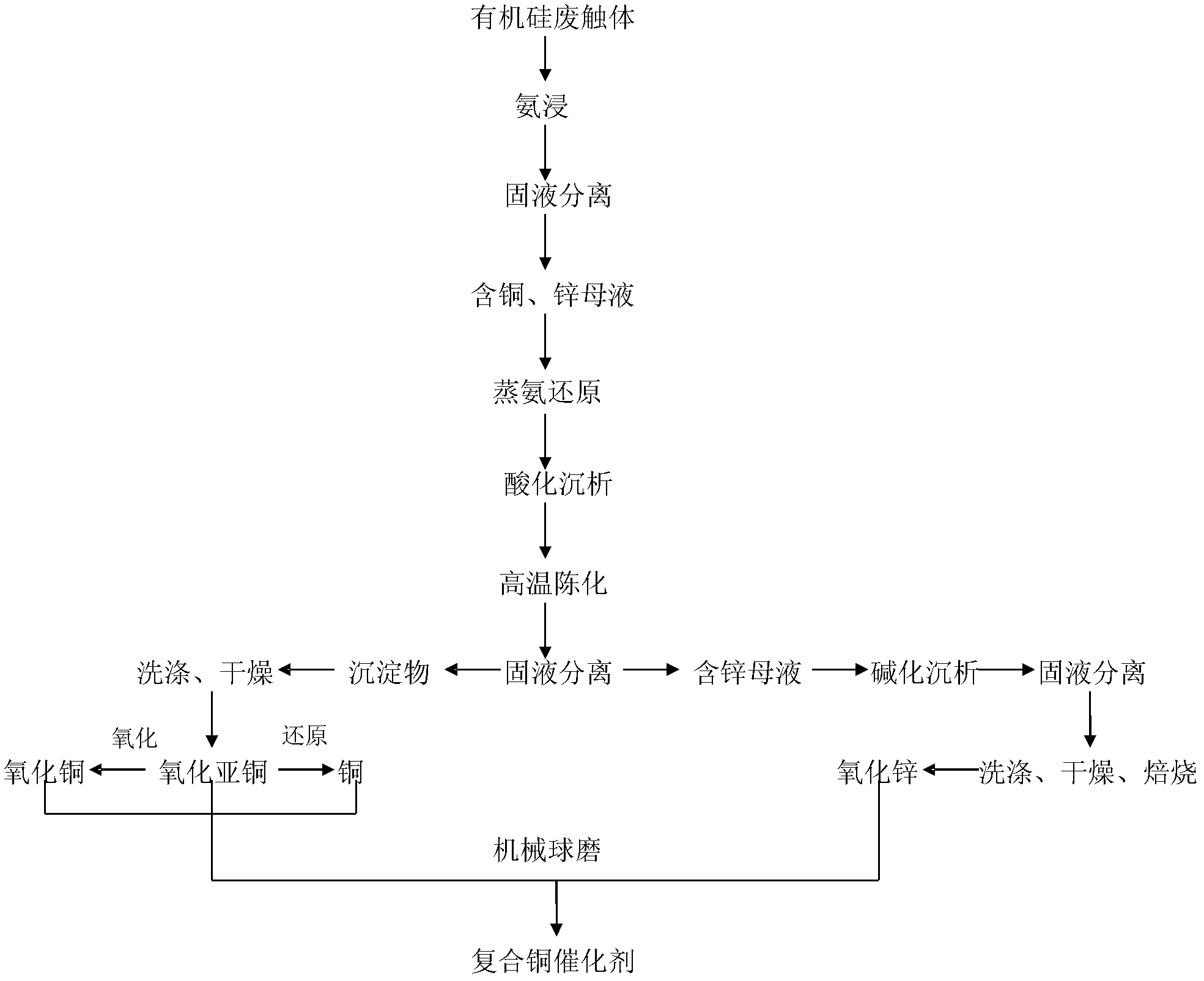

Method used

Image

Examples

Embodiment 1

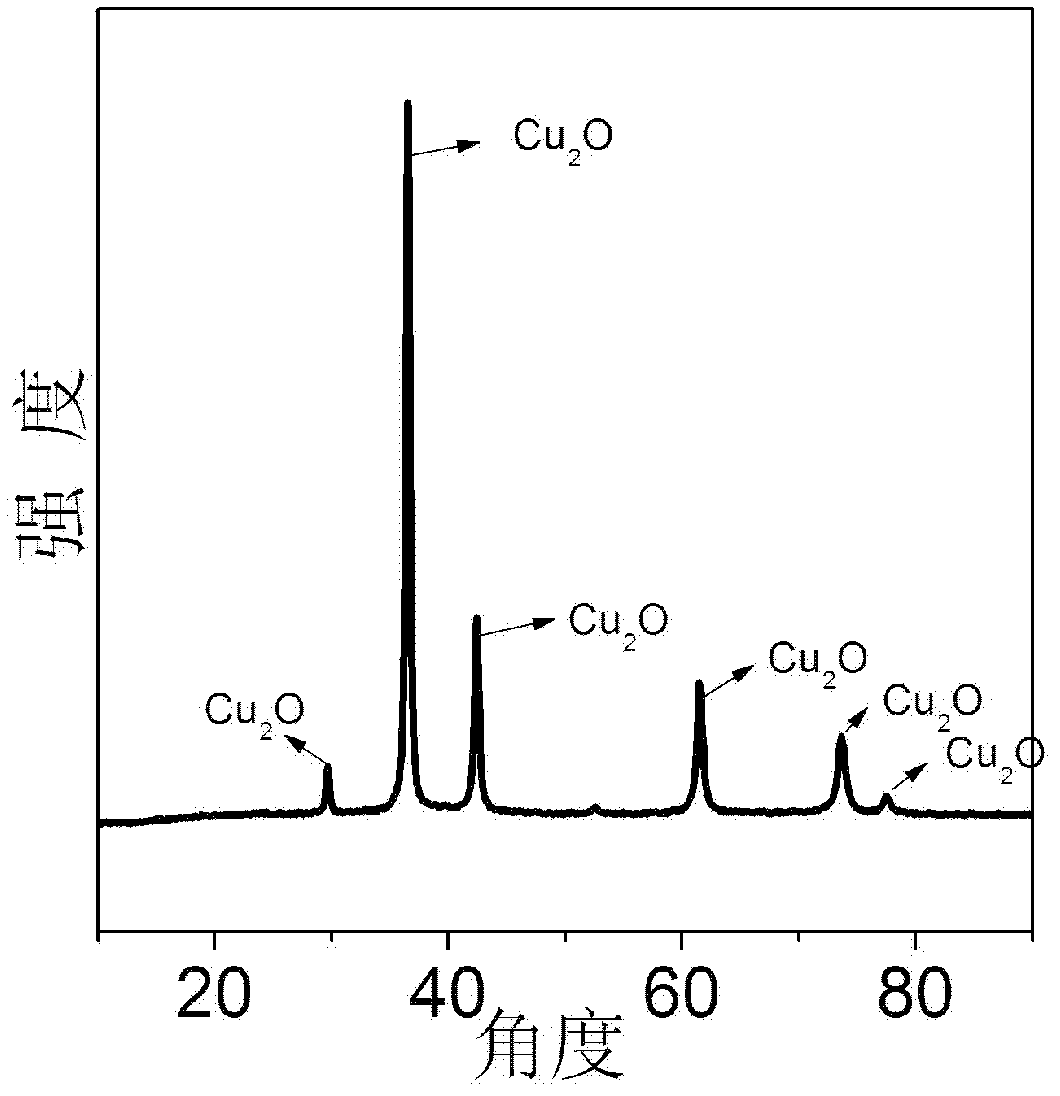

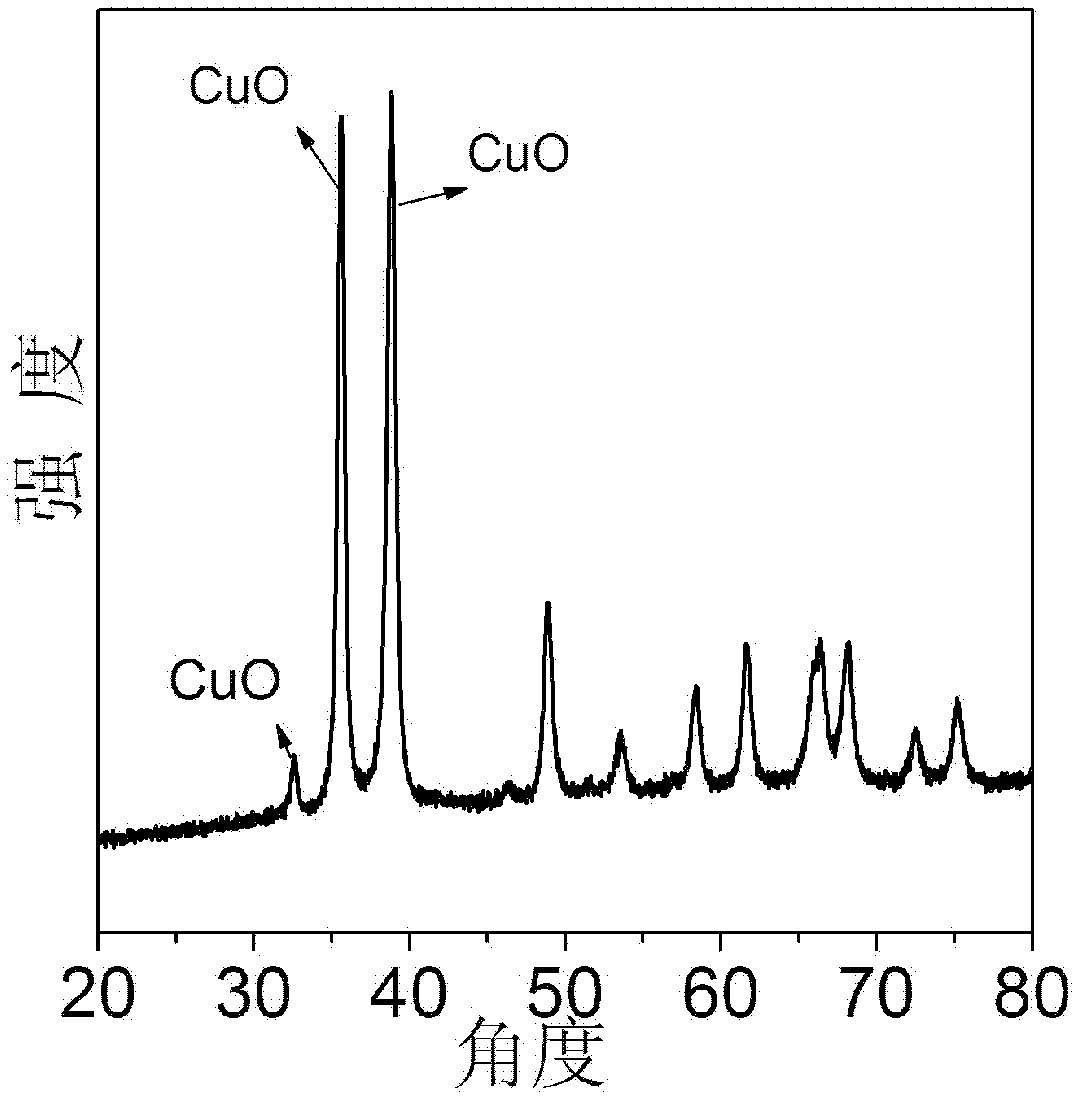

[0077] In a 50L glass-lined reactor, 7.2kg of ammonia water (25.0wt%) and 3.4kg of ammonium carbonate were added to 25.0kg of water to form a mixed solution (the molar ratio of ammonia to ammonium carbonate was 3.0), and then 10.6kg of waste contacts were added. (containing copper 15.0wt%, zinc 1.5wt%), stirred at 50°C with air for 5h, after centrifugation, added 1.6kg of sodium sulfite to the blue mother liquor, then raised the temperature to 70°C, kept it warm for 6h, the released ammonia gas Absorbed with 10wt% ammonia water, it can be recycled as a raw material for impregnating waste contacts. Add 5.0kg of dilute sulfuric acid (sulfuric acid concentration 20.0wt%) to the mother liquor after ammonia distillation, adjust the pH to 3.5, at this time, a large amount of yellow precipitates are precipitated, and then the temperature is raised to 120°C, kept for 8 hours, and the precipitates turn from yellow to brick red. The precipitate was centrifuged, washed and dried to obta...

Embodiment 2

[0089] In a 50L glass-lined reactor, 8.0kg of ammonia water (25.0wt%) and 5.6kg of ammonium carbonate were added to 25.0kg of water to form a mixed solution (the molar ratio of ammonia to ammonium carbonate was 2.0), and then 13.6kg of waste contacts were added. (containing copper 15.0wt%, zinc 1.5wt%), stirred at 40°C with air for 7h, after centrifugation, added 2.0kg of sodium sulfite to the blue mother liquor, then raised the temperature to 80°C, kept it warm for 5h, the released ammonia gas Absorbed with 10wt% ammonia water, it can be recycled as a raw material for impregnating waste contacts. Add 6.0kg of dilute sulfuric acid (sulfuric acid concentration 20.0wt%) to the mother liquor after ammonia distillation, and adjust the pH to 3.0. At this time, a large number of yellow precipitates are precipitated, and then the temperature is raised to 130°C, and the temperature is kept for 6 hours. The precipitate turns from yellow to brick. red. The precipitate was centrifuged, ...

Embodiment 3

[0094] In a 50L glass-lined reactor, 6.0kg of ammonia water (25.0wt%) and 2.1kg of ammonium carbonate were added to 25.0kg of water to form a mixed solution (the molar ratio of ammonia to ammonium carbonate was 4.0), and then 12.9kg of waste contacts were added. (containing copper 15.0wt%, zinc 1.5wt%), stirred at 60°C with air for 1h, after centrifugation, added 1.9kg of sodium sulfite to the blue mother liquor, then raised the temperature to 90°C, kept it warm for 5h, the released ammonia gas Absorbed with 10wt% ammonia water, it can be recycled as a raw material for impregnating waste contacts. Add 4.5kg of dilute sulfuric acid (sulfuric acid concentration: 20.0wt%) to the mother liquor after ammonia distillation to adjust the pH to 4.0. At this time, a large amount of yellow precipitates are precipitated, and then the temperature is raised to 130°C and kept for 6 hours. The precipitates change from yellow to brick. red. The precipitate was centrifuged, washed and dried to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com